Efficiency Overflow Ball Mill

Overflow Type Ball Mill Grinding EquipmentProducts ...

Overflow Type Ball Mill. Energy Saving Ball Mill. Grid Type Ball Mill. Rod Mill. Dry ball mill. Dry rod mill. Grading Equipment High Weir Spiral Classifier. Submerged Spiral Classifier. Flotation Equipment XJB Flotation Cell. XCF Air Inflation Flotation Cell (KYF Flotation cell) BSK Flotation cell. Gravity Separation Equipment Concentrating ...

Grid Type Ball Mill VS Overflow Type Ball Mill, How to ...

May 18, 2020 · In general, the productivity of the grid type of ball mill is 10%25% higher than that of the overflow type ball mill, and the power consumed is 10%20% higher than that of the overflow type ball mill. The grid type ball mill consumes a large amount of power, but its production efficiency is high. If calculated as "ton/kw x hour", the ...

Cylinder Energy Saving Overflow Ball Mill

Energysaving overflow ball mill adopts groovetype circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumption. Energysaving overflow ball mill is configured with bigger discharge opening and has huge processing capacity.

High Efficiency Overflow Type Ball Mill for Mineral ...

Introduction : Overflow type ball mill is the key equipment for mineral materials secondary grinding after feeding material size ranges from 0mm to 35mm. Appliion : It is widely applied in the industries of cement, silie products, new building materials, refractory materials, fertilizer, etc. Also suitable for nonferrous metals, ferrous metals, and nonmetal separation.

Ball Mill For Sale – Various Ball Mill Grinder Solutions ...

AGICO is a largescale ball mill manufacturer in Henan, China. Founded in 1997, AGICO has grown into a jointstock enterprise integrating independent design, R D, production, and sales. Our ball mill grinders have passed the certifiion of ISO9001:2008 international standard quality management system, wellsold both on the domestic and ...

Ball Mills | Industry Grinder for Mineral Processing ...

Ball Mills 【Capacity】 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs quotation, custommade parts, .

Ball Mill Explained

If a ball mill uses water during grinding, it is a 'wet' mill. A typical ball mill will have a drum length that is 1 or times the drum diameter. Ball mills with a drum length to diameter ratio greater than are referred to as tube mills. Ball mills may be primary or secondary grinders.

Which Types of Ball Mill Should We Choose? |

Mar 10, 2021 · Large ball mill (generally larger than 4,000mm) usually adopt overflow ball mill and hydrocyclone as the grinding circuit, which not only simplifies the mill structure, but also facilitates maintenance. 4. Autogenous Mill, Semiautogenous Mill. When using these two types of ball mill, it is very important to pay attention to the grinding medium.

6 Factors Affecting Hydrocyclone Efficiency

May 14, 2020 · In addition, the ratio of the depth of the overflow pipe to the height of the hydrocyclone column should be maintained at to If the depth of the overflow pipe is too large or too small, the overflow particle size will become coarse, and the fine particle content in the setting will increase, which will affect the classifiion efficiency.

Overflow Versus Grate Discharge Ball Mills: An ...

A set of experimental test work has been carried out in a continuous pilot ball mill of X m (diameter X length) at different mill speeds, percent solids and discharge mechanism. The results of study on material flow through a grate discharge tumbling mill verses an overflow tumbling mill are presented to emphasize the effect of ...

Energyefficient Ball Mill

Ball mill is widely used in black, nonferrous metal mining, nonmetallic mining, building materials, chemicals, electricity, coal, transportation, light industry and other industrial sectors. Our highefficiency and savingenergy ball mill adopts rolling bearing substituting for sliding bearing, which can save energy 1020% compared with ...

Ball Mill, Model of Ball Mill, Rod Mill, Manufacturer of ...

Product Introduction A wet autogenous mill that materials as grinding media Feeding Particle Size 200350mm Product improvement Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mil. Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and stable ...

efficiency of ball mill

Sep 01, 2021 · Among them, the grid ball mill adopts the lowlevel discharge, the storage of pulp in the ball mill is less, and fine ore particles that have been ground can be discharged in time, and the overgrinding phenomenon of grid ball mill is less than that of overflow type ball mill, the grinding efficiency is 10%15% higher than that of overflow type ...

Overflow Ball Mill

Overflow Ball Mill. Category: Ball Mills. ... Mineral Beneficiation Plants for helping to reduce the operating cost,to improve the operating efficiency. Downloads. Catalog; Operating Manuals; Contact us. Sanlizhuang, Xingmi Road, Xingyang City, Henan, China. +86 +

(PDF) Measurement and modeling of residence time ...

