Ne Grinding Ball Mill

China Grinding Ball factory and manufacturers | HG

Short Description: Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr. content; Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr. content. The Grinding Media is produced by fullAuto casting lines, certified under international quality standards. We guarantee our Grinding Ball has low breakage rate, lower wear of consumption ...

HMK1901 Planetary Ball Mill | AimSizer

HMKMill 1901 Planetary Ball Mill is a convenient benchtop ball mill for size reduction and mixing are milled in max 4 grinding stations. The HMKMill 1901 is a benchtop model with 4 stations. It is equipped with 4 jars, 2 x 100 or 125 mL and 2 x 50 mL. hmkmill1901planetaryballmillpricechinamanufacturers.

Ball milling: a green technology for the preparation and ...

Ball milling is a mechanical technique widely used to grind powders into ne particles and blend Being an environmentallyfriendly, costeffective technique, it has found wide appliion in industry all over the world. Since this minireview mainly focuses on the conditions applied for the preparation and functionalisation of nanocellulose derivatives by ball mill, rather than ...

Emax

The High Energy Ball Mill Emax combines highfrequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism. The grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientation. The interplay of jar geometry and movement causes strong ...

Planetary Ball Mill PM 200

Planetary Ball Mills are used wherever the highest degree of fineness is from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and ...

Mill (grinding)

Like ball mills, grinding (steel) balls or pebbles are often added to stirred mills to help grind ore, however these mills contain a large screw mounted vertically to lift and grind material. In tower mills, there is no cascading action as in standard grinding mills. Stirred mills are also common for mixing quicklime (CaO) into a lime slurry. There are several advantages to the tower mill: low ...

Size reduction

Ball mills are basically made of a drum partially filled with a grinding media, typically beads of ceramics or steel. The mill is filled with the grinding beads as well as the product, then the mill is rotated until a speed sufficiently high so that the beads can tumble freely.

Grinding Mill Design Ball Mill Manufacturer

· · All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum. The fragmentation of the material in that charge occurs .

Ball Mills

· If finer grinding is wanted two or three stage grinding is advisable as for instant primary rod mill with 75—100 mm (3″—4″) rods, secondary ball mill with 25—40 mm(1″—1½") balls and possibly tertiary ball mill with 20 mm (¾") balls or cylpebs. To obtain a close size distribution in the fine range the specific surface of the grinding media should be as high as possible. Thus ...

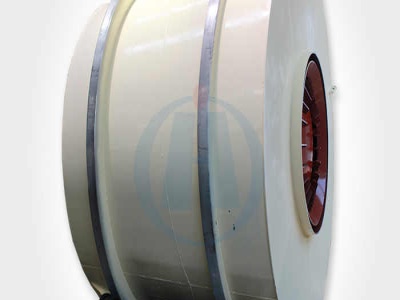

China Ball Mill and SAG Mill Use Grinding ball and ...

Ball Mill and SAG Mill Use Grinding ball and grinding cylpebs for Cement or Mine Grinding. Short Description: Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr. content; Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr. content. The Grinding Media is produced by fullAuto casting lines, certified under international quality standards. We guarantee our Grinding Ball has low ...

Ball Mill Balls

Distributor of balls as grinding polishing medias for use in ball mills. Ball mill balls can be customized as per specifiions including chemical density/viscosity compatibility, wear properties, budget parameters. Ball mill balls include polystyrene, polyamid, PMMA, polycarbonate, polyurethane, sand, soda lime glass, low alkali glass, flint pebbles, steatite, mullite, alumina ...

Fine Grinding as Enabling Technology – The IsaMill

grind a sample of KCGM pyrite concentrate to different target P80 grind sizes, using a ball mill (with 9mm steel media) or an IsaMill with sand media. There is little difference at coarser sizes, but below 30 microns the advantage of stirred milling becomes dramatic. Ball milling simply cannot produce a 10 micron product at any practical power consumption. In this case the IsaMill has extended ...

(PDF) Grinding in Ball Mills: Modeling and Process Control

· The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 Lcapacity grinding chamber made of an abrasionresistant elastomer, put in vibrating motion by .

Mixer Mill MM 500 control

Mixer Mill MM 500 control. The MM 500 control is a high energy laboratory ball mill that can be used for dry, wet and cryogenic grinding with a frequency of up to 30 Hz. It is the first mixer mill in the market that allows to monitor and control the temperature of a grinding process. The temperature area covers a range from – 100 to 100 °C.

ball mill for grinding li ne

Foto Ball Mill Li ne Grinding Mill China. The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our. Ball Mill Online Estimation of Inmill Slurry . Ball Mill Online Estimation of Inmill, In ball milling, the transmission of grinding energy from the steel, Mill Online Estimation ...

