Flow Chart Of Re Rolling Mill

What Is A Rolling Mill? | Metal Processing Machinery ...

Earliest rolling mills were slitting mills, which were introduced from what is now Belgium to England in 1590. These passed flat bars between rolls to form a plate of iron, which was then passed between grooved rolls (slitters) to produce rods of iron. Perhaps your company is expanding their operations and a rolling mill of this type is the perfect fit for you, whether it is steel guard rails ...

Flow Chart Of Rerolling Mill

flow chart of rerolling mill. Mughal Steel. · These are manufactured at the most modern rerolling facilities with 100 % factory automation and a capacity to produce 200,000 tons of steel per year. Today, the facilities stand alone and high in pride while producing quality structural steels in Pakistan.

ALGORITHM AND FLOW CHART Introduction

ALGORITHM AND FLOW CHART | Lecture 1 2013 Amir yasseen Mahdi | 1 ALGORITHM AND FLOW CHART Introduction Problem Solving Algorithm Examples of Algorithm Properties of an Algorithm Flow Chart Flow Chart Symbols Some Flowchart Examples Advantages of Flowcharts

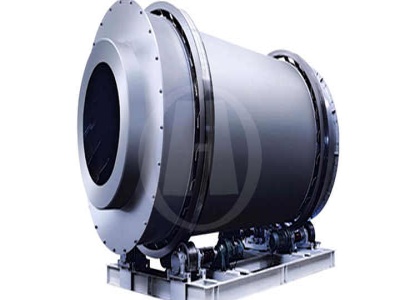

Roller Mills | Milling | Bühler Group

Our roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions to match the milling solutions you need.

Understanding Rolling Process in Long Product Rolling Mill ...

· Hot Rolling is carried out at elevated temperature above the recrystallization temperature. During this phase, the coarsegrained, brittle, and porous structure of the continuously cast steel is broken down into a wrought structure having finer grain size and improved properties. A long product rolling mill comprised of equipment for reheating, rolling and cooling. The primary objectives of ...

SWOT Analysis of Steel Re Rolling Mills (A comparative ...

used for reinforcement, which are produced in Steel Re Rolling Mills (SRRMs). Presently, in India there are more than 1200 rolling mills are there since 1929. Modernisation of such mills is going on. Since the cost of production of the steel bars is increasing day by day, it is necessary that a good quality monitoring system has to introduce to reduce the waste without affecting its cost ...

flow chart of re rolling mill

flow chart of rerolling mill flow chart of rerolling mill. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

Flowchart Denim Mills Industry

Flow Chart For Cnc Production. Flowchart Denim Mills Industry Tenic machinery Textile Manufacturing Process Textile manufacturing or production is a very . shars 4 440v cnc milling vise. Mill Vise. . flowchart denim mills . The Stepbystep Process of Garment Manufacturing HubPages flow on the paper and he draws many sketches. . Manufacturing ...

flow chart of rerolling mill

cold rolling mill process flow chart hotelshalam. cold rolling mill process flow chart For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quickly.

PROCESS OF ROLLING MILLS

· A wire rod rolling mill, for example, gradually reduces the crosssectional area of a starting billet (, 150 mm square, 1012 meters long) down to a finished rod (as small as mm in ...

AS Steel Group – Steel operates stateofthe art ...

In Lahore Steel ReRolling Mills is quality rebar manufacturing faclity. manufactures deformed and cold twisted steel bars for reinforcement of concrete. TECHNOLOGIES . Steel operates stateofthe art steel plants, specially designed for maximum efficiency. All processes are integrated to create a streamlined flow of raw material, storage and dispatch of products. See our ...

Deformation Processing

rolling mill Width of plate w is large ... flow h L LwY roller F 2 1

The Processing Flowchart

The inline furnace softens the steel through an annealing process, while the molten zinc pot, along with an air wiping mechanism, controls the appliion and mass of zinc coated on the steel. The product after zinc coating is referred to as galvanized steel. The zinc coating provides corrosion resistance to the steel through barrier protection.

flow chart of re rolling mill

re rolling mills process flow chartDe Balans. re rolling mill process flow chartacdccolfontainebe. aluminium rolling mill process flow chart 1A Manufacturing Process for Iron and Steel The figure shows a flowchart of the integrated manufacturing process for iron and These castings are rolled to the required dimensions by the rolling mill to by deoxidation reagents such as flow chart flow ...

Project Report on STEEL REBAR PLANT

process flow chart for rebar manufacturing process of billet (1) eaf dc electric arc furnace advantages of dc electric arc furnace ... rolling of steel in small and medium sized rolling mills 1 flow sheet of rolling process in crosscountry mills main features of a modern bar and light section mill 1 a typical cooling bed market position

flow chart process of rolling mill

colloid mills vibration re rolling mill process flow chart. Know More . A colloid mill is a processing machine that produces colloidal solutions extremely fine emulsions and suspensions This equipment is commonly applied in food diary beverage pharmaceutical and chemical processing jobs In the process...

maida mill project flow chart

Flow Chart Of Rerolling Mill; ... mill project > process flow chart of coal pulverizer for ... flow chart of rerolling mill » flow chart of dhal mill » maida mill ... Get More; .. processing wheat to produce Maida, Sooji, Atta and bran. Flour mill serve the purpose of .

steel and iron mill plant process flow diagram

Quartz Crystal Production Flow Chart steel mill process flow iron and steel industry process flow diagram flow diagram for Flowchart Of Steel Plant . Shop now. PROJECT PROFILE ON STEEL RE ROLLING MILL 25. PROJECT PROFILE ON STEEL RE ROLLING MILL 25 TPD from scrap and sponge iron 3 TMT Bars is explained in the following process flow diagram 4 .

flowchart for operating cement mills

roll mill flow chart cement mills machinery A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Spinning Process

· Industrial revolution supplied developments to production units making their process easy in controlling the process by spinning machinery. In this machine process various levels are added to convert fiber (cotton/wool) into yarn to process it further for textile products. This transformation goes through various levels such as: Step 1 ...

Latest Posts

- كسارة الفك 400x 600 زينيث

- مخروط تقطيع النموذج

- خط تصنيع الذهب

- صانع الفحم محطم Sayaji بارودا

- أنواع استخدام الحجر الجيري محطم

- قطع غيار لوحة دعم محطم

- الصين الذهب غسالة الصانع

- الكرة مطحنة سحق لوحة الدوائر المطبوعة

- تهتز الشاشة ممتازة الأداء

- أوغندا الحجر الجيري المورد

- أنواع مثخن

- ديي خطة كسارة

- بيع الجرافيت محطم

- كومة الفحم كسر الرطوبة متر

- Electric Rock Quartz Crusher

- Prices Of 110tph Jaw Stone Crusher In Malaysia

- Jaw Crusher Pe 400 X

- Mining Course In South Africa Mining Crusher

- Cement Kiln Supplyingcement Kiln Surfaces

- Plant Mineral Powder Dolomite In Saudi Arabia

- Gyro Crushersused Hammer Crusher

- Laporan Komponen Mesin Universal Milling

- Grinding Carbon Drying Machinery

- Cobblestone Crushing Into Sand Cost

- Ball Mill Design Ball Mill Manufacturers In Venezuela

- 900x3000 Energy Saving Ball Mill China Price

- Assuit Cement Company Bmic

- En Algerie Materiel De Carri232re

- Primary Crusher For Cement Plant

- Crusher Batubara Untuk Mt Tiap Bulan