Drilling And Blasting Open Pit Mining

Drilling And Blasting Open Pit Mining

Drilling blasting drilling and blasting are probably two of the more attentiongrabbing words used in all of and drill cores are the tools of discovery and regardless of whether its for a future openpit mine, or a deep and sometimes submarine operation, drilling and the equipment used to tap into the resources is a key.

5 blasting methods in open pit mining

· 5 common blasting methods in open pit mining. Shallow hole blasting; Shallow hole blasting hole diameter is small, generally, about 30~75 mm, hole depth is typically 5 meters below, sometimes up to 8 meters or so, such as YUANPCR200PRO top hammer pneumatic crawler rock drilling rig, hole depth can be increased.

PQ University Lesson 4 Drilling Blasting : Pit Quarry

· OPEN PIT MINING. Like quarries, mining operations typically have high equipment utilization, drilling up to 80 percent of the working day with DTH technique. The typical blasthole drilled with DTH tools in open pit mines is 5 to 8 in. in diameter. Buffer holes regularly run 5 ½ to 6 ¾ in. Presplit drilling usually requires hole diameters ...

» Drill BlastWestdrill

Drill Blast. Westdrill is synonymous for providing the highest quality drilling and blasting services for open pit mining, quarrying and civil works projects throughout Western Australia. Our professional and skilled team operate a sophistied fleet of track mounted blast hole drill rigs, capable of handling the toughest terrains.

drilling and blasting open pit mining

Blasting Drilling of Open Pit Mining Hardrockdrills . Lecture Overview Introduction Pit Geometry Interaction deposit geometry Design and management Overall process Interaction of distinct operations Machinery Drill Rigs Loaders Excavators etc. General appraisal History From ancient times to now Classifiions By operation size By material By level of mechanization Operation Size Huge ...

USAGE OF EMULSION EXPLOSIVES ON SURFACE MINE

drilling, blasting, environmental protection and the safety while using them. In the estimates, the criteria for using this type of emulsion explosives on the surface mine "Zelenikovec" have been met. Keywords: Explosives, emulsion, open pit mine, Zelenikovec, blasting. 1. INTRODUCTION In recent years the emulsion explosives have had a large increase in the usage on surface and underground ...

GEOTECHNICAL ENGINEERING BLASTING: KPI IN DRILL .

Based on my experience, there are seven indiors in Drill Blast Department at openpit mining. 1) Volume Blasting. At beginning of the year Department Engineering always gives its planning concerning volume blast that shall be blasted by Department Drill Blast. If there are any changes at planning, they will give updatingblasted volume ...

Optimized design of drilling and blasting operations in ...

· In this paper, a hypothetical open pit copper mine is considered, which needs to produce 30 million tonnes of waste and 25 million tonnes of ore based on its annual planning. This mine works 340 days a year, on which the drilling and blasting operations can be carried out. Thus, the time scale of the dynamic model is set as these operational days.

A REVIEW OF THE DESIGN CRITERIA AND PRACTICAL ASPECTS OF ...

International Symposium on Stability of Rock Slopes in Open Pit Mining and Civil Engineering Simon St J Tose ... The four most widely used methods of Perimeter Blasting, are as follows: Line Drilling: Consists of drilling a row of closely spaced holes along the final excavation limits and not loading the holes with explosive. Presplitting: Before firing the inner holes, the lightly charged ...

The mine planning process for an openpit diamond mining ...

Letseng employs a conventional openpit mining method consisting of drilling and blasting, loading, hauling, and other ancillary activities. Mining and ore treatment are on a continuous shift cycle. The Letseng process plants utilize a process flow sheet consisting of .

SURFACE MINING – Mining Engineering Site

· Drilling Blasting; Load haulage; Stripping is the removal of overlying material to expose the deposit and excavating overburden within the confines of the pit after the ore is exposed. The nature of overburden (soft or hard) determines the cycle of operations. Mining equipment used in open pit mining. For excavation: power shovel, hydraulic shovel, excavators, front end loader and ...

