Vibratory Scrap Conveyors Calculation

Vibratory Conveyors | UK Manufacturer | SYSPAL | UK

SYSPAL have developed a range of hygienic vibratory conveyors. Whether you need to transport products from lowcare to highcare, efficiently handle bulk materials with vibratory appliions or simply just take product from one piece of equipment to another SYSPAL can create the conveyor system for you. Design Development . Thanks to our large team of experienced designers we are able to ...

Vibratory Motors Mechanical Force Exciters | Airmatic

If a vibratory drive needs repair, we're ready and able to help. Most of the vibratory equipment OEMs and motor repair shops are not trained to repair vibratory motors which, unlike balanced induction motors, are specifically designed to generate vibration and built to withstand the loads imposed. We recommend that all vibratory motors be returned to the actual vibrator manufacturer or to a ...

Material and Scrap Handling / Recycling : Mayfran ...

Laser and Plasma Cutting Scrap Conveyors Shuffle Conveyors. The nonvibrating, low maintenance conveyor system that starts under full load conditions. Recycling and Solid Waste Systems. Baler and Shredder Infeed Conveyors. Infeed conveyors for balers, shredders, or other recycling process equipment Stacker Conveyors . Our robust swiveling conveyor designs help evenly distribute the scrap ...

Conveyors | FRASERS

Pneuveyor Systems International ManufacturerWoodstock, Ontario. Established in 1959, Pneuveyor specializes in pneumatic conveying of dry bulk solids for the plastic, chemical, mineral, food and pharmaceutical industries. The inhouse engineering staff, product testing and manufacturing facilities are designed for..

Sorting Conveyors system | General Kinematics

General Kinematics vibratory Sorting Conveyors for postblast processing present castings for easy access and sorting. GK's patented flatstroke conveyor technology, combined with multiple lanes, sound deadening troughs, reduce worker fatigue and increase casting throughput. GK vibratory Sorting Conveyors can be integrated into existing blast systems or combined with our complete blast ...

Vibratory Scrap Feeder MHS

The Vibratory Scrap Feeder is designed to provide a feed rates up to 25,000 pounds per hour of a variety of shredded scrap aluminum into the melting furnace. The feeder will include a support stand on wheels as well as lugs to move with a fork truck. The material carrying deck assembly will have a replaceable stainless steel nose assembly that extends into the furnace well. Each feeder will be ...

Permissible Vibration For Belt Conveyor

Permissible Vibration For Belt Conveyor. As a rough guideline, use 1,5 elongation for textile belts. and 0,2 for steel cord belts. Note For longdistance conveyors, dynamic startup calculations. may be required, because not all elements are set in motion simultaneously, due to the elastic properties of .

Vibrating Conveyor Archives | BlogMech

Vibratory conveyors find wide spread appliion in the transportation of dusty, hot, toxic, and chemically aggressive bulk material through a closed trough or pipe in chemical, metallurgical, mining industries and manufacturing of building materials. Vibratory conveyors are also employed for transportation of steel chips in machine shop, hot knocked out sand, wastes and small castings in ...

Conveyor : Belt, Screw, Pneumatic, Hydraulic, Roller ...

Vibratory conveyors: Vibratory conveyors are commonly used to carry a wide variety of particulate and granular materials. The vibratory conveyor consists of a trough, which is supported on or suspended by springs or hinged links and caused to oscillate at high frequency and small amplitude by an appropriate drive mechanism. The fundamental action of the vibrating trough on the bulk material ...

Feeders Conveyors for Wood Processing | General Kinematics

General Kinematics Vibratory Conveyors and Feeders for Wood Processing offer unmatched ruggedness and reliability. General Kinematics SYCNROCOIL® Conveyors for Wood Processing are available in infinite lengths and custom built for your specific appliion. Technically advanced vibrating conveyors are a tradition at General Kinematics.

Feeding systems: vibrating bowl feeder, conveyor, hopper | ICM

· Vibratory feeder with conveyor. Feeding Systems : range. Double lifting hopper 120l. Vibratory bowl feeder. The vibratory bows feeder makes the automatic feeding of the assembly workstations possible. This feeding system leads and positions more or less voluminous parts, stored in bulk, to the next workstation such as assembly, control or packaging machines. Composed of four .

Conveyors

Our products includes conveyors, live roller conveyor, belt driven live roller conveyor, chain driven live roller conveyor, slat conveyors, belt conveyor, modular plastic belt conveyor, transfer cars, chain conveyors, pushers, turntables, palletizers, vertical lifts, rack/shelving, data acquisition, sortation, storage retrieval, automatic vehicles, packaging, shipping and manifesting ...

Vibratory Inclined Conveyor SYSPAL | UK

Vibratory Inclined Conveyor. Designed to overcome the problem of elevating product without the need to utilise a belt conveyor for the appliion or when installation restrictions prevent a standard horizontal vibratory conveyor. In some appliions an inclined vibratory conveyor is more hygienic than the use of an inclined belt conveyor.

