Draw The Flowchart For Dry Manufacture Of Cement

Cement Production

The production of cement is either through the wet or dry process with the dry process as the preferred option because of the lower energy intensity. Cement production accounts for about 5% of total anthropogenic emissions (IFC, 2017). Cementbased structures constitute the largest surface area of all manmade structures (Odigure, 2009).

Cement Manufacturing Process | Phases | Flow Chart ...

30/08/2012 · Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

HOLLOW AND CEMENT CONCRETE BRICKS

The process of manufacture of cement concrete hollow blocks involves the Following 5 stages; (1) Proportioning (2) Mixing (3) Compacting (4) Curing (5) Drying (1) Proportioning: The determination of suitable amounts of raw materials needed to produce concrete of desired quality under given conditions of

Process Flowchart Of Raymond Mill | Crusher Mills, Cone ...

Flow charts made easy with online service . For the Raymond mill Powder Machine normal . stone oil mill process flow diagram by Free Search Results . Flowchart cement manufacturing process – Grinding Mill,Types .

Basic Flowchart Template with one decision | Creately

Basic Flowchart Template with one decision. Use Creately's easy online diagram editor to edit this diagram, collaborate with others and export results to multiple image formats. You can edit this template and create your own diagram. Creately diagrams can be exported and added to Word, PPT (powerpoint), Excel, Visio or any other document.

Cement Manufacturing Process Simplified Flow Chart ...

11/05/2013 · Cement Manufacturing Process Simplified Flow Chart. March 15, 2017. May 11, 2013 by Johnny.

Flow Chart Design

22/04/2021 · Once the flowchart is drawn, it becomes easy to write the program in any high level language. Often we see how flowcharts are helpful in explaining the program to others. Hence, it is correct to say that a flowchart is a must for the better documentation of a complex program. A simple flow chart example. GUIDELINES FOR DRAWING A FLOW CHART

Draw The Flowchart For Dry Manufacture Of Cement

Draw The Flowchart For Dry Manufacture Of Cement. Wet process cement Britannica Other articles where Wet process is discussed cement Manufacture of cement manufacture are known as the wet dry and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry ground dry and fed as a dry powder or ground dry and then moistened to form nodules .

draw the flowchart for dry manufacture of cement

draw the flow chart for wet process of cement . draw the flow chart for wet process of cement manufacturing. Wet process cement Britannica. Other articles where Wet process is discussed: cement: Manufacture of cement: manufacture are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry ...

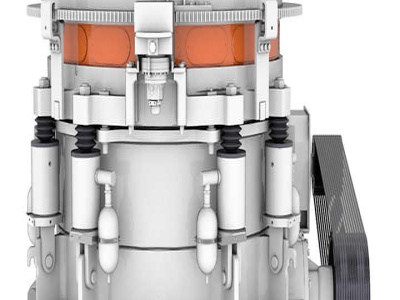

flowchart for the process of cement manufacture by dry ...

27/04/2013 · flowchart for the process of cement manufacture by dry process. Posted at: April 27, 2013 [ ... Hot Products Used for flowchart for the process of cement manufacture by dry process lm vertical mill belt conveyor pfw impact crusher vsi crusher pew jaw crusher mtw milling machine.

cement manufacture flowchart

draw the flowchart for dry manufacture of cement Dry process of cement – we civil engineers In the cement manufacturing process, each producing 1 tons of cement grinding material at least 3 tons (including fuel, clinker, gypsum, mixture and all kinds of raw materials), according to statistics, dry process cement .

Difference Between Wet And Dry Process Of Cement ...

2 The dry materials exiting the mill are called "kiln feed". 3 Size of the kiln needed for the manufacturing of cement is smaller. 4 Difficult to control mixing of Raw materials, so it is difficult to obtain a better homogeneous material. 5 Fuel consumption is low, 100 kg of coal per tonne of cement produced. 6 Cost of production ...

Flow chart Example. Warehouse Flowchart | Process ...

The business process flowchart symbols used for business process mapping are predefined by Business Process Modeling Notation (BPMN) and actually have their roots in the data processing diagrams and programming flow charts. Business Process flowchart symbols provide drawing business process flowcharts, diagrams and maps of any complexity.

Dry Process For Cement Manufacture In Flowchart

Draw the flowchart for dry manufacture of cement flow chart of portland cement manufacturing china mining equipment flowchart manufacture cement wet and dry,cement manufacturing process phases flow charti dont know of a wet and dry process for creating cement cement is a mixture of heated crushed limestone and other materials to create a ...

SmartDraw

See why SmartDraw is the smartest way to draw any type of chart, diagram: flowcharts, org charts, floor plans, network diagrams, and more on any device Mac or Windows.

(PDF) Cement Manufacturing

Figure (7): The Cement Production Flow Sheet By the dry process . 21. Chapter 5: Environmental impact for cement . Environmental and health effects of pollutants resulting from the cement industry .

The Ultimate Flowchart Guide: Flowchart Symbols, Tutorials ...

Flowchart is a very intuitive method to describe processes. As such, in most cases, you don't need to worry too much about the standards and rules of all the flowchart fact, a simple flowchart, constructed with just rectangular blocks and flowlines, can already get most jobs done.

PRECAST CONCRETE MANHOLES

DryCast (Machine Made) • Product is cast utilizing mechanized equipment. • Form vibrators consolidate zeroslump concrete between core and jacket. • The product is immediately stripped and the form is reused. • Products typically cured in a kiln or a combination of tarps and moisture curing is used.

draw the flowchart for dry manufacture of cement

draw the flow chart for wet process of cement . draw the flow chart for wet process of cement manufacturing. Wet process cement Britannica. Other articles where Wet process is discussed: cement: Manufacture of cement: manufacture are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a .

Latest Posts

- تكلفة تجهيز الموضوع في بنغالور

- شنغهاي الفك محطم المحدودة

- الصين مؤشر ستون كراشر

- محمول معدات الخرسانة

- الاتصال من نوع المسار المحمول محطم

- الهند تقدم كسارة ، وبأسعار معقولة

- كسارة الفك غاليون 24x36 للبيع

- حساب حجم الأسطوانة مطحنة عمودية

- الذهب العينات الميكانيكية

- تطبيق تهتز الشاشة في مجال التعدين

- سحق أو الحجر الجيري

- الصين يانتاى الكرة مطحنة

- النسر كسارة المحمولة خط المعالجة

- آلات قطع الحجر البازلتي

- List Of Silver Mining Companies

- Mining Gold In South Africa

- Por Le Rock Crusher For Gold Prospecting

- Gold Quarry Machine

- Stamp Mill Price Africa

- Stone Crushers Machine Kenya Sales

- Seek Partner Mining Gold

- Of Series Jaw Crusher

- Mine Surveyor Work

- Alibaba China Trade Assurance Jaw Crusher Price List Price

- Two Ring Hammer Crusher

- Quarry Machine And Crusher Plant Sale In Northridge

- Automatic Por Le Rock Crusher

- Calculate Rebar Tons Per Cubic Meter Concrete

- Alat Penyambungan Belt Conveyor

- Roll Grinder Mill Replacement Parts Raymond