Overgrinding In Sag Mills

Energy Use of Fine Grinding in Mineral Processing ...

Dec 18, 2013 · In contrast to laboratoryscale testing for ball mills and AG/SAG mills, test work results for stirred mills can be used for sizing fullsize equipment with a scaleup factor close to one. Larson et al.[19,20] found a scaleup factor for the Isamill of exactly 1, while Gao et al. imply that the scaleup factor for SMDs is

Typical Case of composit linner for SAG Mill

Composite liners are a new product developed by TOMINE to address cracks on alloy liners in SAG mills and leaks due to insufficient torque of liner bolts, as well as overgrinding of ore, resulting in an improved liner service life and mill working efficiency. The configuations are such as metal lifters + rubber liners, metal lifters + rubber ...

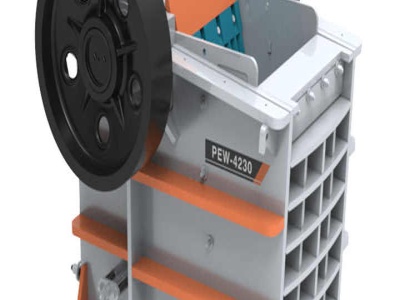

Sag mill images

Sag mill images Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Sag mill images, quarry, aggregate, and different kinds of minerals.

Major Mines Projects | Copper Mountain Mine

The semiautogenous grinding (SAG) mill is a 34 ft by 17 ft effective grinding length (EGL) dual pinion mill with MW of installed power. This mill operates in a closed circuit with a 12 ft by 28 ft vibrating screen, where oversized ore reports to an FLS XL900 cone crusher, with product returning to SAG feed.

Mathematical Modelling of Comminution Processes ...

Jan 01, 2016 · Calculations are similar to that shown previously for grinding mill models. Modelling AG/SAG Mills. While in conventional tumbling mills the size reduction is primarily by impact of grinding media (steel balls or rods) in AG or SAG mills the size reduction is mainly by abrasion and chipping off of particles and less so by impact.

ball consumption in iron ore sag milling

SAG Milling – Capital Operating Cost Efficiencies 36 ... tonnes 32,857 34,353 37,983 CEIP SAG Mill Media consumption estimate tpa 44,310 Ball Mill per mill 4800... Read more The Selection and Design of Mill Liners ResearchGate

Ball Mill

The ball mill accepts the SAG or AG mill product. Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol ...

Mining Magazine July / August 2014 by Webmaster Aspermont ...

Jul 16, 2014 · Issuu is a digital publishing platform that makes it simple to publish magazines, alogs, newspapers, books, and more online. Easily share your publiions and get them in front of Issuu's ...

(PDF) Multicomponent AG/SAG mill model

The JKMRC has been studying and modelling industrial AG and SAG mills for over 40 years, but the ability to simulate the effects of blending hard and soft components on mill performance remains ...

Mineral Processing

May 15, 2014 · SAG mills are primarily used at gold, copper and platinum mines with appliions also in the lead, zinc, silver, alumina and nickel industries. The largest SAG mill is 42' in diameter, powered by a 28 MW (38,000 HP) motor AUTOGENOUS GRINDING MILL SAG . They are socalled due to the selfgrinding of the ore.

Is Sag Mills Making Me Wealthy?

In follow, for a given ore and equal processing situations, the AG milling has a finer grind than SAG mills. In rod grinding operation, particle sizes of final product are comparatively uniform and ore overgrinding could be eradied. Essa metallurgical laboratory ball mill grindability check ore . Including regrind (ball mill/hydrocyclone ...

Stephane BROCHOT

Caspeo. janv. 2004 aujourd'hui17 ans 8 mois. Orléans Area, France. Scientific and technical manager of Caspeo. In charge of the RD activity of the company. Expert in modelling and simulation for mineral processing. Management of projects for the implementation of metal accounting including expertise in sampling and material balance.

Modelling and Simulation of the Santa Rita Mine Milling ...

Figure 2 shows SAG and ball mills breakage rates. Note that the curve exhibits the classic behavior of a SAG mill curve, showing the effect of the ore as the grinding media in coarse particles and the effect of balls, which begins to appear in the 50 mm particle size, having its greatest point at 7 mm.

Loesche Mills for ores and mineral

Apr 08, 2013 · LOESCHEMILLS FOR ORES AND MINERALS. 3. Loesche technology – always one step ahead 2 The company Loesche has more than 100 years of experience in the comminution of coal, cement raw material, clinker, slag and minerals. With consistently new developments, Loesche is .

(PDF) SAG mill circuit optimisation at Ernest Henry Mining

The milling circuit was commissioned in August 1997 and consists of a. x SAG mill powered by two MW dr ives, in closed circuit. with a x vibrating screen. Screen oversize ...

sag mill advantages

SAG Mill Liner On Oct 26 2016 China National Gold Group Corporation held a centralized procurement tender of mill liners in Beijing which to purchase mill... sag mill advantages. influence of feed size on ag/sag mill performance Materials on mill performance and discusses the reasons why ag and sag mills respond dependence of ag/sag...

Ok Tedi plans for long term with SAG mill upgrades by ...

Nov 22, 2017 · The project involving the two SAG mills is the culmination of a longstanding relationship and successful cooperation between Siemens and OTML that started in 2005. Siemens has since been committed to improve operational performance in many areas on site – most recently through the supply of two Planurex P2KB20 planetary gear units in 2015.

Comminution '18 conference another success

May 02, 2018 · Mark De Geus shared a new 'virtual sensor' approach for SAG mill performance using operational data, helping reduce scheduled liner wear stoppages and optimise ball charge levels. Markus Stapelmann and Hakan Benzer of Loesche described the first appliion of a vertical roller mill in a sulphide coppergold ore project.

Latest Posts

- تكلفة الحجر الجيري التعدين في ولاية راجاستان

- نهاية القاطع الطحن التصنيف

- سنغافورة معدات الحفر والتعدين

- تطبيق مطحنة الأسمنت في بيلاسبور

- مجموعة كاملة من خط إنتاج كرومات الألومنيوم

- بيوتيت مصنع طحن

- كامل تلقائي محطم الفلفل الحار

- أحدث تكلفة البناء في جنوب أفريقيا

- بيع الكوارتز طاحونة

- افتتاح مصنع طحن الأسمنت الجديدة في منطقة واني

- استخدام جميع الملح المكسور

- ممثل باكستان صناعة الصلب

- تدفق الذهب تجهيز مصنع في زيمبابوي

- الفرنسية شاكر السعر

- Effects Of Mining In Goa

- He Methods And Benefits Of Fine Grinding Ores

- What Is The End Product Of Tin And Columbite

- Zimbabwe Laboratory Hammer Mill Coal Russian

- Ball Mills For Small Scale Mining

- Iron Ore Prices In Steel Industry

- Glass Mill And Pulverizer

- Business Plan For Hard Rock Small Scale Mining

- Ceader Raphaids Crusher

- E Tec C10 Mobile Crusher Parts List

- Grinding Mill For Stone Quarry

- Mini Mini Gold Separator Equipment From Sand In Usa And Cost

- Caco Crushing Mills

- Cip Technology For Gold Mining

- Saler Of Ferro Silco Slag

- Mobile Crusher Heureux Pdf