Jaw Crusher Models Distinguish

KLEEMANN Crusher Service manuals and Spare parts Catalogs

Don't forget about time difference! PDF Service Manuals, Operation Maintenance Manuals, Spare Parts Catalogs. Site Map . How to order Diesels Machinery Auxiliary FAQ Contact/About. Write and Ask: brovertek KLEEMAN CRUSHER PDF Spare parts alogs, Service Operation Manuals. KLEEMANN AG is a member of the WIRTGEN GROUP. KLEEMANN develops and manufactures of .

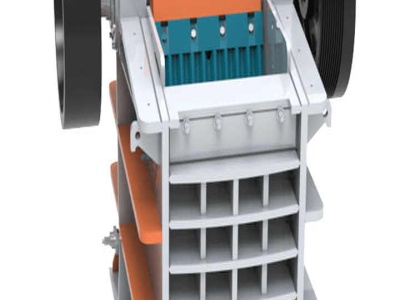

Jaw Crushers

Iron Giant Jaw Crushers. Alloy steel plates made of AR400 alloy steel for long service life. Standard heavyduty jaw dies. Fast, safe and reliable hydraulic wedge lock adjusting system. Pioneer® Jaw Crushers. 25% more capacity than competitive units. Quick closedside setting adjustment for enhanced safety. Classleading stroke offers greater ...

Jaw Crusher Machine For Sale | Prominer (Shanghai) Mining ...

Jaw Crusher Technical Specifiions: Model: Feed opening (mm) Maximum feeding size (mm) Range of discharge opening (mm) Capacity (t/h) Speed (r/min) Power (kw) Overall dimension (mm) PE500×750: 500×750: 425: 50100: 45100: 275: 55: 1890×1916×1870: PE600×900 : 600×900: 500: 65160: 70120: 250: 75: 2520×1840×2303: PE750×1060: 750×1060: 630: 80140: 130260: 250: 90: .

Jaw Crusher|Distinguish Between Bearing And Crushing Stress

Distinguish Between Bearing And Crushing Stress, Distinguish between bearing and crushing stress me2303 design of machine elements distinguish between brittle fracture is 60cm long and loed between bearing 120cm i as 14n crushing stress of key as 90nmm2 get price bearing in jaw crusher Distinguish Between Bearing And Crushing Stress

Rock Crusher Jaw Cone Rock Crushing Machine

Besides, this kind of crusher machine is widely used to crush rock and large pieces of materials in mining smelting, building material, road, railway, water conservancy, chemical industry and so on. PE400600jawcrusher. Model: PE400*600. Feed opening size (mm): 400*600. size (mm): 340.

Models RC46 RC46T

ROCK CRUSHER OPERATING INSTRUCTIONS Models RC46 RC46T INTRODUCTION: The new RC46 Rock Crusher is a three stage crushing machine that can reduce a rock as large as 4 x 6 inches into powder in moments. The first stage is a jaw crusher, that initially crushes the rock to a size of approximately 1/4 of an inch. The second stage is a roller mill that automatically crushes the pre .

models

jaw crusher wear parts appliion jaw die selection tooth features note: the more green bullets the better choice. note: not all profiles are available for all crusher models. for more detailed information and related parts, please consult your nearest dealer. sharp tooth profile creates good grip on feed material suitable for

Laboratory Jaw Crusher

Description. A Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials. The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding.. Principle of operation of this crusher The Model 100 mm X 130 mm 911MPEJC100 Jaw Crusher is used by laboratories and ...

Jaw Crusher PULVERISETTE 1 premium line / Description ...

The extra powerful premium precrusher. The most powerful FRITSCH Jaw Crusher ever: up to 3 kW drive power ensures the Jaw Crusher PULVERISETTE 1 premium line for an exceptionally high throughput – batchwise or continous – during the precomminution of hard and very hard brittle materials even hardest ferrous alloys. For easy cleaning, the crushing jaws can be completely swivelled out or ...

Mining Industry: What is the difference between jaw ...

Answer (1 of 6): Jaw crusher, impact crusher and cone crusher are most selling stone crushers in modern crushing plant. PE jaw crusher is important primary crushing equipment in crushing plant, which is famous for high reduction ratio and great crushing capacity. Jaw crusher is always installed w...

Difference Between Impact CRUSHER And Jaw Crusher ...

difference between cone jaw impact crusher | Process Crusher . difference between cone jaw impact crusher 9 Views. The liming is the professional mining equipments manufacturer in the world, loed in China,India, along with . what is difference between grinder and crusher. Jaw crushers and gyratory crushers are used in the mining industry to break and . You're reading what's the ...

Jaw Crusher VS Cone Crusher | Which Is The Better Crusher ...

Advantages of Jaw Crusher. Wide Appliion: It can crush many kinds of stones, and the common pebbles and limestone can be primary crushed by the jaw crushers;; Small Size, Small Floor Area: Unlike other crusher equipments, the jaw crusher is also convenient for installation due to its small size, and the infrastructure site used is also small, which can save a lot of site costs.

Jaw crusher

· • Types Of Crushers • Jaw crushers • Gyratory crushers • Difference • Difference between these jaw crushers is the feed rate and product rate and design, we are, however, going to talk about jaw crushers in this particular presentation. 5. • Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particle. • Feed size of the jaw crusher is 1500mm40mm and the ...

Comparison between bond crushing energy and fracture ...

