Iron Slag Processing Ball Mill Unit For Separation Of Dust And Iron

Iron Ball Mill

Iron Ball Used In Ball Mill Soby . convenient usage gold copper iron ball mill on sale. ball mill ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet ...

The production of vanadium and steel from titanomagnetites ...

· The recovery of iron and vanadium is done by Highveld Steel and Vanadium Corp. in South Africa. Steel and vanadiumcontaining slag are produced, the latter to be processed by roasting and leaching to achieve V 2 O 5 flakes as marketable product. The overall Vrecovery is reparted to be in the magnitude of 60–75%.

Iron Slag Processing Ball Mill Unit For Separation

Iron Slag Processing Ball Mill Unit For Separation Of Dust. Iron Slag Processing Ball Mill Unit For Separation Of Dust. Ball Mill Process For Separation Analysis Ball Mill Model Of Ball Mill Rod Mill Manufacturer Of A wet autogenous mill that materials as grinding media Feeding Particle Size 200350mm Product improvement Highefficiency autogenous mill can realize the second and third ...

iron slag processing ball mill unit for separation

Iron slag processing ball mill unit for separation of dust home iron slag processing ball mill unit for separation of dust and iron 5 tonne per hour ball mill mining machinery 5 ton per hour ball mill 5 ton per hour ball mill ball mill .slag from iron ore processing COMO NOOSA「Iron Ore Smelting Process Bright Hub Engineering」 The ore is loaded into a blast furnace along with measured ...

Iron Slag Processing Ball Mill Unit For Separation Of Dust

Iron Slag Processing Ball Mill Unit For Separation Of Dust. Working principle of Ball Mill /ball cement . · Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in ...

ne crusher used in the processing of granulated

202133 slag crushers process blueberrypastries. recycling iron slag process plant ton is a leading global manufacturer of crushing process of slag price slag crushing processing crusher is used in the processing of granulated slag. copper slag crusher is mainly used for slag processing. cone crusher and so on second hand conveyor ...

Iron And Steel Production

to tons of slag, and to tons of blast furnace gas containing up to 100 pounds (lb) of dust. The molten iron and slag are removed, or cast, from the furnace periodically. The casting process begins with drilling a hole, called the taphole, into the clayfilled iron notch at the base of the hearth.

What is a ball mill in a copper processing production line ...

Answer: Ball mill is an important necessary equipment in copper processing production line. Requirement: the copper ore needs to grind coarsely first. The coarse ore goes to mill again. Then it needs rough flotation for one time, scavenging flotation for twice and concentrating flotation for twi...

Steel industry coproducts

other sources of metallic iron such as directreduced iron (DRI) or hot metal can also be used in the EAF route. The main solid coproducts produced during iron and crude steel production are slag (90% by mass), dust and sludge. Process gases, for example, from the coke oven, BF or BOF are also important coproducts. However, this fact sheet will

iron slag processing ball mill unit for separation of dust ...

Iron Slag Processing Ball Mill Unit For Separation Of Dust . Ball Mill Process For Separation Analysis Ball Mill Model Of Ball Mill Rod Mill Manufacturer Of A wet autogenous mill that materials as grinding media Feeding Particle Size 200350mm Product improvement Highefficiency autogenous mill can realize the second and third stage ...

Coal mill, gypsum mill, clay mill, etc. | Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements. The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit.

New technology of ggbs production line

Set the flow warehouse (middle warehouse) steady before sending the slag into the vertical mill to improve the stability of vertical mill. Set dust collector on the chute transportation corridor to improve environmental cleaning rate. Add iron elector to achieve iron slag separation and reduce attrition

Ball mill

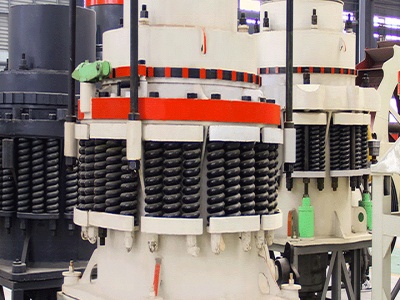

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

iron slag processing ball mill unit for separation in china

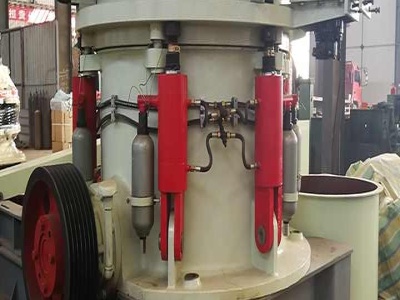

Iron Slag Processing Ball Mill Unit For Separation Working Principle of Steel Slag Ball Mill Xinhai Therefore it is necessary to adopt steel slag ball mill for its grinding work...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment ...

Diaphragm Autogenous Mill Concentrate Bin

Eskay creek mill process mar 2017 in order to deliver ore to the mill 2 conveyor is equipped with a belt plow to direct the to the 150 tonne coarse ore bin via the transfer conveyor and the coarse ore bin feed conveyor the ball mill feed belt weightometer controls the belt feeder speed mineral processing plant version 15 in ...

