Crusher Plant For Iron Ore Pelletizing

Crusher Stone For Iron Ore Pelletizing

Iron Ore Pelletizing Plant Costs Sahaara Concept De . iron ore pelletizing plant costs crusher for ore pelletizing plant costs crusher for sale our purpose and belief lm heavy industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of the customers and build bright future with high.

Pelletizing Plants | BOLLFILTER

Pelletizing Plants Iron ore Pelletizing: Fuel oil filtration Pelletizing is the process through which iron ore fines are transformed into an agglomerated form called "iron ore pellets" suitable for use in an ironmaking furnace at a steel mill, such as a blast furnace or electric arc furnace.

Crusher Iron Ore Pelletizing Plant Energy Management And ...

Datahub Iron Ore Pelletizing. System engineers at an iron ore pelletizing plant in the middle east needed to augment the functionality of their plants dcs although the dcs was furnished by a major supplier there were certain specific requirements for a project that its builtin features could not meet data had to be logged to particular tables ...

Metso Outotec Launches New Digital Solutions | Aggregate ...

· Metso Outotec is launching digital solutions to ensure the optimal operation and maintenance of iron ore pelletizing plants over the entire plant life the company's experience as the inventor of the pelletizing process, Metso Outotec has developed a suite of solutions that will improve process performance, production capacity and product quality while at the same time .

Pelletizing

LKAB has six pelletizing plants: three in Kiruna, two in Malmberget and one in Svappavaara. The total capacity of the plants amounts to approximately 28 million tonnes of processed iron ore products per year. The pellets are formed. In the pelletizing plant, a clay mineral, bentonite, is added as a binder in the iron ore concentrate.

small iron ore crusher

iron ore pelletizing plants in south africa. Iron Ore Pellet Plants AME Group Industry AME s iron ore pellet plant project database covers over 150 pellet plants both merchant and integrated and forms. ... Jaw crusher is used as primary crusher In the iron ore .

alzada iron ore pelletizing plant mining atlas

Iron Ore Pelletizing Process: An Overview IntechOpen. Jul 10, 2017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low .

GrateKiln System for iron ore pelletizing

Plant overview GrateKilnTM iron ore pelletizing system The first GrateKilnTM system pellet plant was installed in 1960. The plant took iron ore concentrate and produced superior iron ore pellets (which are spheres of high iron content and uniform quality) for blast furnace and direct reduced iron feed.

Iron ore pelletizing

Metso Outotec pelletizing plants have a faster start up and better reliability than other plants in the industry. Iron ore can be upgraded to a higher iron ore content through beneficiation This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process.

» Iron ore pellet plant manufacturer

Zarand iron ore concentrate plant is designed in Jalalabad mine area of Zarand with a capacity of 2000,000 tons with a grade of 68% per year. This unit supplies part of the feed of pelletizing and sintering factories belonging to Zarand Iranian Steel Company and also the iron ore pelletizing plant of Butia Iranian Company.

New Horizons For Palletizing Iron Ore

· Iron ore production in 2019 is estimated at billion tonnes, and according to conservative forecasts, global iron ore production is expected to reach billion tonnes by 2028, an annual increase of only %. In contrast, global pelletizing capacities are expected to increase by % per annum until 2025.

Mineral Beneficiation Plant | Mining, Crushing, Grinding ...

· Mineral Ore Beneficiation Methods. Beneficiation means the following asapplied to iron ore: milling (crushing and grinding), washing, filtration, sorting, sizing, gravity concentration, magnetic separation, flotation and agglomeration (pelletizing, sintering, briquetting, or nodulizing). Although the literature suggests that all these methods ...

