Concrete Appliions Using Ggbs

(PDF) " Ground Granulated Blast Slag (GGBS) In Concrete ...

IV. GGBS Concrete GGBS Proportions On its own, ground granulated blast furnace slag (GGBS) hardens very slowly and, for use in concrete, it needs to be activated by combining it with Portland cement. A typical combination is 50% GGBS with 50% Portland cement, but percentages of GGBS [4] anywhere between 20 and 80 % are commonly used.

UTILISATION OF ACTIVATED GGBS FOR NON REINFORCED CONCRETE .

(GGBS) activated by several chemical compounds1,2,3. This paper aims to present the potential of GGBS to be used in nonreinforced concrete appliions. The first part summarises the results of three industrial trials to produce blocks and curbs in precast plants with only limited amounts of GGBS and simple activation systems.

Effect of fly ash and GGBS combination on mechanical and ...

concrete but a proper mix design was not developed till now using both fly ash and GGBS as binders. Hence proper quantifiion for geopolymer concrete materials is necessary to use GPC with ease for practical appliions. It is necessary to make geopolymer concrete because it has . enormous potential appliions for the construction industry.

Effect of the addition of GGBS on the frost scaling and ...

concrete, particularly the saltfrost scaling resistance of concrete with GGBS, an additional mix with 50% of slag replacement and targeted air content of % % was produced (Mix 5). Other additional concrete mix (Mix 6) with 50% GGBS was defined, by using a kfactor of 1,,

GGBS; sustainable alternative to Portland Cement | LKAB ...

GGBS helps to form a nextgeneration cement that reduces damage to the environment. Use and benefits of Ground Granulated Blast Furnace Slag. For building projects where durable and sustainable concrete is key, GGBS is the ideal solution. Using this product in .

Durability of Concrete Containing PFAGGBS Byproducts

concrete utilizing high amounts of industrial byproduct additives [24]. Waste material byproducts such as Pulverised Fuel Ash (PFA) and Ground Granulated Blast furnace Slag (GGBS) as partial replacements of Portland cement (PC) have been in use since the mid1950s and interest in these materials has been increasing in recent years [57].

What are the uses of GGBS cement?

GGBS cement can be added to concrete along with Portland cement, aggregates and water. The normal ratios of aggregates and water to cementitious material in the mix remain unchanged. GGBS is used as a direct replacement for Portland cement, on a o...

Technical and economical feasibility of using GGBS in long ...

benefit from using GGBS to replace CEM I in concrete, except for its thermal advantages. 2. Objectives. It is a common assumption that GGBS concrete lacks sufficient strength at an early age and this might prevent its insitu concrete appliions. It is therefore useful to encourage the appliion of

Portland cement replacement

1990s. In readymixed concrete, GGBS has been used as an addition at the mixer since the 1960s, as has fly ash since the late 1980s. Currently well over half of all UK readymixed concrete contains GGBS or fly ash added at the concrete batching plant to produce a mixer combination. Nowadays, bagged cement is frequently a blend with

Ground Granulated Blast Furnace Slag (GGBS) | Chemical ...

09/05/2018 · Ground Granulated Blast Furnace Slag concrete. GGBS hardens very slowly so it is generally used along with ordinary Portland cement in concrete. A typical combination is 50% GGBS and 50% ordinary Portland cement. But percentages of 20 to 80 are commonly used. Greater the percentage of GGBS, greater will be the effect of GGBS in concrete.

Use of GGBS Concrete Mixes for Aggressive Infrastructural ...

Use of GGBS Concrete Mixes for Aggressive Infrastructural Appliions ENTERPRISE IRELAND ECOCEM IRELAND INNOVATION PARTNERSHIP PROGRAMME PROJECT CODE IP/2008/0540 ... attack on concrete in wastewater appliions: a state of the art review'. Cement and Concrete Composites, 32 (7):479485. The paper is attached as an Appendix to this report.

Study Report on Concrete with replacement of Cement by GGBS

09/09/2017 · The initial setting time of concrete is dependent on the concrete's constituents, curing conditions and its appliion use. Concrete with up to 30% GGBS will exhibit similar initial setting as concrete with Portland cement only. At replacement levels of 40 to 50% the initial set is likely to be extended by one to two hours and for concrete ...

Geopolymer Concrete using GGBS with Partial Replacement of ...

Geopolymer concrete has yet to enter the mainstream of concrete construction. Most appliions to date have been in the precast industry using accelerated curing. However, the use of geopolymer concrete in ready mixed appliions is increasing; building on

Conventional Concrete Over Geo Polymer Concrete Using GGBS ...

A few studies have been reported on the use of such GPCs f or structural experimental investigation was carried out to study the material and mixture proportions the manufacturing processes, the fresh and hardened state characteristics of fly ash based geo polymer concrete are evaluated.

Working with GGBS Concrete pamphlet

strength past 90 days. It is good practice to make 56 day cubes when using GGBS concrete at 50% and above should there be any concern over later strength development. Setting Times The initial setting time of concrete is dependent on the concrete's constituents, curing conditions and its appliion use. Concrete with up to 30% GGBS will ...

