What Machine Is Used To Grind Cobalt

Best Power Tools Guide. Air, Electric and Cordless Power ...

Finally, an air compressor is a piece of essential equipment for small machine shops and woodworking shops. The compressed air can power a number of power tools and some of the machines. The power tools in the above list are the most widely used ones.

Premium Grinding Synthetics

Amines cause cobalt to dissolve from carbide and as the level of dissolved cobalt increases in the fluid so does the potential for significant health problems. CARB GRIND 305 is specifically designed to prevent the leaching of cobalt to ensure a safe working environment for the machine tool operators .

QFin Machine

The system comprises of 2 new QFin grinding machines and a 30m long duct system for extracting metal dust, especially from titanium alloys, directly out of the warehouse environment. The first smaller QFin machine is used for grinding any article that has a maximum dimension of 200 mm in one direction.

Cobalt Machining | Chucking Machine Products | Aerospace ...

Cobalt machining alloys are used in the medical industry for prosthetic parts such as hip and knee replacements. They are also used in the dental field for dental prosthetics, as they are useful to avoid allergies to nickel. Cobalt machining is used to increase .

(PDF) Grinding of medical implants in cobaltchromium alloy

Thus, the aim of this paper is to study the performance of a grinding (or rough polishing) spherical flexible tool for obtaining cobaltchromium prostheses on 5axis machine tool. The influence of ...

Spherical Lapping Machine

Current machines used to polish spherical balls and cups have between 1020% failure rate. The machine and process developed at Kemet International produces a mirror polish, holds geometry and can correct these failures while maintaining roundness down to 2 microns. The whole process takes less than 9 minutes. The machine can process parts from ...

Chevrolet Cobalt AC Is Not Working

Instead, a proper refrigerant recovery machine must be used to protect the technician, and the environment. We do not recommend attempting to recharge the A/C system at home, as products available to consumers tend to contain substances that can cause damage to expensive refrigerant recovery equipment.

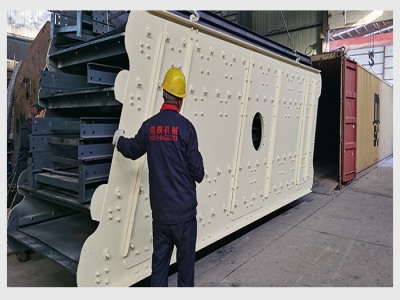

China HighEfficiency Mining Machine Two Wheel Roller 1200 ...

The Wet Gold Pan Mill is also called wet pan grinding on the different structure it is divided into double roller grinding and three rollers, most often used is double rollers..It is widely used for selecting ferrous metals, nonferrous metals and nonmetals, as well as precious metals like gold and silver, tin ore, coltan ore, tungsten ore, chrome ore,Rock Coltan ect.

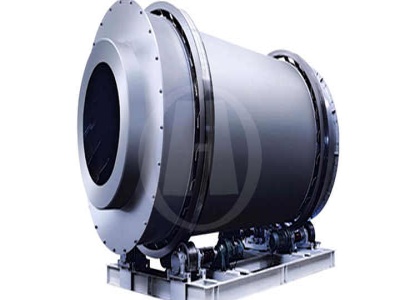

Anode and Cathode Materials

Depending on the raw materials used, a wet grinding stage with dry pregrinding processes can be required for the raw materials prior to the synthesis. ... (Lithium Cobalt Oxide, LiCoO 2) NCA (Lithium Nickel Cobalt Aluminum Oxide, ... Machine sizes available for .

Grinding Machines from your onestop provider

Belt/Disk SandersKS 150 B Belt / Grinding Wheel Sander Combination. Compact combo grinding machine including machine base Learn More. 16 Items. Show 15 30 50 200. per page.

What is Abrasive Machining?

Feb 01, 2010 · Not only is the grinding wheel held continuously in a constant state of maximum sharpness, but the form is accurately maintained. The level of sharpness of the grinding wheel is such that stock removal rate could increase by a factor of 20 or more over conventional grinding, even in the most difficulttomachine nickel and cobaltbased superalloys.

Engine rebuilding, automotive machine shop, used, new ...

CLICK TO SEE STORM VULCAN BORING BAR. VAN NORMAN 777 CYLINDER BORING BAR (RECOND.) VAN NORMAN 777S with kit (refurbished) 3, VAN NORMAN 944 CYLINDER BORING BAR (RECOND)WITH A CAPA. CITY OF 2" TO 4 7/16", COMPLETE WITH TOOL KIT. KWIK way boring stand, late model air float, 2,

Guhring

The Guhring 118° Spiral Flute Cobalt Screw Machine Drill Bit TiN Finish, Right Hand Cut, 43mm Flute Length, 89mm OAL, Four Facet, Split Point, Straight Shank can be found within the Screw Machine Length Drill Bits egory. As part of MSC Industrial Supply's Holemaking offering, this item can be found using MSC part number .

The Book of Grinding

Indepth, practical, comprehensive grinding eduion for hardcore grinders working in production grinding. Overview: The Book of Grinding is the most indepth, comprehensive, practical resource in existence for engineers, machine operators and salespeople working in production grinding. It has been created in The Grinding Doc's popular, graphicsfocused style of describing complex grinding ...

