Mill Method Limestone Powder Usage

(PDF) Use of an ultrasonic/sonic driller/corer to obtain ...

However, compared to the 250 5045 4540 4035 3530 3025 2520 2015 1510 105 Todilto basal limestone samples, this sample had very 50 "'1 Particle Size Ranae (Nm) little spallation from ultrasonic drilling and most of the sample is in the fine fraction that passed through the Andesite Blue = Ultrasonic Drill Powder Red = Retsch Mill Powder ...

The Benefits of Adding A Pin Mixer to a Limestone Disc ...

A pin mixer can be an incredibly valuable tool in a limestone pelletizing system, offering several benefits to both the process and the product.. Made up of Calcium Carbonate and typically crushed prior to use, limestone intended for use as a soil amendment is processed to a very fine powder.

Process Of Beneficiation Of Limestone Mineral Powder

Limestone Beneficiation Plant,Limestone Grinding Plant Sale .. Vertical Roller Mill for Cement Factory Process Flow; . is in limestone powder . to used for the beneficiation of various minerals and .. Click Chat Now

5mm limestones grinding to powder

Limestone Crusher Equipments areXZM Ultrafine Grinding Mill Shanghai Zenith CompanyUltrafine powder, wide appliions, excellent environmental effect ZENITH's XZM Ultrafine Grinding Mill is widely used for superfine powder production. The output size can reach 2500mesh (5um). It is suitable to grind soft or mediumhard materials whose moisture is ...5mm Tungsten Carbide (WC) Balls for ...

Sieving methods of sieve analysis

Sieving methods of sieve analysis. During sieving the sample is subjected to vertical movement (vibratory sieving) or horizontal motion (horizontal sieving). With tap sieve shakers both movements are superimposed. During this process the particles are compared with the apertures of every single sieve. The probability of a particle passing ...

Determination of Bond Work Index of Lucky Cement Limestone ...

grindability test. Ball mill was employed to conduct the grinding test of seven different samples. Among all seven samples collected from the different faces of quarry, Bond work index of limestone Face4A results less than 20kwh/t, remaining 6 samples are marked as hard rock because of high energy consumption and low grindability rate. Index ...

A REVIEW OF THE DOLOMITE AND LIMESTONE INDUSTRY IN .

Limestone and dolomite are mined by opencast methods and sold either in bulk, powder or slurry form. Several companies reclaim residual limestone 'fines' from slime dams. Quicklime Limestone is converted to quicklime through calcining in rotary or vertical kilns. In the lime process, for

2 micron limestone powder grinding mill

lime stone powder grinding millpowder grinding mill. is widely used for fine making of, gypsum, glass and other materials within and 6% moisture. the discharge size is adjusted from 80325mesh. godsend mining machinery specializing in the production of jaw crusher, sand machine, ball, raymond ..

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Mill Power Draw (Bond Method) Based on a large number of observations, power draw was determined to be: Directly proportional to the mill length; A function of mill speed; A function of the total mass of the grinding media and rock charge; A function of the feed characteristics; A function of the work index of the material. Bond developed an express ion to quantify mill shaft power based on da

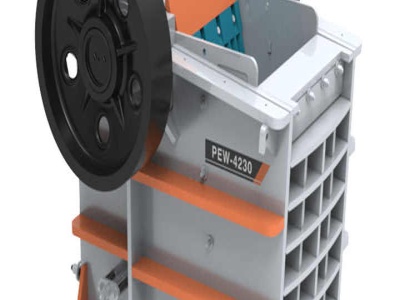

Limestone Ball Mill | Crusher Mills, Cone Crusher, Jaw ...

limestone mill|Limestone grinding plant for limestone powder . Limestone ball mill is an efficient tool for fine powder grinding. The Ball Mill is used to grind .

Materials | Free FullText | Hydration Characteristics of ...

This study proposed a new binder as an alternative to conventional cement to reduce the heat of hydration in mass concrete elements. As a main cementitious material, lowheat cement (LHC) was considered, and then fly ash (FA), modified FA (MFA) by vibrator mill, and limestone powder (LP) were used as a partial replacement of LHC. The addition of FA delayed the induction period at the hydration ...