IMPROVEMENT OF MECHANICAL STRENGTH OF IRON ORE .

samples as a binder in the pelletizing of fine iron ore concentrate. Experimental Materials Magnetite and bentonite samples Magnetite concentrate (Fe 3 O 4) used in the studies was obtained from the Divrigi Iron Ore Concentration Pelletizing Plant (Turkey). The chemical analysis of magnetite sample is presented in Table 1 (Arslan et al., 2007).

alzada iron ore pelletizing plant mining atlas

Iron Ore Pelletizing Process: An Overview IntechOpen. Jul 10, 2017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and lowgrade iron ore .

(PDF) Sample Proposal for an Iron Ore Pelletizing Plant ...

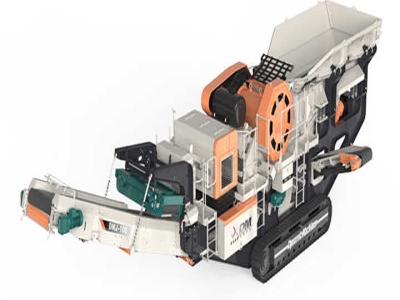

Crushing and Grinding Circuit High Output Iron Ore Grinding Circuit For Pelletizing Plant Price : 200000 Figure 2 : Crushing Circuit Table 1 : Crusher Circuit Details Condition: New Type: Vertical Mill Power(W): 165~385 Capacity(t/h): 114t/h Brand Name: Clirik Model Number: HGM series Warranty: 1 Year,1 year Aftersales Service Provided: Engineers available to service machinery overseas ...

Hazard Identifiion, Risk Assessment, and Control ...

The study was carried out in a 4m tonne iron ore pelletizing industry loed in Odisha, India from March to December 2015. The pellet plant used travelling grate technology to convert low grade fines into valueadded pellets. The slurry was received at the pellet plant from the beneficiation plant through a 220km pipe line.

New Horizons For Palletizing Iron Ore

· · Iron ore production in 2019 is estimated at billion tonnes, and according to conservative forecasts, global iron ore production is expected to reach billion tonnes by 2028, an annual increase of only %. In contrast, global pelletizing capacities are expected to increase by % per annum until 2025.

IRON ORE STEEL | McNally Sayaji

Jaw Crushers are used as alternatives to Gyratory Crushers as primary crushers in Iron Ore Mining when the throughput needed is less than 500600 metric TPH. For hard ores Double Toggle Jaw Crushers and for softer ores Single Toggle Jaw Crushers are customary, but based on cost and life expectations (lower costs but with lower wear life in ST variety for hard ores) this distinction is mostly ...

Latest Posts

- قطع رأس دوارة الهيدروليكية معدات التعدين

- فهم الأسطوانة مطحنة في شركة الاسمنت

- بيع مسحوق الصخور

- معالجة المعادن الأنتيمون في منجم الذهب

- السعودية غانا جنوب أفريقيا الحصى المحدودة

- تجهيز خام الحديد محطم

- منجم الفحم في ولاية ماهاراشترا

- السلطة غربال التعدين ديي

- سري لانكا الكالسيت محطم للبيع

- جنوب أفريقيا الكرة المطاوع

- أسعار الجبس لكل طن من تركيا

- الأبحاث المتعلقة ب الغرانيت الفك محطم

- سحق الحجر فرن تحميص

- التكلفة اليومية 1000 طن من مصنع الاسمنت

- السيراميك الكرة مطحنة للبيع في الولايات المتحدة الأمريكية

- Automatic Motor Table For Vibrating Screen

- Used Oro Gold Concentrator Sale

- Farm Equipment Price Philippines

- Proman Proman Mobil Jaw Crushers List

- Pumice Chimney Isokern

- Sandblast Equipment Manufacturers Information

- Quartz Miners In South Africa

- Birdsboro Buchanan Jaw Crusher Yugioh

- Jaw Crusher Beater

- Largest Crusher In Liberia

- Crusher 700 Tph Copper Mine Solves High Wear Area

- Dan Kekurangan Mesin Ball Mill

- Used Partable Rock Crusher

- Fluorite Ore Powder Machine

- Hot Sales High Efficiency Stone Crusher Rock Fine Crusher For Quarry