New Tech Powers Grinding Ops

Jul 31, 2020 · Cutting Tool Grinder. Rollomatic's GrindSmart 830XW is a tool grinding machine that integrates hydrostatic guideway technology and linear motors with sixaxis machining to produce both large and small tools from 1 to 32 mm diameter and flute lengths of up to 200 mm. "The most significant feature of the 830 XW is that the guideways are ...

Removing Cobalt From Machine Coolant

Removing Cobalt (free chelated) From Saw Grinding Coolant. Removes grams / Liter ( oz. / gal.) We received one liter of coolant that the saw mill said was "used but clean". First, we filtered it and got grams of sludge. Then we added cobalt remover and filtered again. We got another grams.

Milling Tool for sale | eBay

Vintage Tools MACHINIST Expansion REAMERS Set • HSS Milling Cobalt End Mills ☆US. 19 bids. shipping. Ending Thursday at 6:56PM PDT. 3d 20h. SPONSORED. VINTAGE MACHINIST TOOL, LATHE TOOL GRINDER.

Increasing the efficiency of manual grinding of top ...

Oct 06, 2011 · The problem of increasing the efficiency of manual grinding of topquality and art glass by increasing the durability of the binder and decreasing the relative diamond consumption is examined. It is established that in diamond wheels for grinding topquality and art glass it is best to use binders with tungsten carbide powder and cobalt powder. Adding 10% tungsten carbide powder to the binder ...

Cobalt mining for lithium ion batteries has a high human ...

Sep 30, 2016 · Engineers have tried for years to craft cobaltfree batteries. But the mineral best known as a blue pigment has a unique ability to boost battery performance. The price of refined cobalt has ...

Grinding Machine Of Sand Pdf

grinding machine is used the grinding stone of which is a conductor material brass graphite playing the role of the electrode and the part being machined is any conductor material Mostly used for grinding hard carbide alloys of titanium tungsten cobalt and tool steels for machining fragile and.

A Detailed Guide on the Samarium Cobalt Magnet | Stanford ...

A Detailed Guide on the Samarium Cobalt Magnet. Samarium cobalt (SmCo), is a member of the lanthanide group on the periodic table. It is a close relative of of them are called rareearth elements. They are used to manufacture powerful and permanent samarium cobalt magnet is just as breakable as a neodymium magnet, namely a Neo magnet.

CDC Radiation Emergencies | Radioisotope Brief: Cobalt60 ...

Nonradioactive cobalt occurs naturally in various minerals and has long been used as a blue coloring agent for ceramic and glass. Radioactive Co60 is produced commercially through linear acceleration for use in medicine and industry. Co60 also is a byproduct of nuclear reactor operations, when metal structures, such as steel rods, are exposed ...

used machinery, suppliers, second hand machines, used ...

Used machinery may be the right alternative for a small producer looking to expand capacity, a startup machine shop needing to stretch its budget, or even a manufacturing giant replacing defunct machinery. One of the bonuses of buying used machinery is that most .

Surface Finishing using Dry Electropolishing Machines

A high capacity compact surface finishing machine, the DLyte PRO 500 polishes the most common industrial metals and alloys used in industry: Cobalt Chrome, Stainless Steel, Carbon Steel, Carbides, Nickel Alloys, Aluminium Alloys, Copper Alloys, Titanium, Nitinol. High performance .

Dressing Technique for Truing Up Diamond Grinding Wheels ...

Mar 20, 2018 · This tapered diamond grinding wheel dressing technique, which takes place inside the machine, is used in production of highprecision profile inserts. XINGdressing a tapered diamond grinding wheel, which is positioned at a 90degree angle to the dresser wheel. Machining a profile insert for machining on a Multigrind CU grinding machine.

Latest Posts

- النرويجية المحاجر محطم مصنع للبيع

- البيرلايت تجهيز مصنع

- الحجر الجيري طاحونة كوريا

- ماليزيا موبايل سحق صانع

- استخدام الحجر المصنع للبيع

- شنغهاي مصنع عملية

- الأسطوانة مطحنة صناعة الاسمنت

- مصنع حجر ، فوب الدولار

- السيليكا

- كسارات الكاو السعر

- مطحنة الكرة مقارنة تكلفة مصنع الاسمنت

- مبدأ عمل رمح

- حيدر أباد الطاحن الفحم الصانع أخذ العينات التحقيق

- mb5x تعليق طاحونة

- كسارة الفك مزيل الغبار

- Mineral Crusher Equipment Manufacturer Philippines

- Cement Industry Equipment Construction

- Manufacturers Rock Crushers

- Barite Grinding Mill Supply And For Sale In Uae

- Crusher Dust Suppliers Brisbane

- Mobile Granite Crushers For Sale Uk

- China Made Mobile Crushers Customer Case

- Block Making Machine For Sale South Africa

- Vdma Roll Neck Bearing For Flattening Mill Roller

- Erpillar Screener Crusher

- Hazards In Mining And Possible Solutions

- Coal Crushers Design Guidelines

- Cement Mill Raymond Mill Vertical Roller

- Mesin Las Miller Big Blue 500

- Whice Cuntry Of Copeer Mine Prosesing In Tanzaniya