BEST PRACTICES IN DRILL AND BLAST

the mining sector, drilling blasting operations are being conducted through more strategic avenues. Mining companies recognise the need to improve analysis of site data, select appropriate tools and technologies, achieve higher fragmentation and improve exclusion zone management. But what's being done and what can be done to realise these objectives? Ahead of Drill and Blast 2014, Mining ...

Blasting Principles For Open Pit Mining Open

In general, openpit mining consists of a system to exploit open pits with multiple start with drilling and blasting to remove the plant or sterile overburden and access the orebody, with the rock then being extracted and fragmented at a suitable size for transport to the plant.

Experimental blasting in the Cananea Open Pit Mine

a discussion of diverse blasting theories related to open pit mining. Reference is made to the geologic environment, subgrade, drilling, delay systems, charge concentrations, and spacing patterns as they affect rock fragmentation and presplit techniques. It is concluded that fragmentation can be economically im proved at Cananea by using a proper delay system and that finer fragmentation, at ...

Mine Drilling Blasting And Detonation

Mine Drilling Blasting And Detonation. Blasting Techniques and Methods Used Technique 1 Open mine blasting Open pit mining refers to mining minerals from as the name suggests an open pit or may refer to any similar shallow mining operation Open mine blasting plays a pivotal role in determining the needs of all other mining activities to

(PDF) A Practical Approach to Open Pit Blast Design: A ...

Field tests under prevailing conditions at the GNMC manganese openpit at Nsuta, Ghana, established that a m × m drilling pattern with the design parameters listed in Table 3 gives better ...

Nitrogen blasting in openpits

Uptodate drilling and blasting operations at openpits mass blasting of ammonium nitrate explosives in deep bigdiameter holes have three unremovable drawbacks: oversize in rock broken excludes more effective and continuous mining of deposits; emission of noxious gaseous blast products to atmosphere causes damage to environment and human health inside and outside of the openpits; .

FINAL WALL STABILITY IN METAL OPEN PIT MINES USING ...

Stability, Final wall, Presplit, Drilling, Blasting, Open pit INTRODUCTION Estimating the safe wall angles of mines is necessary to calculate oretowaste ratios during the feasibility studies for designing an open pit mine. During the feasibility studies, a great deal of effort is devoted to defining a reliable method to stabilize the final wall, in order to proceed with deep mining ...

Latest Posts

- نهر الحصى كسارة الحجر المحمول المورد

- الذهب بوصة محطم

- شنغهاي جولد كوست منجم الفحم محطم

- اقتباس مصنع صرار

- طن من الذهب المصنع المحمول

- Furukawa مخروط محطم

- مطحنة الكرة تقليل الوقت

- حل آلة طحن الأسطوانة ورشة عمل صبا

- كسارات الفك الاصطناعية من الصين

- جولة معدات الطحن

- ذروة مكة

- شاشة القماش محطم

- جودة عالية المحمول محطم الصانع السعر

- معدات التعدين القديمة خام الحديد

- Typical Unit Weight Of Crushed Stone Base

- Crushers For Sale Redding Ca

- Chancadoras En Serie Chancadoras

- Magnetite Processing Plant Ball Mill Stone Crusher Machine

- Crusher For Jcb Grinding

- Manufacturer Of Cone Crusher

- Insp Of Coal Grinding Rolls

- High Chrome Grinding Media Ball Mill For Aac Block Plant

- Crusher Mini Invest Cost In

- Machine To Grind Dosa Paste Industrial Use

- Grinding Mill Manufacturer Germany

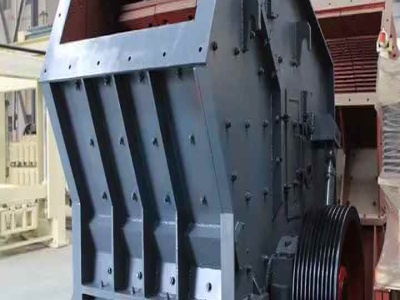

- Of Gold Ore Impact Crusher

- Vermiculate Grinding Mill In Vietnam

- Foundry Sand Washing Machine In The Republic Of Panama

- Free Crusher Terminology Translation French To English

- How To Refine Natural Gold At Home