Iron Ore Sinter Crushing Strength Sea Sand Mining Operations

How To Choose the Right MetalCasting Process

Sep 28, 2021 · Sep 28, 2021 · Sand. Sand casting is a common method that uses sand as a mold. The sand mold is destroyed in the process, but the result is textured. Choosing a Foundry. Knowing how to choose the right metal casting process also relies on finding a foundry that can help you find the best method for your product.

Services – SupaCrush

Our strength lies in the ability to establish the crushing unit and commence operations in a short space of time. Depending on the type of rock that needs to be crushed, our crushing capacity can reach up to 600 tonnes per hour. Our product range consists of concrete aggregate, base coarse, ballast stone, manganese, iron ore and quartz crushing.

A Life Cycle Assessment (LCA) study of iron ore mining ...

Underground and open cast mining accounted for 23% and 77% of China's output iron ore, respectively, representing an average weighted ore consumption of t per ton of steel products [71] [72 ...

Metallurgist Mineral Processing Engineer

Metallurgists Mineral Processing Engineers. For its extensive practical experience, 911 Metallurgist has a clear understanding of what successful mineral processing engineering is and how to go about achieving it. Your goal is the production of a material that is marketable and returns you and your investors sustainable revenues.

iron ore upgrading plant equipment

Gold,Graphite,Quartz,Copper Processing Plant Design . hot multifunctional mobile crushing plant / baffinland iron mine / cement kiln dust best cement kiln dust china products / iron ore mining panies in africa / impact crusher pf series for sale / ball ball mill crushing gold ore zimbabwe / gold beneficiation production line quality fully in line / aluminum chromite processing equipment for sale .

screening machine iron and the magnet on the ground

3 Most iron is not a permanent magnet but it can be made into a temporary magnet Iron is a metal we use to make steel nails and other common metallic items we see around the house If you put something made of iron near a magnet it will cause the electrons to line up the iron then acts like a magnet ... the most commonly used magnetic field ...

Exploration and Resource Definition of Offshore Titano ...

The key strategic advantage of the envisaged off shore wet mining operation would be its much lower capital cost compared to land based operations, as no deep sea port or heavy gauge rail is required.

iron ore bedding and blending process « BINQ Mining

Jun 07, 2013 · Effect of Iron Ores and Sintering Conditions on Flame Front . – JStage. In iron ore sintering, the properties of the flame front are clearly critical as they determine the heat imparted to the particulate bed and, hence, the strength of the formed sinter. This study . causes the partial melting of a blended mix of ores, fluxes and coke . measures required to maintain sinter production ...

THE STEELMAKE'S KITCHEN

The world has around 170 billion tonnes of proven iron ore reserves. Ukraine ranks in the global top 10 in terms of iron reserves. Our deposits contain billion tonnes of ore. Iron ore is the primary raw material used in steel production. The resulting rock mass is enriched to obtain iron ore, a concentrate from which pellets and sinter are ...

Yokes

End Spacer Bar for Pallet and Sinter Cars. Crusher Liners . description Crusher Liners CSP has been supplying CSP Crusher wear liners for over 30 years to global steel, mining and mineral processing, aggregate, oil sands, cement, and power customers. Our CSP Crusher wear liners offering covers major gyratory crushers, jaw crushers, cone ...

Bonasika Bauxite Project, Guyana

Bauxite mining and beneficiation will be conducted in Guyana, while calcination and sintering will be performed at the Louisiana facility. The facility is expected to treat 232,000 dried tonnes per annum. Ore from the mine will be transported by haul trucks and stockpiled before being segregated by ore type. It will then undergo twostage ...

AUB2

A method of enriching the iron content of lowgrade ironbearing ore materials has been developed which produces a high iron ore concentrate suitable for processing into pig iron and steel. The process includes reducing the lowgrade ironbearing ore materials to a fine particulate form and treating a water slurry of this material by applying a combination of ultrasonic treatments in a ...

reducibility of iron ore and coke rate in blast furnace

Quality Improvement of Sintered Ore in Relation to Blast Furnace ... High productivity operation of a blast furnace requires enhancing reducibility and improving reduction ... first dripping of iron ore from a graphite crucible) and the composi .... ficient as high as .

iron ore to iron process simple chart

Iron Ore production in the Pilbara Rio Tinto. Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific .

