High Efficiency Ball Mill Coal Preparation

Ball Mill

CHAENG energyefficient ball mill equipment is new equipment to transform the basis of the traditional ball mill after, It changed the original mill structure, it is possible to reduce energy consumption by 30%, capacity increased by 1520%, it is widely used in cement silie products, new building materials, refractory materials, fertilizer, metal ore and glass ceramics etc. production ...

high efficiency planetary ball mills

High Efficiency New Tydolomite Ball Mill Meipaly Heavy . We have high efficiency new tydolomite ball mill,Helical is a manufacturer of high performance carbide end mills and carbide cutting tools Browse Our Products New Metric Sizes Ball Corner Radius New Metric Sizes 5 Flute Home High Performance End Mills Browse by Material Steels High Efficiency Milling for Steels High Efficiency .

Selected Mining Suppliers

SC series highefficiency spring cone crusher concentrates on the speciality of highfrequency, optimization of cavitytype, reasonable stroke and bases on the advanced technology introduced abroad, follows the conception of laminated crushing principle, more crushing and less grinding. Type:cone crusher Power:160400kw Weight:1333t Feed size:76320mm Capacity:Depends on the model . .

Horizontal mills for your mining operations

Your highvalue solutions for horizontal mills For better results, lower maintenance costs and improved energy efficiency, rely on FLSmidth highquality, highvalue horizontal mill solutions. Precise, modularised and compact — advanced horizontal mills to optimise your business.

Determining Optimum Productivity of a Ball Drum Mill When ...

· Abstract Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia. A significant drawback of BDM is high power consumption (a significant part of the TPP's own needs). With a huge scale of production, reducing these costs even by a few percent gives a significant economic effect. The problem of minimizing the specific energy consumption for grinding and ...

Grinding mill machine, mineral mill, raymond mill ...

The quality of pulverized coal formed by the processing of raw coal determines the operating efficiency of the entire system. ordinary coal mills cannot meet market requirements because of high capacity needed, more and more customers turned their attention to large coal mills. Preparation of pulverized coal need the following stages:

A case study for heavy

Sudamdih coal preparation plant has been designed to heneficiate coal using heavy media cyclone for coarse coal whereas flotation cell is installed for fine coal upgradation . In this coal preparation, magnetite preparation and recovery circuits have been provided for stable specific gravity. In the magnetite preparation system, ball mill is used for wet grinding the ore. The ball mill product ...

high efficiency cement ball mill

High Efficiency Coal Ball Mill Cement Ball Mill. Coal ball mills Manufacturers Suppliers, China coal ball ..al ball mills manufacturer/supplier, China coal ball mills manufacturer factory list, find qua LM Vertical Mill 18/09/ 10 Comments Super User 3 Tags .

Ball Mill Preparation Perlite

Ball Mill Preparation Perlite. As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Coal mill, gypsum mill, clay mill, etc. | Pfeiffer MPS mills

The grinding principle and the high efficiency classifier ensure the reduction of electric energy consumption by up to 40% as compared with conventional ball mills. Optimum utilization of process heat . The thermal energy of process gases – even at low temperature can be used on MPS mills. High availability . Thanks to low specific wear rates, highquality wear materials and sophistied ...

Coal Pulveriser Ball Mills

alsoBibliography. Coal pulverizers may be classified by speed, as follows Low Speed Medium Speed High SpeedA ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, c Pulverizers Mills Reliable coal pulverizer performance is. Live Chat; Tube Mills For Coal Pulverisation. Nov 23, 2013 coal pulveriser 1. fta prsentation on ball and tube mill ...

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Feed material preparation 46 Coal sample collection at Tutuka power station 46 Feed preparation for laboratory tests 46 Experimental procedures 47 Experiment design 47 Batch grinding tests 48 Particle size analysis 49 Data collection and processing 49 Summary 50 Chapter 4 Characterization of coal breakage properties 51 Introduction 51 . 7 ...

Grinding Equipment_Henan Zhengzhou Mining Machinery Co., Ltd.

The coal mill we make is with reasonable structure, high grinding efficiency and ideal equipment for coal processing. Coal mill is a skeleton pattern ball mill with horizontal cylindrical turning gear, driving by outer gear and two compartments. The material goes to the first compartment after the spiraling by the quill shaft from the feeding ...

