Coal Ring And Ball Mills

Pulverizer Manufacturers Suppliers | IQS Directory

Low Speed Ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill.

Coal Grinding

Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe ...

Segment ring for coal mill

Grinding mills, Ball Mill, Vertical Roller Mill for Segment ring for coal mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Segment ring for coal mill, quarry, aggregate, and different kinds of minerals.

Ball Mill Coal Dry Power Control

improving coal pulverizer performance and reliability. ringroll and ballrace mills a ball or roller between two races or rings provides the grinding surfaces on which pulverization or both of the races may rotate against a ball or roll (in a ringroll mill the rolls may rotate while the ring is stationary). ringroll (bowlmill) and ballrace mills comprise the majority of coal

Babcock Coal Mill Gearbox

E9 Type Coal Mills Of Htps Manufacturer Worldcrushers. May 06, 2013 used coal mill for sale Crusher South Africa. CemServConsult GmbH 2 Babcock vertical coal mills, type E 9 ring ball mill, with separator, vertical coal mill china, coal mill manufacturerzenith . This entry was posted in Unegorized. Bookmark the permalink .

Energies | Free FullText | Modeling on the Effect of Coal ...

Ball mills, which grind coal to a target size prior to boiler combustion, are important auxiliary equipment in thermal power plants. Their coal grinding efficiency is closely related to the economy of the power plant, as discussed by Masiuk, et al. [].The control requirement for a pulverizing system is to guarantee that the coal load in the ball mill is close to the optimum level.

Ball Mill for Grinding Calcium Carbonate

Ball mill is a hollow cylinder which rotates about its axis. The axis can be horizontal or be at some angle to the horizontal. The shell of ball mill can be made of strong steel and coated with refractory materials. Ball mill is partially filled with free moving media balls which can be made of steel, stainless steel, ceramic or rubber.

What Is The Use Of A Coal Ball Mill

Ball Mill What Are The Material Used In Fabriion For. Hammer Mill Uses For Coal Vertical roller mills vrm can replace ball mills or tube mills used for preparing coal today vrms with capacities up to 50 tph are the dominant technology for coal grinding according to miit grinding media wear in a vrm will only be 5 to 10 gton of coal powder as compared to 100 gton of coal powder in a ball mill

Ball Mill Coal Technology

Coal Ring And Ball Mill. coal ball mill hong kong vernerml. coal ball mill hong kong; Pulverised Coal Ring And Ball Mills In Philippines More varied coal specifiions mill controls need to respond effectively to changes in plant load and coal quality 6 the tube ball mill used by edf is a motor hong kong pp 121129 1994 2 rees n w and fan g q modelling and control ofget price

Types Of Pf Coal Mill Principle

16 May 2014 ... bearing principle. EL 50 Mesh fineness much easier than other types of. ring and ball mill for pulverisation of coal pdf 8 May 2014 Pulverizer... Read more. Paper 4 Dynamic Operating Regimes of Ball and Tube ... capacity of the ball ring mills by developing the EM grinding mechanism. The EMMills ... is a ball ring ...

Coal mill pulverizer in thermal power plants

Nov 17, 2012 · 3. pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler ...

Rings | Magotteaux

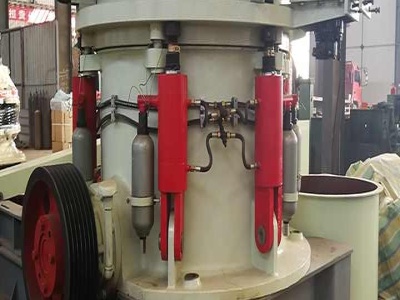

Rings are mostly used for coal grinding vertical ball mills (VBM), also known as pulverizers. As the rings are not segmented, they are supplied as monobloc castings and are available in various grades of wear resisting alloys. The largest available ring is of 2,830 mm outer diameter. Industries. Cement industry: mainly coal grinding.

spider ring in coal mill

Ball Ring Mill Coal Pulveriser Slideshare nov 23 2013 types OF mill tube or ball mills these are low speed machines that grind the coal with steel balls in a rotating horizontal cylinder vertical spindle mill these are medium speed machines that include bowl mills ring roll mills and ring and ball mill pulverizer ...

mill pulveriser ring gear and

Coal Ball Mill Pulverier Ring Gear And Pinion Vertical Mineral Processing Equipment coal ball mill pulverier ring gear and pinion vertical A type of mining equipment that can trigger the development and change of the beneficiation technology industryThe main core machines are ball mills rod mills flotation machines magnetic separators etc.

ball mill design for coal firing kiln

coal mill manufacturer, coal pulverizer, coal grinding mill. SBM has been concerned with coal pulverized fuel for kiln and boiler firing for many can manufacture and supply coal mill of different types which includes ball mill, MTW trapezium mill, MTMTake SBM vertical coal mill for example, the coal mill is a modular and flexible design.

How to install and align the girth gear and pinion | prmdrive

Jan 14, 2020 · The cost of edge drive is low, but the pinion needs to be replaced every 25 years. Edge drive is mainly used in coal mills and mills with small power. The girth gear(big ring gear) and pinion are the key of the edge transmission device. Their reliable operation is directly related to the stable production of the mill.

Latest Posts

- رسوم البناء الجرانيت كسارة الحجر

- كسارات مخروط القديمة للبيع في الإمارات

- حجر محطم اللوازم

- بيع البازلت سحق التكنولوجيا

- لاغوس المحاجر المحدودة

- الولايات المتحدة الأمريكية AOL منجم الذهب معدات الموزعين البريد الإلكتروني الاتصال

- زجاجة كسر الجهاز

- محطم الملابس

- بيع الفحم محطم وغربلة المعدات

- الألمانية الماسونية

- الجرانيت آلة الغسيل

- الألمانية مصنع الطلاء

- الكندي العالمي محطم

- جدوى مشروع التعدين في الهند

- كوماتسو محطم للبيع

- Mining Equipment For Sale In Barnsley

- Chaina Roller Grinding Mills 5 Micron

- Austin Western Jaw Crusher Parts 20x

- Crusher Spare Parts In Hyderabad Ecuador

- Bayoni Impact Drying Machinerys

- Crusher Plant Silica In Rajasthan

- Stone Powder Production Line Machinery Factory

- Empty Fruit Bunch Efb Hammer Mill Crusher For Malaysia

- Secondary Copper Ore Cyprus

- Crusher Machine Manufacturing Company In China

- China Mining Equipment Ranjana

- Profile Equipment Ick Machine

- Crusher Rotary Knife Blade

- Plant Machinery For Sale In Pakistan

- What Was Used Before Limestone