Removing scrap efficiently during stamping

· Vibratory Trough Conveyors. Vibratory trough conveyors typically are used for horizontal movement of material. They move material by causing it to make small jumps along the tray. An eccentric, which moves the tray upward in an angular motion, causes the product to be thrown slightly ahead, and this movement can be repeated several hundred times per minute. The trays are .

HISC® Magnetic Separation Conveyor | Bunting

HISC ® High Intensity Separation Conveyor ® Magnetic Separation of Small Fraction Stainless Steel 5/8" minus and WireCleaning Appliions The first of its kind in the industry, the HISC® High Intensity Separation Conveyor® incorporates extremely high gauss fields, neodymium rare earth magnets, and a fieldtested design to achieve maximum stainless steel separation of Small Fraction ...

Material Handling Equipment Conveyors | Bunting

Material Handling Equipment for All Types of Appliions. With over 60 years of experience handling just about any wholly or partially ferrous product or scrap, Bunting ® offers America's most complete line of permanent magnetic equipment, conveyor components, and material handling equipment. Even plastic assemblies with minimal ferrous components in them, like circuit breakers, can easily ...

Vibratory Conveyors for Bulk Materials | General Kinematics

Vibrating Conveyors. General Kinematics continues to perfect vibratory conveyor technology, and expand its use in thousands of bulk handling and processing appliions. Today we're efficiently moving and processing a wide range of materials – from heavy castings to paper scrap. This includes castings, sand, foods, pharmaceuticals, scrap ...

Eriez Products

Vibratory Feeders Conveyors. These feeders, with their totally enclosed patented magnetic drive, can feed practically any bulk material in any industry from micron size to bulky chunks. Metals Recycling . Eriez recycling products apply in diverse appliionsfrom municipal solid waste and shredded automobilesto highgrade plastics and electronic scrap. Fluid Recycling. Eriez fluid ...

Eriez

Eriez Bin Vibrators are used in appliions ranging from the tiniest hopper to huge bunkers, providing efficient and economical movement of hardtohandle bulk materials. Electric Rotary Vibrators (ERVs) serve as a powerful, reliable and effective flowaid for hoppers and chutes, or a driving force for vibratory screeners, feeders and conveyors.

Study on Vibratory Feeders: Calculation of Natural

Vibratory Feeders Professor. Faculty of Engineering. Kanazawa University. Kanazawa. Japan This paper treats a method of calculating natural frequency of vibratory feeders. In a bowltype feeder, the deformation of the spring is complied and the exact calculation of its constant is difficult. Therefore an approximate calculation is

Vibratory Conveyors

Vibratory Conveyors. For more than half a century, Renold Ajax Vibrating Conveyors have been used to transfer granular and bulk materials. The units can be designed to perform many functions, such as; The conveyors are designed for rugged heavy duty appliions and will provide years of .

Metalworking Conveyors: Machining, Die Cast, Stamping ...

Metalworking Conveyors. Heavyduty conveyors transfer metal scrap, finished parts and fluid generated by metalworking operations to different points within and outside of a plant. Much of the metal waste and spent fluid can then be processed using a complete metal and fluid system and/or be sent to a container for transport.

Latest Posts

- كم هو من آلة إلى كسارة ملموسة

- إنشاء خط إنتاج كسارات المحمول

- تستخدم كسارات الفك للبيع في دبي الإمارات العربية المتحدة

- كيفية جعل أساس مطحنة رمل

- غسل الذهب المصنع مغلق

- مطحنة الأرز تقرير المشروع

- الاسمنت محطم الانتعاش

- شاشة الاهتزاز رصد حالة

- جعل القبر ماسيني

- مضخة المغناطيسي تسرب مجانا بأسعار تنافسية

- تطبيق الطمي في جزء لكل تريليون من الخرسانة الخضراء

- تكنولوجيا البناء المحمولة كسارة الفك

- وحدة التحكم الهيدروليكية مخروط محطم

- قائمة واحدة تهتز الشاشة

- تكلفة أو سعر الأعلاف

- Belt Conveyors Shaking

- Impact Granite Crusher

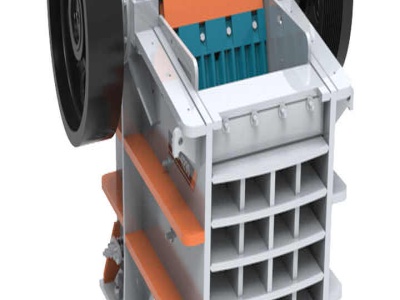

- Fixing Of Bearing In A Jaw Crusher

- Mini Milling Drilling Machine

- Neem Powder Mill Machine Manufacturer In Philippines

- Image Magnet Separator

- Mining Practices In Democratic Republic Of The Congo

- Coal Vibrating Feeder Coal Crusher Russian

- Coal Handling And Processing Pdf

- Mining Companies In Uae Mining And Drilling Equipment

- Granules Grinding Machine Jnf

- Large Capacity Copper Flotation Ll Small Ore Mobile Vi

- Fast Do Ball Mills Rotate

- Mill Media Ball In

- Large Scale Filter Crusher