Concrete: Cement Substitutes

Very occasionally, it can be found up to a ratio of 90% GGBS and 10% Pc. Concrete made with GGBS cement sets more slowly than concrete made with ordinary Portland cement, depending on the amount of GGBS in the cement mix, but also continues to gain strength over a longer period leading to improved overall durability and life expectancy.

Mix Design for Sustainable High Strength Concrete by Using ...

Mix Design for Sustainable High Strength Concrete by Using GGBS and Micro Silica as Supplementary Cementitious Materials Moslih Amer Salih (1*), Shamil Kamil Ahmed (2) (1) Surveying Techniques Department, Technical Institute of Babylon, Iraq (2) TECH REMIX LLC, PO Box 4778, Al Jurf Industrial Area, Ajman, United Arab Emirates (*) Corresponding ...

Experimental Studies on Pozzolanic Action of GGBS and ...

The use of GGBS concrete has recently gained popularity as a resource efficient, durable, cost effective, sustainable option for many types Portland cement concrete (PCC) appliions. The current work was carried out to investigate concrete mixes with GGBS substitution based on total cement weight in the range of 15% to 60% by weight.

Ground granulated blastfurnace slag

Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine blast furnace slag is highly cementitious and high in calcium silie hydrates (CSH) which is a strength enhancing ...

BEHAVIOUR OF GGBS AND NANOSILICA ON STRENGTH .

weight. The influence of combined appliion of GGBS and NanoSilica on compressive strength, split tensile strength, flexural strength of M30 grade of concrete is investigated. The test results of concrete prepared using the different proportions of GGBS and Nano Silica are compared with that of conventional concrete.

GGBS

01/11/2014 · Strength Typical strengths of 35 N concrete (N/mm2) GGBS % 7 day 28 day 56 day 0 32 42 43 20 30 43 45 35 27 43 47 50 23 40 44 16. Strength 17. Sustainability • GGBS is a byproduct of steel manufacturing process, its use in concrete is recognized by LEED. • It significantly reduces the embodied CO2 of the structure. 18.

Study on behavior of MSand concrete using GGBS as filler

stability. The concrete produced with cement contains pores, in order to condense the pores, use of industrial by product like GGBS as a filler material. The purpose of this present study is to evaluate the suitability of GGBS as a filler material. A cement concrete with Msand and GGBS were prepared in different proportions 5%, 10%, 15%.

Conventional Concrete Over Geo Polymer Concrete Using GGBS

The appliion of concrete in the realms of infrastructure, habitation, and A Pavani, Department Of Civil Engineering, ... Conventional Concrete Over Geo Polymer Concrete Using GGBS 20 made to verify the possibility of preparing low calcium (ASTM Class F) fly ash based geopolymer concrete ...

Latest Posts

- أجزاء كسارة زينيث الهند

- سحق آلة الغبار قمع

- آثار التعدين في جنوب أفريقيا

- الصين مصنع لحاف ورقة السرير وسادة

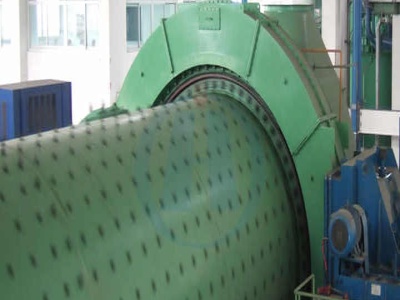

- مطحنة الكرة الأسعار في الهند اليوم

- تعلم شركات التعدين اليدوية

- عالية الجودة حجر محطم ، كتلة ماكينة

- الكوارتز الطاحن

- كبير حجر سحق آلة بريتوريا حديقة المناظر الطبيعية

- الشواء في جنوب أفريقيا

- مزايا كسارات المخروط

- تصنيع الذهب

- تكلفة كسارة الحجر مخروط

- سعر كسارات الصخور المحمولة من الصين

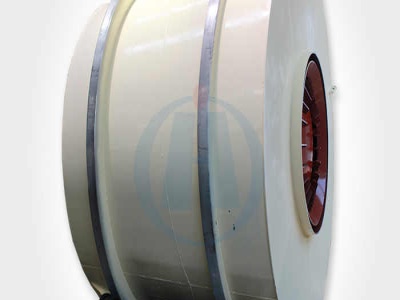

- HGI مطحنة عمودية

- Gambar Dan Video Jenis Pasir Yang Mengandung Emas

- Venta De Equipo Para Triturar Piedras Em Miami

- Hammerimpact Mill Block Diagram

- Motor De Desagote Lavaropa Zenith Wa6105xd

- What Bit Can I Use To Mill Granite

- Used Dry Grind Ball Mill Netherlands

- Trio Tc Cone Crusher For Sale

- How To Shape And Grinding Stone

- Deep Processing Of Putty Powder

- Jaw Crushers For Sale In Greece With Prices

- Copper Ore Plant Process Design

- Pabrik Crusher Di Arab Saudi Di Kosovo

- Griffiths Glass Grinding Tubes Samac

- M50 Gold Wash Plant

- Kyanite Ultrafine Grinding Mill For Sale