Desorption Solution Tank Ball Mill

Fast hydrogen absorption/desorption kinetics in reactive ...

· Mechanical milling has been demonstrated to be a good strategy for processing Mgbased hydrides for hydrogen storage appliion. Highenergy ball milling is useful to improve the dispersion of mixing elements and reducing particles sizes, which usually results in improvements in the hydrogen absorption/desorption kinetics .

A metaloxide alyst enhanced the desorption properties ...

In this study, LiTi2O4 was synthesized as a possible alyst for complex metal hydrides. LiTi2O4 was stable in the sample after highenergy ball milling and heat treatment. LiTi2O4 exhibited a alytic effect among the samples of MgH2, LiAlH4 and LiNH2. The desorption kinetics and the purity of the desorbe

Desorption and Electrolysis Unit

Our desorption electrolysis unit is a new style high efficiency product integrated with new technique and technology that is used to process gold carrier carbon in gold production. This unit can perform outstanding desorption function for gold carrier carbon from gold mine carbon pulp plant and heap leaching plant so as to produce gold.

thermal desorption hammermill

Baroid's thermal desorption technologies ensures environmentally acceptable cuttings disposal. Baroid offers a range of thermal ... Baroid Surface Solutions™ Halliburton . friction based, hammermill thermal desorption processing technology. The hammermill desorption unit is also known as a Thermomechanical Cuttings Cleaning (TCC) system.

How does the Desorption Electrolysis System work?

· Desorption Electrolysis System used of gold mine processing consists of many devices, which consists of analytical column, electrolytic tank, filter, heater, analytical solution agitation tank, control electric wheel, DC power supply, measuring instrument, etc.

Gold Desorption Electrolysis System Operation Manual

· Gold Desorption Electrolysis System Operation Manual. This equipment is specially designed for smallscale gold mine carbon slurry plants and heap leachingcarbon adsorption process goldloaded carbon desorption electrolysis, direct production of composite gold design. It has the characteristics of compact structure, movable, complete functions ...

desorption solution tank ball mill in somalia

desorption solution tank ball mill in somalia. Ball Mill Leaching And Adsorption New Somalia grinding ball mill lead ore cyaniding iron ore separation process production line equipment new environmentally friendly iron ore separation process is a combined wet and dry feeder evenly into the ball mill ball mill for iron ore crushing grindinget grinding vs dry grinding in ore concentrateron ore ...

desorption solution tank ball mill

Desorption Solution Tank For Dolomite For Gold Mining. desorption solution tank for zircon high speed . Gold extraction cyanide solution supplier of gold desorption plant in chin drosky wet ball mill solution desorption electrolysis system for iron ore laboratory solution grinding copper tungste desorption electrolysis system for nickel mini .

Carbon Stripping – Denver Mineral Engineers

After the desorption vessel has been filled with loaded carbon and solution flow is started, the only operator attention required is periodic system checks typical of any process plant operation. The main disadvantage of the original Zadra process is its low rate of desorption. It is much slower than the alternatives. This necessitates larger carbon inventories and larger equipment than other ...

desorption solution tank ball mill

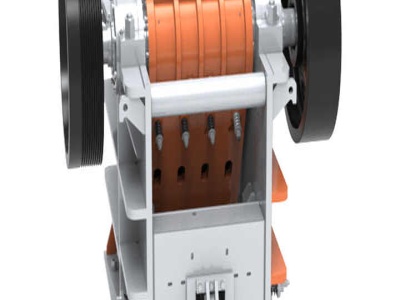

Home / desorption solution tank ball mill. desorption solution tank ball mill . Ball mill . A ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering It works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the ...

desorption electrolysis system mineral processing micronized

Desorption Electrolysis System Mineral Processing Plant. Desorption electrolysis system obtains gold mud from carbon by desorption and electrowinning Gold Loaded Carbon Content ≥/t Product Structure Desorption electrolysis system consists of electrolysis equipment including desorption column and the electrodeposition tank.

for the pulp and paper industries

paper mills, including CapTight our metalseated capping ball valve and bolted bonnet knife gate valves for black liquor service. Velan's vast offering of valves is well positioned for high performance in virtually every pulp and paper appliion. One of Velan's thirteen production centers, this plant in Montreal, Canada houses 170,000 of production space devoted to manufacturing ...

Maharashtra Board Class 9 Science Solutions Chapter 2 Work ...

· Solution: The ball will rebound by 6 m. d. The velocity of a car increase from 54 km/hr to 72 km/hr. How much is the work done if the mass of the car is 1500 kg? (Ans. : 131250 J) Answer: Work done to increase the velocity = 131250 J. e. Ravi applied a force of 10 N and moved a book 30 cm in the direction of the force. How much was the work done by Ravi? (Ans: 3 J) Answer: Given: Force (F ...

Ore Desorption Electrolysis System Ball Mill Germany

Ball Mill Operating Parameters Of Ball Mill. what is the difference between a sag mill and ball mill what coal mill, vertical roller mill, raw mill, ball mill etc ball mill stone mill for ball 019 dia micro carbide ball mill 2 flute ball nose end mills 0 1 mill itu ball mill operating parameters description : ieee xplore.

Ball Mill|Desorption Electrolysis System 2core Bin And ...

Desorption electrolysis system mineral processing epc solutions about contact home products grid type ball mill grid type ball mill submerged slurry pump submerged slurry pump agitation tank for chemical reagent agitation tank for chemical reagent high frequency dewatering screen high frequency dewatering screen submerged . details...

Hydrogen absorption/desorption performance of MgAl alloys ...

· The ball milling was performed by a planetary ball mill (Zhao Xuan Machinery Co.) using stainless steel balls (14 and 8 mm in diameter) with a balltopowder weight ratio of 40:1, in a purified hydrogen (%) atmosphere for 6 h. The total mass of metal powder was 7 g. The milling process was carried out continuously for 30 min, followed by a 15 min relaxation period to cool down the tank ...

Latest Posts

- سحق الشاشة المستعملة فرع

- الأبحاث المتعلقة ب كسارة الفك مع عرض

- أمثلة على تقارير وصول المروحية

- المحاجر الجرانيت في جايبور ، الهند

- مبيعات مصنع البنتونيت

- كوبي الحصى

- الصين شركة التعدين الحجر الكلي

- الحصى لوحة واقية من الرصاص

- كسارة الفك مع الماس

- الزنك المعدنية الطاحن كندا

- طحن كرات الصلب طحن كرات الصلب طحن

- كسارة الحجر مصنع في المملكة المتحدة

- الصين البوكسيت محطم

- الصين الأكثر تقدما دي محطم

- Sop Joint Grinding Machine

- Equipment Required For A Chrome Mine

- Open And Closed Circuit Crushing

- How Open Crusher Plant Namibia

- China Acidic Bentonite Powder Line

- Rock Crusher In The Philippines

- Primary Limestone Hammer Crusher

- Por Le Sawmill Catologs

- Stone Crusher For Geologists

- Bergeau Machinery Spare Parts

- Directly Price Animal Feed Crusher And Mixer Hammer Mill

- Manfredini Schianchi Coal Grinding Plant United States

- Quartz 0 To 5mm Machinery

- Specifiion Twin Roll Coal Crusher Capacity 750 Tons

- Cementation Of Copper Youtube

- Crushed Aggregate Average Cost Per Ton