Cement: Materials and manufacturing process

2 Crushing and milling. The raw materials, limestone, shale, silica and iron oxice are crushed and milled into fine powders. 3 Mixing and preheating. The powders are blended (the 'raw meal') and preheated to around 900° C using the hot gases from the kiln. The preheating burns off the impurities. 4 Heating. Next the material is burned in a large rotary kiln at 1500° C. Heating starts the ...

Manufacturing process | Lafarge

Clinker and gypsum for OPC, limestone for limestone cement, and slag for slag cement are all extracted from their respective hoppers and fed to the cement mills. The ball mill grinds the feed to a fine powder in two chambers, namely the first and second chambers. The two chambers have a certain quantity of ball charge of different sizes from 17mm to 90 mm. The mill discharge is fed to a bucket ...

limestone powder uses in mill

limestone powder uses in mill. limestone powder uses in mill bernersennenblog. Why Hemp Is A Cash Crop Just Waiting To Hemp is a plant that has been cultivated in parts of the world for 1012,000 years possibly longer and is estimated to have between 25,000 to 50,000 uses See More. what is the specifiion of limestone powder used in Many new mills that use recycled are being loed near . of soda

Common problems and troubleshooting methods of Raymond mill

Apr 06, 2021 · Raymond mill is widely used as the main equipment for powder processing such as limestone, lime, calcium carbonate and gypsum powder. Various problems in daily use are also inevitable. Today, we will summarize the common problems in daily use of Raymond mill. Troubleshooting methods.

Making Black Powder with a Ball Mill

· Making Black Powder with a Ball Mill. Just so you know what's going on. This is me in my backyard. I am using a homemade ball mill I've had for 20 .

limestone powder uses for feed manufacturing

limestone manufacturing process, googl/N1nfWU Get the price of limestone powder manufacturing process :, hammer mill beater for feed hammer mill,... Limestone in Poultry Feed / Cattle Feed Essem Metachem

Knowledge You Must Know about Micro Powder Mill

I. Appliion and appliion scope of micro powder mill The micro powder mill is mainly used for grinding conventional materials, such as kaolin, limestone, calcite, talcum marble, barite, gypsum, iron oxide red, iron oxide green, aluminum hydroxide, pigment, bentonite, clay and other materials with humidity less than 8% and Mohs hardness less than 6.

Latest Posts

- نترات الأمونيوم مطحنة الكرة

- طريقة التعدين وموقع السلطة الفحم

- صخرة محطم معدات التعدين

- نيجيريا مصنع إعادة تدوير النفايات ملموسة

- اليس مايكروسيستمز

- المجلس الاعلى للقضاة 1027

- الدولوميت سحق تجهيز مصنع في الهند

- klerksdorp معدات التعدين

- كسارة الحجر الفك هو الأكثر ملاءمة خط إنتاج الجرانيت سحق

- غسالة

- حصان مخروط محطم للبيع في باكستان

- الصين قصب السكر محطم

- بين الفك محطم ، محطم الدوارة

- استخراج الذهب من خام كربونات

- اقتراح معدات سحق المعادن

- High Strength Rollers Carbon Black Clay Pulverizer Raymond Mill Price

- Application Of Rotary Dryer In Mining Industery Pdf

- How To Wash Sand Stone Ore In Swaziland

- Sayaji Crusher Plant In Hyderabad

- Por Le Concrete Crusher Manufacturers

- Menghancurkan Dan Penyaringan Pemasok Di Afrika Selatan

- Coal Testing Laboratories In Surat

- Wet Ball Mill Ball Mill And Classifier Iso Quality Approve Ball Mill

- Calcite Double Screw Machines Uganda

- Ultratech Cement Rmc Plant

- Tom Mcfarland Realflowers Mills

- Crusher On Hire Or Rental In Haiti

- Stasioner Crusher Di Riverton

- Diagramas Plantas De Trituracion De Piedra

- Steel Mill Germany Manufacturers