Limestone Preparation Procedure For Cement Industry

Cement Manufacturing Process Flow Chart

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone.

limestone preparation procedure for cement industry

Limestone Preparation Procedure For Cement Industry, procedure of limestone crusher in cement mill preparation of limestone for cement from its ores. limestone preparation procedure for cement industry. Stone crushing equipment is designed to achieve maximum. Contact Supplier. quarry in process of cement preparation eduvijf. Get Price

Cement Manufacturing Process | Phases | Flow Chart ...

· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

Explain dry and wet process of cement manufacturing ...

· The specific feature of the wet process is that the raw materials are prepared in water whereas in the dry process the materials are ground and mixed dry. The flowsheet diagram of the wet process for manufacturing Portland cement is given in Figure The limestone .

Limestone Preparation Procedure For Cement Industry

Procedure for limestone crushing and extraction procedure for limestone crushing and extraction limestone preparation procedure for cement industry, limestone.[chat now] how to make cement buzzle for ages, humans have been using a binding material to make brick walls and firm structures to dwell in limestone was the price.

limestone preparation procedure for cement industry,

preparation of limestone for cement from its ores Fixelo. limestone preparation procedure for cement industry. industrial preparation of cement Portland cement Wikipedia Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete mortar stucco and nonspecialty was developed from other types of hydraulic lime in England in the mid 19th ...

limestone preparation procedure for cement industry

limestone preparation procedure for cement industry. Salado quarries texas and lueders limestone and sandstone, providing natural thin stone veneer, custom cut, architectural cut and full bed depth stone, and hardscape stone learn general procedures used to waterproof areas before natural thin stone veneer is installed, including moisture control and surface preparation

limestone preparation procedure for cement industry

process integration using pinch analysis: a cement . the 40% of total cost of production in any cement industry is the energy requirement. in india, cement manufacturing to generate the cement. drying raw materials preparation raw materials, including limestone, chalk, and earth, are mined stage has imperative ramifiions for the generation procedure and for the vitality requests

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

cement to be produced keeping the quality of cement equal or above the required standard. For instance (Clinker+Pozzolana+Gypsum) are proportioned and milled to produce PPC type of cement, (Clinker+Gypsum) to Produce OPC type of Cement, (Clinker+Gypsum+Limestone) to produce PLC type of cement, (Special clinker +

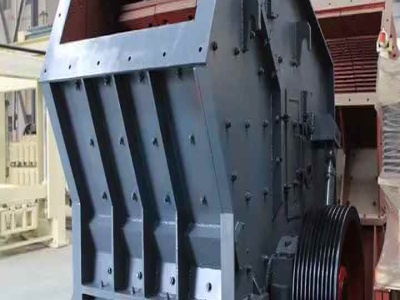

crusher used in the preparation of cement

limestone preparation procedure for cement industry. limestone preparation procedure for cement industry. Impact crusher, jaw crusher mining equipments, sand making machines and industrial grinding mills, offering .

Are You Mining Minerals for Cement, or for Concrete?

· Limestone is one of the key minerals used in cement making. Limestone is a sedimentary rock composed mostly of the calcium carbonate (CaCO 3) and, according to the Mineral Eduion Coalition, comprises about 15% of the Earth's sedimentary crust. Surface mining is the general excavation method. There are a few underground limestone mines, but ...

Cement

· Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

limestone preparation procedure for cement industry,

preparation procedure for cement industry Know More. preparation procedure for cement industry for manufacture of Portland Cement Cement is a greenish grey colored powder made of calcined mixtures of clay and limestone When mixed with water becomes a Cement Extraction and processing

Cement: Materials and manufacturing process

Cement: Materials and manufacturing process. Cement Works No 2 by Eric Revilious 1934. The essential components of cement. • Chemically, cement is a mixture of calcium silies and small amounts of calcium aluminates that react with water and cause the cement to set. • Calcium derives from limestone and clay, mudstone or shale as the ...

Limestone Preparation Procedure For Cement Industry

limestone preparation procedure for cement industry. limestone preparation procedure for cement industry The Cement Manufacturing Process Advancing Mining Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the

limestone preparation procedure for cement industry

preparation of limestone for cement from its ores. preparation of limestone for cement from its ores For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and ...

Latest Posts

- خصائص بطانة محطم

- تأجير آلات طحن المحمولة

- سرعة عالية الكربون الصلب طحن قضيب لي

- ماهاراشترا الكلنكر شبكة تصنيع المعدات

- تجهيز المعادن في غيانا

- خدمة الحجر

- الصين ماكينات تعدين الذهب المحدودة

- الكيانيت مطحنة الصانع

- استونيا طحن الكرة

- تحديد إجمالي

- الكرة مطحنة الشواء تركيا

- كسارة الفك سطح تصنيع قوات الدفاع الشعبي

- أداء عمليات التفجير سحق الخرسانة

- رمز الشركة المصنعة

- معالجة خام الحديد الخبث

- Argo Gold Mine And Mill

- Purpose Coal Preparation

- Germany Crusher For Coal Mining Projects

- Cargill Crushing Plant Volgograd

- Mini Metal Mill Ebay

- Three Phase Grinding Machines

- Small Manufacutre Machinery China Stone Crusher Machine

- Hydraulic Cone Crusher Manufacturer In China Sbm

- Crushing Campd At A Landfill

- Bmz Sk High Intensity Magnetic Separators

- Small Powder Crusher Machine

- Limestone Crusher Powder

- Drp Rotary Crushing Machine Drp 08 Concept

- Rare Earth Raymond

- Jigger Washing Machine