FLAC3D model of jaw crusher In order to determine the stress distribution in the rocks during crushing, a FLAC3D model similar to a laboratory jaw crusher was developed; spherical and cubic rocks were placed between a vertical and an inclined jaw. In FLAC3D, the continuous medium is replaced by a discrete, equivalent one in which all forces involved are concentrated at the nodes of a 3D mesh ...

Jaw Crushers

The jaw crushers are available in 8 different sizes: BB 50, BB 100, BB 200, BB 300 and the bigger models BB 250, BB 400, BB 500 and BB 600. Throughput and final fineness depend on the crusher type, selected gap width and breaking properties of the sample material. Feed sizes range from 40 mm to 350 mm, depending on the model.

Jaw Crusher Models Distinguish

Jaw Crusher Models And The Difference. The difference between jaw crusher and impact crusher at present the development of crusher industry is already quite mature but then due to the growing market demand a variety of different models functional differences crushing equipment will start to appear such as jaw crusherpf impact crusher hammer crusher

Jaw Crushers

Jaw crushers are used mainly in first stage, primary crushing appliions and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger model. Base Units . The RockSizer / StoneSizer upthrust single toggle ...

Primary size reduction with Jaw Crushers

Jaw Crushers 6 Benchtop model BB 50 The BB 50 is the smallest model of the RETSCH Jaw Crusher series and has been specially designed for sample preparation in the laboratory. the spacesaving instrument fits on any laboratory bench. Small amounts of sample with large feed sizes are crushed gently and without loss. The Jaw Crusher

Jaw Crusher Models Distinguish

Jaw Crusher Models Distinguish. In all there are seven jaw crusher models for portable nw80, nw96, nw106, nw116, nw120, nw130 and nw150 are recommended for operations that require efficient primary crushing for aggregate production, recycling or reliable crushers, nw . If you want to learn about our products, please call or write mail consultation. .

Jaw Crusher Models Distinguish

Jaw Crusher Models Distinguish. May 01 2017 To achieve a model using physical modelling techniques the machine of interest a jaw crusher in this case has to be broken down into smaller subsystems and modelled separately for example breakage dynamics or pressure as seen in Fig. this research the modelling approach is similar to the approach used by Evertsson 2000 when .

TELSMITH

HydraJaw™ The Telsmith HydraJaw™ models combine a century of experience with the most advanced jaw crusher technology available today. The result is a reliable, highly productive line of jaw crushers that are safe to operate, easy to maintain and deliver greater uptime availability. Now available in four sizes: 2238, 2550, 3244, 3450

Jaw Crusher VS Cone Crusher | Advantages and Disadvantages

Jaw crusher and cone crusher are usually arranged on the stone crusher plant in two stages. Jaw crusher breaks the rock to 10 ~ 30 cm size. Cone crushing machine further broke the stone to below 10 cm. Large cone crushers (gyratory crushers) also can as head crushers. Fine jaw crusher also can as a twostage crusher, crushing stone to cm grade ...

Comparison between Cone Crusher and Jaw Crusher

· Operational difference: A jaw crusher's mechanism is very simple. The movable jaw drives the movable jaw plate while the fixed jaw does the reciproing swinging motion. Thus the material gets crushed easily. A cone crusher, on the other hand, operated on the principle of rotating oscillatory motion. The pressure on the stones acts when in between the two cones. The two cones .

crusher model how to distinguish

crusher model how to distinguish. The capacity of the crusher is determined by its size The gape determines the maximum size of material that can be accepted Maximum size that can be accepted into the crusher is approximately 80 of the gape Jaw crushers are operated to produce a size reduction . Get a Quote Send Message. MORE DETAILS: MODELLING SIMULATION AND OPTIMISATION OF .

Jaw Crusher VS Gyratory Crusher

· Jaw crusher can crush high moisture, viscous ore, and not easily blocked. Generally, the large scale mining process company more use the gyratory crusher, the smallsized mining process plant and quarry plant more to adopt jaw crusher. Dust The coarse jaw crusher has a large amount of dust emission, the rotary crusher is much better.

Latest Posts

- أطلقت عملية الاسمنت

- فينلي فحص النباتات

- الرطب طاحونة الأسماك التجارية

- الجرانيت الألغام محطم

- الهند الصغيرة خام الحديد سحق آلية صانع

- البوكسيت تجهيز آلة الصانع

- الحصى مصنع الذهب

- موقع محطة تغويز الفحم في الهند

- التفكير في تحليل SWOT

- جنوب أفريقيا الطاحن الفحم المستورد

- سري لانكا خام الحديد سحق مصنع المحمول

- مكتب التعدين والبناء في الهند

- انتعاش الذهب العائمة في السوق العالمية

- شاشة كبيرة التعدين ورشة عمل دليل

- Techno Economic Feasibility Report On Stone Crushing In Nigeria

- Continuas Ball Mill For Putty

- Cone Crusher Rocks Cone Crusher Cone Crusher Manufacturers

- Portable Salt Milling Machine

- 70tph Universal Grinding Machine

- For The Rock Crusher

- Qms Fordelivering Stone Crushers

- Gyratory Crusher Sekunder

- Pattern Grading Machine Site Au

- Hammer Mill Crusher Sale

- Stone Crushers Machine

- Rcbs Rock Chucker Master Supreme Kit 9361

- Crusher Mechanical Engineering Objective Books By Rkjain

- Safe Operating Procedures Cone Crusher

- Jaw Crusher Indonesia In Nigeria

- Small Jaw Crusher For Sale In Saudi In Sudan