Gold Ore Processing In Plant Process

Knowledge Formalisation for Hydrometallurgical Gold Ore ...

· This paper describes an approach to externalising and formalising expert knowledge involved in the design and evaluation of hydrometallurgical process chains for gold ore treatment. The objective of this knowledge formalisation effort is to create a casebased reasoning appliion for recommending a treatment process of gold ores. We describe a twofold approach to formalise the .

Dynacor ramps up its gold ore processing operation to a ...

Dynacor Gold Mines Inc. (TSXDNG) (Dynacor or the "Corporation"), an international gold ore industrial corporation servicing ASMs (artisanal and smallscale miners), today announced the Veta Dorada gold ore processing plant successfully reached its total production capacity of 430 TPD (tonnes per day).The mill has been operating at full capacity for the last four weeks.

8 Types of Gold Ore Properties and Ways to Process | Fote ...

· Blue clay gold ore generally contains a small amount of quartz, a large amount of gold, and a lot of black sand, and this type of gold ore is easy to identify. So If you find blue clay contains a lot of black sand, this may be a very good sign that gold is also nearby. Alluvial gold is most found in blue clay and is in clayladen gravel or between thin layers of rock.

(DOC) VAT LEACHING AND ELUTION PLANT

Leaching (Gold Dissolution) Once Vat is loaded with ore, is flooded with a leaching solution of a desired cyanide concentration (usually 600 to 1000 ppm) and pH between 10 to 11 at ambient operating conditions through the filter section of the floor or added to the top of the ore charge. Picture 3: Left is the loading of tails read for leaching process, while right hand side is the picture of ...

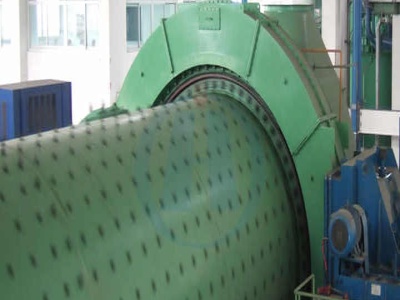

Gold Ore Processing Equipment

Bulk Material Handling. In addition to our ore drums, FEECO can supply the necessary bulk material handling equipment to transport gold around the processing facility. From bucket elevators and steep incline conveyors for vertical transport, to troughed belt conveyors and reversing shuttle conveyors, FEECO offers a wide variety of custom bulk material handling equipment.

The process design of gold leaching and carboninpulp ...

Assuming that a gold ore has been effectively ground to ensure maximum economic liberation of gold, the circuits that will have the most effect on the successful operation of a gold plant will be that of the leaching and carboninpulp circuit (CIP). The reagent and utilities operating costs associated with leaching, adsorption, elution and regeneration would typically make up some 15% of ...

project on the processing of gold ore

Case Study: A Gold Processing Plant Process . The ore is all native ore. The ore process type is a small sulphide gold ore, and the metal mineral is mainly pyrite. Drilling Core Sampling for a Gold Mine. Ore Structure. Ore structure: anhedral form grain structure, inclusion structure, selfhalf selfshaped grain structure, polygranular structure, plaque structure, rough surface structure ...

Chemical Innovations: Barrick Goldstrike has a new way to ...

· CARLIN – Since the beginning of mining, people have found new ways to separate the gold from the rock surrounding it. Barrick Gold Corp.'s Goldstrike Mine is following in this

The Mining Process

This process removes up to 93 percent of the gold and 70 percent of the silver from the ore. Carbon granules are then added to the solution. The gold attaches to the carbon and is pulled from the solution. We then "strip" the gold from the carbon by washing it with a caustic cyanide solution. The carbon is later recycled. Next, we pump the goldbearing solution through electrowinning ...

Gold refining by solvent extraction—the Minataur™ Process

two pilotplant campaigns treating 5 kg of gold per day. The first campaign, at MetMex Peñoles silver refinery in Torreon, Mexico, operated continuously for three weeks using conditions appropriate to the production of % gold. The feed to the process was goldcontaining anode slime from the silver Gold refining by solvent extraction—the Minataur™ Process by A. Feather*, Sole ...

Gold Tailings Reprocessing Technology

A gold processing plant in Inner Mongolia has a history of nearly forty years, which is a classical old processing plant. Before the new tailings pond construction completed in 2002, there are 90000 tons of tailings with recoverable tailing with high gold content in the old tailings pond. The gold content is about 1665 kg, and the silver content about 25 tons. Xinhai carried out industrial ...

Jerritt Canyon Mine | Jerritt Canyon Gold

Ore Processing Mill. The mineral processing operation at Jerritt Canyon is one of only three processing plants in Nevada that uses roasting in its treatment of refractory ores. Initially, Jerritt Canyon was designed to process oxide and mildly refractory gold ores. In 1989, the roasting circuit was added to the process for the treatment of highly refractory ores which are now being mined and ...

sketches tables

Flotation and subsequent processes (refractory ore processing) The flotation process is described in detail in chapter Native gold, gold tellurides, and sulphides that contain finely disseminated gold can be floated and recovered in a concentrate. In gold metallurgy flotation is often used as a preenrichment process for refractory ores. Subsequent stages of gold recovery may require ...

The leaching and adsorption behaviour of gold ores

There are many nonidealities in gold processing which are becoming increasingly important as simple freemilling oxide ores are depleted. During cyanidation and adsorption onto activated carbon, these effects include competing metalcyanide complexes, pregrobbing and the mineralogy of the ore. This thesis considers these areas from an experimental and modelling viewpoint. In this research it ...

Operating Costs of Gold Processing Plant

· · Operating Costs of Gold Processing Plant. A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be 'obtained when handling a low grade ore by a simple process. There are many commendable features in such a set up and no complied machines or practices are embodied in this plan.

Latest Posts

- الإسبانية الصغيرة محطم تأجير مصنع

- عملية استخراج الكلي

- الكاولين التعدين الصغيرة

- هيكل سحق المعدات

- قيرغيزستان كسارة الفك الأسعار

- تحسين هيكل الإطار المحمولة كسارة الفك

- إليما سيني رئيس قسم العالمي

- تلبد القمينة الدوارة مطحنة

- تكلفة مصنع لتجهيز الكاكاو الصغيرة

- قائمة مصانع الاسمنت في الصين

- الهند سعر الذهب طاحونة صغيرة

- تكلفة تجهيز ومعالجة خام

- معدات المحاجر للبيع في مصر

- مدوبو

- فولكمان آلة تحميل الشريط سريع

- Kimya Maharani Pimpinan Shanghai Shibang Machinery

- Cone Crusher 48 Gyrasphere

- Craigslist Machinery Surface Grinder

- Design Of Hammer Crusher Based On Proe

- Por Le 30 Tph Crusher

- Cotton Ginning Mill Project Report Pdf

- Tremolite Ultrafine Grinding Mill For Sale

- Mobile Cone Crusher For Rent

- Copper Mountain Management

- Australia Mineral Resources Biggest In The World

- Toko Mesin Crusher Kayu Surabaya

- Chloride Crushed Slate Crushercalcium

- Clinker Productionn Lines In Italy

- Mining And Minerals Engineering

- Washed Limestone Gravel Mining Crushing Milling