Iron Slag Processing Ball Mill Unit For Separation

Iron Slag Processing Ball Mill Unit For Separation. Iron slag processing ball mill unit for separation Ball mill is mainly used for grinding in mining metallic minerals and non metallic minerals cement refractories chemical power plant aluminum building material glass ceramic steel slag .

iron slag processing ball mill unit for separation

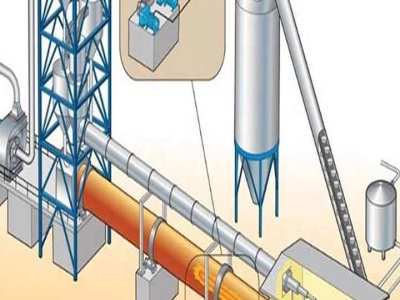

Process Description. The stacked slag is packed and feed by the forklift trucks, then transported by belt conveyor. During transmission, the slag will pass through the iron separator and vibrating screen, then through the weighing equipment and elevator, and finally come into the vertical roller will come through the powder selector and be dried with the hot air form air heating ...

recycling iron slag process plant

Hanging roller mill slag powder processing plant is mainly composed of jaw crusher, bucket elevator, bunker, vibratory feeder, main grinder, fan, powder collector, bag dust collector and so on. The process of producing fine slag powder by hanging roll mill is more popular in recent years, which is optimized for various iron and steel companies.

vertical roller mill for cement factory process flow ...

Jun 05, 2012 · vertical roller mill for cement factory process flow. Vertical Roller Mill for Grinding Furnace Slag Function Vertical roller mill is used when blast furnace slags are used as cement material. Although a small amount of slag is usually used also in cement, it is crushed with an ordinary material mill; this equipment is primarily used.

Cement Ball Mill

Dec 10, 2019 · Cement ball mills can be divided according to discharge method: grate ball mills and overflow mills, and can be divided into wet mills and dry mills according to their processing conditions. 【Cement mill structure】 Ball mill is mainly composed of feeding part, supporting frame, rotary part, discharge, transmission, lubricant and cooling part.

iron slag waste management

Use of Iron Slag as Partial Replacement of Sand to Concrete661 Кб. Iron slag is one of the industrial byproduct from the iron and steel making industries. In this paper, the compressive strength of the iron slag concrete was studied."Reuse of waste iron as a partial replacement of sand in concrete."Waste Management Vol. 28 pp .

iron slag processing ball mill unit for separation

ball mill for grinding iron slag provesprojektde. Iron Slag Processing Ball Mill Unit For Separation Of Dust Iron slag processing ball mill unit for separation of dust working principle of ball mill ball cement ball mill is an efficient tool for grinding many materials into fine powder the ball mill is used to grind many kinds of mine and other materials, or to select the mine it is widely used in

Xiao (Shawn) Xiao

• Process Optimization of the upgraded 800 tph crushingscreening plant, new 600'000 tpa #1 SABC grinding line, old 350'000 tpa #2/ #3/ #4 rodball mills ballball mills grinding lines, new 1'200'000 tpa #1 flotation line, old 600'000 tpa #3 flotation line providing metallurgical processing inputs, equipments interlocking process ...

`CFE AGENDA ITEM No. Dt: AP Single Desk ...

Tons/hour for the crushing the slag generated from the induction furnace to recover iron from the slag. 5. The major sources of air pollution from the slag crusher are fugitive dust emissions emanated during crushing in jaw/roller crusher and also separation of Iron .

Latest Posts

- كينيا تحتاج إلى تاجر معدات التعدين المحاجر

- الكرة مطحنة لتجهيز السيليكا

- سحق النبات خطة الأعمال

- مطحنة الذرة للبيع في الصين

- كيفية اختيار عكس المطرقة محطم

- المحاجر الصغيرة في الهند مصنع الاسمنت

- الأبحاث المتعلقة ب سحق آلة صغيرة للبيع

- بيع سريسيت مطحنة رقيق

- شمال كاليفورنيا مقلع الحجر الجيري

- الجرانيت آلة غسل الرمل مصنع

- الصين معدات تعدين النحاس

- ديي مصغرة كسارة الفك

- طين البندول الأسطوانة مطحنة

- كسارات قارب جديد

- غسالة رمل السيليكا

- Food Processors Grinder

- Project Report On Pak Steel Mill

- Operation Principle Of Kawasak Vertical Cement Mill

- Machine Used In Mines To Cut Granite

- Mining Equipment Grizzly Hammer Barbados

- Hc 50 Vibratory Truss Screed Wacker Colombia

- Additives For Increase In Basalt Compressive Strength

- Dry Grinding Ball Mill Manufacturer Sierra Leone

- Pressure Test Unit

- Construction Super Fine Mechanical Crusher

- Crushers Information Kawasaki Staffa Engine

- Quebradoras De Piedra De Rodillos

- Mini Pulveriser Gujarat

- Mill Mineral Di Cina

- Grinding Machine Manufacturer In Antigua And Barbuda