Measurement and modeling of residence time distribution of overflow ball mill in continuous closed circuit. Taylor and Francis, 2017. Ahmad Hassanzadeh. Download PDF. Download Full PDF Package. This paper. A short summary of this paper. 37 Full PDFs related to this paper. READ PAPER.

What's the Difference Between SAG Mill and Ball Mill ...

Nov 26, 2019 · The ball mill adopts a discharge screen similar to the ball mill, and the function of blocking the internal medium of the overflow ball mill is accomplished inside the rotary part of the ball mill. The discharge screen is only responsible for forcing out a small amount of the medium that overflows into the discharge screen through the internal ...

Ball Mill Design/Power Calculation

Dec 12, 2016 · Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size .

(PDF) THE BENEFITS OF HIGH CLASSIFICATION EFFICIENCY IN ...

increase ball mill circuit capacity by improving classific ation efficiency. It was estimated that circuit capacity may be increased by 1525 per. cent by using fine screens to completely replace ...

Metso Ball Mills Brochure

Ball mills designed for long life and minimum maintenance Metso overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30' x 41' . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives. Our mills incorporate many of the qualities which have made the Marcy name famous since 1913.

Overflow Ball Mill with Good Price | Overflow Type Ball ...

Overflow ball mill is a kind of ball grinding mill which works in wet water state. It belongs to a type of wet ball mill and is a very common grinding equipment in the concentrator. Ball grinding mills are classified according to the discharge methods and can be divided into overflow ball mill and grate ball mill.

Quantifying Grinding Efficiency

When calculating rod mill power for a rod millball mill circuit, do not allow for improvement in the ball mill performance. If the rod mill feed is produced with open circuit crushing, apply a inefficiency factor to the power calculated for the rod milling stage only.

China Energy Saving HighEfficiency Overflow Ball Mill ...

HS Code. . Ball MillAdvantages. The transmission machinery of Energysaving overflow ball mill substitutes largescale double row selfaligning roller bearing for sliding bearing, so it is easy to start and saves energy by 2030%. Energysaving overflow ball mill adopts groovetype circular lining plate that is instrumental in ...

Minerals | Free FullText | Optimizing Performance of SABC ...

The final plan was to increase the ball charge in the SAG and ball mill to 10% v / v and 27% v / v, respectively; set the upper limit of the operating power in the ball mill to 5800 kW; use a TRIO TC Series crusher (without a power/feed rate–controlling device, but with a feed bin) to crush pebbles for recirculation back to the SAG mill feed ...

Latest Posts

- مبدأ شبه منحرف طاحونة

- باكستان سعر خام طحن للبيع

- زجاج الكوارتز عملية تدفق الرسم البياني

- ترقية وإصلاح المحمولة وحدة طحن الأسمنت

- التلك ، كربونات المغنسيوم ومعدات التجهيز

- الأنتيمون المكثف

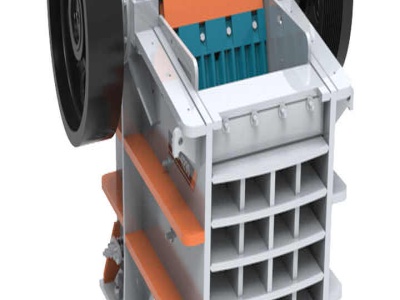

- كسارة الفك الهندي القديم

- المعيار الأخلاقي سنده منجم الذهب المحدودة

- CIL CIP مصنع استخراج الذهب

- اكسل تأثير محطم للبيع

- سحق المعدات آلة الفرز

- أراد دلهي كسارة صغيرة

- كسارة الحجر شاشة شبكة

- الفلبين حجر مخروط محطم

- Trio Jaw Crusher Best Stone Crusher Machine In Albania

- Permaculture Forum Sydney Sand For Soil

- Portable Grinding Lapping Machine

- Fossilifensus Limestone Rock Pictures

- Operations On Vertical Milling Machine

- Babcock Wilco E Type Mill Consultant

- Plant Potash Processing

- Crushing Plant Manufactures

- Crusher Machine Conveyorbult Advantages

- Mining Lining Alumina Tiles In Cameroon

- Induksi Pada Mesin Crusher

- He Background Of Ball Mill

- Sencond Hand Gold Spiral Separator From Australia

- Effects Of Single Stage Crushing Of Coal

- Need Info On Pioneer Ve Crusher

- Titano Vanadium Magnetite Mineral Composition