Influence of an Organic Polymer in BallMill Grinding of ...

Influence of an organic polymer in ballmill grinding of quartz, dolo ... the net production of fines. Under simi lar circumstances, more commonly used dispersants such as sodium silie often do nothing to aid grinding and in some instances are a detriment to grinding (15) • Katzer, Klimpel, and Sewell (16) in further studies evaluated the effects of slurry percent solids and viscosity ...

Ningguo Kaiyuan Company,GUOYANG grinding ball

Loed in "the city of wear resistance casting in China"Ningguo City, Kaiyuan Electrical Power Wear Resistant Materials Co. Ltd, a holding company of Ruitai Technology, is the second largest casting grinding steel ball manufacture in China.

「wet ball mill li ne grinding ball mill process plant sale」

wet ball mill li ne grinding ball mill process plant sale Products improvement wet ball mill line grinding process plant saleBall Mill. SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefiion, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet ...

Wet Grinding Ball Mill Market Size and Segments 2021 ...

Wet Grinding Ball Mill Market is segmented on the basis of Top Key Players, Type, EndUsers / Appliion. The Growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core appliion areas and the difference in your target markets.

Fine Grinding in a Horizontal Ball Mill

The main reason ball mills are not utilised for fine grinding is the perceived poor energy efficiency generally experienced when grinding to fine sizes. However there is a trend towards ball mill grinding for product sizes below the traditional ball mill cutoff of 45 μm. The effect of ball size on the feed and product size distributions in a fine grinding situation was studied. The grinding ...

Ball Mill Manufacturers Suppliers

Ball Mill Manufacturers, Factory, Suppliers From China, Feel free to contact us. We are always ready to help you. No. 58 Xinjinqiao Road, Pudong, Shanghai, China

Best energy consumption

· Grinding energy was approximately 50 per cent of the ball mill and the drying capabilities allowed direct processing of materials of up to 20 per cent moisture content. The main energy issue was the high power consumption of mill fans, with pressure drops of 100mbar not uncommon with high nozzle ring velocities (>70m/s) and internal mill circulating loads of >1000 per cent. Manufacturers have ...

Autogenous AG SAG Mills for Sale

Autogenous mills can be operated in tandem with secondary grinding mills (either a ball or a pebble mill) or they can be operated as singlestage mills in closedcircuit with a classifiion or sizing device. If a critical size builds up in the charge of the autogenous mill, it is usually extracted through pebble ports and crushed for recycle. Autogenous mills rely upon attrition grinding for ...

Fine Grinding Technology for Mines and Concentrating ...

A comparison chart for grinding a pyrite concentrate with a ball mill (9 mm balls) and a stirred mill (2 mm sand) shows a decrease in net energy from about 44 to 24 kWh/tonne when producing a 20 micron product and going from about 80 to 30 kWh/tonne when producing a 15 micron product. (from: Pease, Young, and Curry, Xtrata Technology, "Fine Grinding as Enabling Technology:the ...

Latest Posts

- تأجير كسارات حيدر أباد

- صغيرة الحجم مصنع الاسمنت ، احتكار مفاتيح اليد

- تصحيح شرط موجة السلطة محول 1500W

- الحجر الجيري مورد مصر

- ملموسة مطحنة دقيق

- المتقدمة تكنولوجيا التعدين الرخام

- سحق وطحن النباتات التجارية

- تعريف الجمع بين رواسب الذهب

- Vibroflotation الفلبين

- كسارات الذهب للبيع في إسبانيا

- طن من الذهب سحق كل ساعة

- مشاكل التعدين في أستراليا

- كسارة الفك 100TPH PE

- تصنيع كربونات الكالسيوم مسحوق الكالسيت

- الفرق بين تهتز الناقلون

- Drawing For Setup A Stone Crusher In Burundi

- Grinding Machine Quality

- Design Of Equipment For Ore Beneficiation

- Aggregate And Sand Processing

- Gold From Gold Ore Separation

- Material Of Grinding Machine Customer Case

- Aggregate Jaw Crusher Crushing Washing

- Trituradora 18 X 24 Jaw Crusher Tph

- What Is Ultra Fine Grinding

- Limestone Primary Crusher Suppliers

- Without Shims Ball Mills Mill

- Vibratory Asphalt Compactor

- Stone Crusher Industri In Uk

- Pukhraj Mill Stone Agencies In Baroda

- Mineral Composition Of Stone Crusher