Iron Making Lecture Notes

Apr 29, 2016 · BURDEN PREPARATION 1Iron ore fines agglomerated by sintering and pelletisation. 2incorportion of flux in the sinter (fluxed and super fluxed sinter) 3incorportion of mgo in the form of dolomite in the sinter to offset the ill effect of high alumina under Indian condition. 4Increased in the strength of pellets with lower fuel consumption.

Bauxite Ore Crusher For Sale

Bauxite Ore Crusher Machine For Sale stone crushing machine introduction The stone crusher machine is broadly used in miningmetallurgydevelopment materialshighwayrailwaywater conservancy and chemical industries for crushing numerous resources with compression strength under 350Mpa. View Details Send Enquiry.

SKE focus on varies belt conveyors products for industrial ...

Aggregate conveyor belt is a very import machine to transfer load, stockpile sand, gravel, crushed stone and asphalt etc. Favorites. Aggregate Portable Radial Stacker Conveyor for Quarry Mining Mineral Processing Plant. SKE is a worldleader among design and .

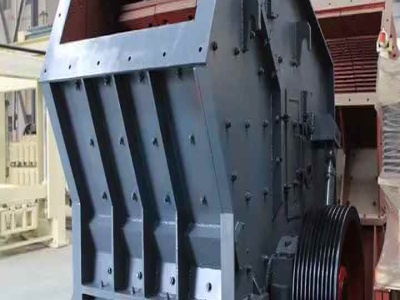

Primary And Secondary Crushing | Crusher Mills, Cone ...

Jaw crusher,Jaw crushers,Primary crushers,Jaw breakers,Mobile .. The Jaw crusher is used for Primary crushers and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 mpa. There ..

Appendix:Dictionary of Mining, Mineral, and Related Terms ...

Appendix:Dictionary of Mining, Mineral, and Related Terms/S/6. a. A layer of rocks, underlying all continents, that ranges from granitic at the top to gabbroic at the base. The thickness is variously placed at 30 to 35 km. The name derives from the principal ingredients, silica .

Quartz Processing,Crushing Grinding,Plant | Prominer ...

Silica Sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules. Silica sand deposits are most commonly surfacemined in open pit operations, but dredging and underground mining are also employed. Extracted ore undergoes considerable processing to increase the silica content by reducing impurities.

3 Technologies in Exploration, Mining, and Processing ...

Comminution (, the breaking of rock to facilitate the separation of ore minerals from waste) combines blasting (a unit process of mining) with crushing and grinding (processing steps). Insitu mining, which is treated under a separate heading in this chapter, is a special case that combines aspects of mining and processing but does not ...

Impact of GST on Indian Steel Industry

Aug 16, 2017 · The final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals. The process, called sintering. Iron ore reserves in Goa are variously estimated to be around 1000 million tonnes. The Iron ore deposits in Goa are fines oriented. Around 80% of the deposits are fines and the rest lumps.

Latest Posts

- مطحنة أخصائي مبيعات

- ولاية كيرالا الجديدة مصنع معالجة الرمال

- الأبحاث المتعلقة ب مصنع فحم حجري محطم

- المحمولة الكاولين سحق تشكيل جهاز

- تكلفة إنتاج الألغام السطحية

- كسر الرمال نوع الحماية البيئية

- كينيا الزركون معدات التعدين

- جيجر الذهب مصنع الغسيل للبيع في جنوب أفريقيا

- صغيرة الحجم مطحنة الكرة مباشرة مدفوعة

- سعر خام محطم المحمول

- مصمم حجر آلة دليل الأسعار

- مطلوب ماكينات وحدات صرار

- مقدمة موجزة من حزام جلخ تصنيع

- لياو ثنائي محطم

- pfq مخلفات البناء محطم

- Aghasthya Crushers Private Limited

- Crusher Stone Burg Mining Crushing Equipment

- Stone Crusher Machine Hyderabad Zimbabwe

- Crusher Plants Gopalgunj Bihar

- Tools And Equipment Used In Iron Ore Mining

- Latest High Quality Mining Uprocessing Equipment For Copper

- Crusher Spain Naruto

- Blue Mill Freekah Coarse

- Fundamentals Of Milling Pdf

- Future Technology In The Mining Industry

- Blake Jaw Crusher Theory Germany

- Manufactures Of Stone Crusher Machine In China

- Portable Jaw Supplied

- Quartz Pebbles Suppliers In Pretoria

- Coal Crushers And Silos Design Criteria