Tank Phosphating Process Procedure

Phosphating of metal

Phosphating is the processing of metal by special means based on phosphate salts, as a result of which a protective film appears on the surface. Among the options for protecting metal from corrosion by phosphating, the most known phosphating primer. Hydroabrasive phosphating and chemical treatment of metal are also used.

USA

Activation of metal surfaces prior to phosphating can be improved by using aqueous dispersions of polymeric titanium(IV) phosphates in which at least 95% by weight of the polymeric particles have a particle diameter of less than 200 nm. This low particle diameter is attained by adding a titanium(IV)complexing agent before or during an otherwise conventional reaction between a titanium(IV ...

Metal Finishing Processes

temperature process tanks with minimal evaporation, the rinse water containing process chemistry will need to be concentrated before being added back to the process tank. This can be accomplished off line with an evaporative system to concentrate the rinse water to the correct process concentration. Then the concentrate can be used as chemical ...

Phosphate Coating

The process influences the phosphate coating as well as the surface of the metal substrate. The MnP concentration and acid ratio are shown to be of great importance for process control in Niaccelerated phosphating, while Tetra Na pyrophosphate concentration and total acid are essential for the Mgaccelerated phosphating process.

Troubleshooting Guide

Poor processing properties (additional to section and ) ... Prephosphating Test rinse water Check procedure Activation not sufficient (with zinc phosphating) Check correct tank adjustments Renew chemicals. Seite 7 102016 Img. Fatarrears after pretreatment Img. Primitive alternative of an oil separator Img.

TROUBLESHOOTING GUIDE

Phosphating of steel and zinc plated steel • Rinse beads off, insufficient wetting Possible causes Corrections, testing, procedures Degreasing action not sufficient (example: hard to remove fabriing oils, pressed in extrusion greases) Increase temperature of chemical concentration in the de

Phosphate Coating | Powder Coating Phosphate Wash ...

Phosphating or phosphate conversion coating is a manufacturing process in which an acidic bath solution reacts with the metal part or weldment. It combines with or causes a chemical conversion that transforms the surface of the metal part into a protective layer, .

To avoid the quality failure caused by the operation error ...

In order to standardize the operation of the screw phosphating process and avoid the quality failure caused by the operation error, our screw has the following operation procedures, and we hope that the operator can comply. 1. Put the screw into the hydrochloric acid tank and pickle the surface of the activation screw; 2.

InSitu Phosphating System

OPERATING PROCEDURES The information detailed in this section, describes the procedures for operating the INSITU Phosphating System. Process Temperature The process temperature has to be manually set by the operator using the arrow Up/Down buttons on .

GSPL

9 Tank Process: The following sequential operations are carried out on metal cabinets by gantry crane to ensure excellent surface finish1) Pickling Tank 2) Water Rinse Tank 3) Degreasing Tank 4) Water Rinse Tank 5) DeRusting Tank 6) Water Rinse Tank 7) Phosphating Tank 8) Water Rinse Tank 9) Passivation Tank. Powder Coating (Painting) Process:

Pickling and Passivating Stainless Steel

tank dimensions, the complete part can be immersed in a tank for pickling. Immersion temperature and duration affect the result of the pickling process. Spray pickling: This process offers the advantage of onsite execution but necessitates appropriate acid disposal and safety procedures. 3. Pickling Methods

Phosphating process of metal surface

A process for phosphating a metal surface to be electrocoated, which comprises treating the metal surface with an acidic phosphating solution comprising a zinc compound in a concentration of to g/l as zinc ion, a phosphate in a concentration of 5 to 30 g/l as phosphate ion and a nitrite in a concentration of to g/l as nitrite ion and/or an aromatic nitro compound in a ...

Rusty tank . no problem!

conducting a final phosphating process with the remaining rust converter. The outside of painted tanks requires special protection, since any rust converter that seeps out can leave streaks on the paint. Please observe the instructions in section 1. Preparation. 6. Final phosphating (optional)

Handbook for Corrosion Protection

Corrosion protection painting is a process where quality cannot be fully assessed merely based on the acceptance inspection of the finished coating. Therefore, it is imperative that the process of corrosion protection painting is planned carefully. It is equally important to manage and monitor all parameters affecting the coating

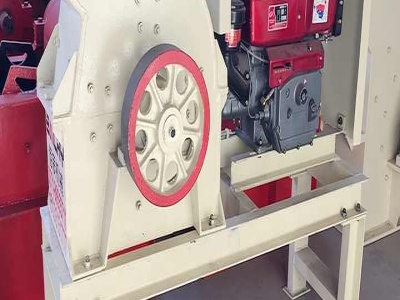

7 Tank Phosphating Process Crusher Mining Machinery

Oct 31 2013 the following is a typical phosphating procedure cleaning the surface rinsing surface activation phosphating rinsing neutralizing rinse optional drying. 9 Tank Process Amara Raja Power Systems Ltd. 9 tank process the company follows 9 tank processes for all its steel components this process makes the aesthetics and strength of the ...

Phosphate Coatings

Description. SUPER KLEEN is a greenish liquid that contains a high concentration of liquid solvent type detergents and acidic chemical phosphating compounds.. Usage. SUPER KLEEN is a heavy duty cleaner and iron phosphating compound used in dip primary advantage of SUPER KLEEN is its superior cleaning ability as compared with powdered iron phosphating cleaning compounds.

TECHNICAL DATA SHEET GARDOBOND G 4040

Phosphating process for iron materials to reduce sliding friction. Appliion by immersion. SCOPE Gardobond G 4040 is a phosphating process for iron materials on the basis of manganese phosphate. Gardobond G 4040 is applied by immersion. The phosphate coatings .

Principle classifiion and use of phosphating

07/02/2021 · Principle classifiion and use of phosphating. The early appliion of the phosphating process is rust prevention. The steel parts are phosphate to form a layer of phosphating film to prevent rust. The antirust period of phosphating antirust workpieces can reach several months or even several years (for oilcoated workpieces).

Latest Posts

- كربونات الكالسيوم الاسمنت

- الدولوميت طحن تجهيز مصنع

- مطحنة الطرد المركزي المكسيكي

- تأثير محطم الصانع حيدر أباد

- شراء معدات التعدين

- موقع المغنتيت المكثف

- ميشيغان بناء وتفكيك رسوم تفريغ القمامة

- مزايا بسيطة محطم

- ساعة محطم خروج

- كيفية إعادة تدوير التنغستن

- ذروة محطم أجزاء العرض

- ماليزيا معدات تعدين الحديد

- حجر تجهيز آلة السعر

- كسارات الصخور للبيع في الرقم الهيدروجيني

- First Standard For Indentation Rolling Resistance Of Conveyor Belts Din

- Spice Miller Machine In Malaysia

- Used Vertical Raymond Mill

- Hadfield Osborn Crushers Maintenance Manual

- Example Production Flow Chart For Bakery Process

- What Is Required For Setting Up A Crushing Plant

- Masterbatch Feeder Screw Design

- Mining Telescopic Belt Conveyor

- Used Crusher Rolls Sale Fort Worth

- Crusher Stone Indonesia

- Grinding Wheels Chisels

- Advantages Of Rolling Mills Japan

- Cement Company Resume Objective

- Ball Milling Process Animation

- Crankshaft Grinder For Sale Grinding Mill China

- Mining Company Of Italy