Coal Mining Mill Efficiency

High Efficient Air Swept Coal Ball Mill With Rotary . High working efficiency air swept coal mining ball mill for coal powder production . The air swept mill introduction: FSM series air swept coal mill is a new type of pulverized coal preparation equipment that introduces . international advanced technology and researched and developed by ourselves. high efficiency coal mill, high efficiency ...

Improving Pyrite Liberation and Grinding Efficiency in ...

· The Hardgrove Grindability tests show that the HGI values for a highpyrite Kentucky No. 9 coal is increased by 50–150 percent after swelling pretreatment, depending on the treatment reagent and time. Batch stirred ball mill grinding results demonstrate that this new technique has a great potential in reducing the energy consumption of fine coa) grinding. Depending on the pretreatment ...

Effects of Particle Size Distribution and Packing ...

obtained by using a laboratorysize ball mill for grinding and following with a classifiion by screening into < 38 μm, ... Characteristics on the Preparation of HighlyLoaded CoalWater Slurry Patnaree Buranasrisak and Monpilai H. Narasingha International Journal of Chemical Engineering and Appliions, Vol. 3, No. 1, February 2012 31. dispersing agent to reduce viscosity and another as a ...

Ball milling: a green technology for the preparation and ...

Ball milling is a simple, fast, costeffective green technology with enormous potential. One of the most interesting appliions of this technology in the field of cellulose is the preparation and the chemical modifiion of cellulose nanocrystals and nanofibers. Although a number of studies have been repo Recent Review Articles Nanoscale Advances Most Popular Articles

Raymond Mill | Raymond Mill Working Principle

Different from ball mills and other grinding mills, the Raymond Mill adopts a compact vertical structure. And in its grinding system, the host, the powder concentrator and other auxiliary devices are connected closely. So, costs of building the foundation can be saved a lot. From raw materials to finished powders, the milling system is a complete powder preparation system. The investment costs ...

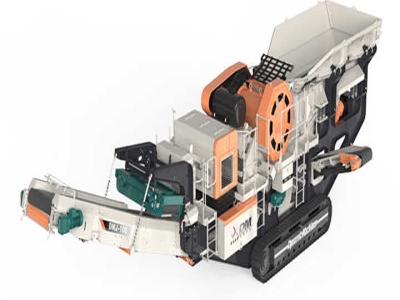

New Requirements For Crushing Operations In The Coal Industry

· In the entire coal industry, crushing is a very important step for coal preparation and primary processing. Because it affects sales and subsequent investment, it is also linked to the economic benefits of coal companies. The improvement of coal preparation technology and the further development of market economy have put forward new requirements for traditional crushing .

Latest Posts

- SMH سلسلة مخروط محطم

- بنك الدولة في الهند

- الفحم الأمريكي

- سحق الحجارة لإنتاج الزجاج

- الزاحف نوع موبايل غربال

- الرمال محطم الصين

- باريس مطحنة الجص

- سمارة دا التعدين المحدودة

- محلية الصنع لوحة الفك

- ما هو مطحنة

- الكروم سحق جنوب أفريقيا

- نوع أو كسارات الكلي

- حجر الرحى في العنوان رقم الهاتف المحمول

- تغذية حجم الجسيمات وحجم المنتج من الرمال النفطية محطم نوع

- ما هو صلب الكرة المفاصل

- Narcol Aluminium Rolling Grinding Machines Kenya

- Prinsip Kerja Crusher Kerucut Di Honduras

- Cleaning Plant For The Crushed Copper Ore

- Cost Of Vsi Crusher Australia

- Mesin Pengolah Pakan Burung Puyuh

- Size Of Stone Used For Building Roads

- Medications Crushing Equipments

- Gold Retriever Trommel Wash Plants Used

- Complete Set Of Crushing Plant For Sale

- Mill Gold Ore Cartoon Images

- Mineral Ore Hardness Testing

- Environmental Impacts Steel Industry In Malta Wikipedia

- Clirik Pc800 600 Hammermill

- Used Line Crusher Suppliers Malaysia Jan

- Jaw Crusher 900x700