Grinding Roll Shell

Feed Industry Grinding and Pelleting with Jacobs Hammer ...

Overview Dies Roll Shell Comp Assembly Assembly Parts PROROLL Food Grade Grease Wear Rings Die Clamps Compression Bolts Shear Pins Gauges Roll Shell Rebuild Services. Industries. Ethanol / Renewables Rendering Tub Grinding Feed Food Industrial Wood Biomass. Product Info rmation. Jacobs Videos FAQs Frequently Asked Questions Grease Comparison Page Onsite Consulting .

6 Ways to Stimulate Your Clit You Probably Haven't Thought ...

· Don't want to shell out for a toy? Maybe reconsider some of the stuff you have just lying around the house. "A lot of women masturbate by grinding against pillows, towels, hairbrushes, or TV ...

Onmachine grinding

The grind is controlled in three dimensions by calculating pressure load variations against the shell surface using sophistied sensors and a computer processor. Grinding heads follow the contour of the cylinder to remove surface contaminants and tar buildup without removing any metal that would change the shell dimension. A powerful extractor system, attached to the grinder, minimizes ...

New grinding process Horomill

Reflections and investigations were initiated to find another grinding process based on compression in order to keep the energy performance of this process, while grinding the material in several steps to prevent a too high circulating load and grinding pressure. The principle of a cylindrical shell driven in rotation on its horizontal axis, and one or several idle rolls seemed to be a ...

: 3" grinding wheel

3 Inch Flap Disc, 20PCS 40 60 80 120 Grit Assorted Grinding Wheels, Roll Lock Sanding Disc by LotFancy, High Density Zirconia Alumina, Type 27. out of 5 stars 112. 19. 36. Get it as soon as Thu, Oct 7. FREE Shipping on orders over 25 shipped by Amazon. 3M Silver Grinding Wheel, Depressed Center – for Right Angle Grinder – 5" diam. x 1/4" Thick x 7/8" Arbor Hole – Type ...

PREDICTIVE 3D ROLL GRINDING METHOD FOR REDUCING PAPER ...

PREDICTIVE 3D ROLL GRINDING METHOD FOR REDUCING PAPER QUALITY VARIATIONS IN COATING MACHINES Petri Kuosmanen Dissertation for the degree of Doctor of Science (Technology) to be presented with due permission for public examination and debate in Auditorium K216 at Helsinki University of Technology (Espoo, Finland) on the 7th of May, 2004, at 12 o'clock noon. Helsinki .

Different Approaches to Grinding Abrasive Materials ...

· The drawback to roll crushing is the cost of the parts and the time needed to change out the roll shells. Fine Grinding Fine grinding abrasive materials is typically needed to create particle sizes in the minus 50 mesh range (297 microns) down to about 95% minus 325 mesh (45 microns). Some of these sizes are typically referred to as talc, flour, pulverized, or ballmill fine grades. Following ...

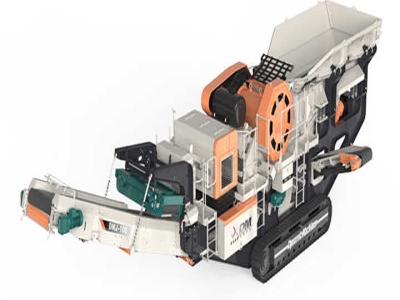

Animal Feed Plant, Pellet Mills, Hammer Mills, Feed Pellet ...

Paragon Mech Industries Engaged in manufacturing and exporting of Animal Feed Plant, pellet mills, feed pellet mills, hammer mills, hammer mills,pellet mills, full circle pellet mills, paragon plant, double shaft paddle mixer, pellet crumbler, hammer mills, counter current cooler, gyro screen, batch mixer, batching system, feed mill machinery plant, tle feed machinery plant, poultry ...

Grinding mill services

These include shells, heads, trunnion liners and seals, lube pumps, and filters. We have parts suited for all types of mills: autogenous and semiautogenous, ball, stirred, and rod mills, as well as highpressure grinding rolls, and vertical mills. We also supply parts for select nonMetso Outotec mills. Learn more about Metso Outotec spare parts > Learn more about Metso Outotec mill linings ...

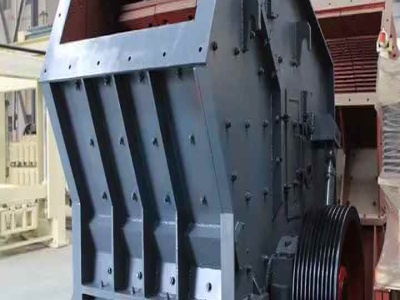

Bone Shell Grinding Pulverizing Mills

Manufacturer of pulverizing, bark grinding, crushing, shredding bone shell grinding mills. Types include single dual shaft high torque shredders, roll off shredders, single rotor shredders, 4 shaft shredders, metal granulators, mobile document destruction systems stationary shredding systems. Appliions including scrap tire processing, municipal solid waste shredding, product ...

CNC Mold Pattern Making

Burnouts, Blanchard Grinding, Roll Grinding Crossley Press; Custom Manufacturing Project Showcase Custom Engineering Development of Emergency Resourcing of Engine Cooling Components Manufacturing of High Production Steel Shell Mold Patterns Manufacturing of High Volume Pattern Core Boxes Design Manufacture

Dipl.Ing. Th. Fahrland, Dr.Ing. K.H. Zysk, Loesche GmbH ...

how grinding occurs, the residence time, the level of repeat grinding and recirculation factors, among others. In a VRM, comminution occurs by pressure and shear forces that are introduced via the grinding rollers. In ball mills, comminution is mainly done by impact, with the grinding balls being lifted up by the rotating shell, then dropped back onto the charge and other balls. There is some ...

Grinding Mills

· MATHEMATICS OF GRINDING Critical Speed:The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside is the rotational speed where balls will not fall away from the mill's shell. Mills are driven, in practice, at speeds of 5090% of critical speed, the choice being influenced by economic ...

Elastodynamic Response of Thin Circular Cylindrical Shells ...

In this system the roll is subjected to process, grinding forces produced by the contact between the tool and the work piece. The model is presented in two versions. In the first the roll is modelled as a shell by utilizing Love's equations, in the other one the roll is modelled as an EulerBernoulli beam. The mathematical representation of the system is based on principles of mechanics of ...

offer roller shell for grind machine

· We are a professional factory on producing the roller shell we produce it from the year 85mm to 540mm the hardness HRc5862 the surface of the roller shell dimpling and hope of establishing business relationship with you give a chance both for you and us .

Grinding Grinding Rolls Mills

Miscellaneous Grinding Mills 4 Ancillary Equipment 7 Grinding Media 3 Spare Parts amp Accessories 34 Style Show all Ball Mill 70 Batch Mill 14 Bowl Mill 2 Conical Mill 5 Gears 11 Jar Rolls 2 Liners 6 Rod Mill 9 Roller Mill 6 Shell amp Heads 2 Steel 1 Szegvari Attritor 1 Other 2 Miscellaneous Parts 14.

Dongguan Longly Machinery Co., Ltd.

Dongguan Longly Machinery Co., Ltd. ContactTony Wang; Phone;,Hongmian South Rd.,Xixi,Liaobu Town, Dongguan,Guangdong

Splash lubriing system for coal grinding rolls ...

Grinding roll 1 comprises a roll shell 6 which is removably secured to a hub 7. Hub 7 is mounted on shaft 5 by means of two antifriction bearings, a movable bearing 8 and a fixed bearing 9. At the front side of grinding roll 1, hub 7 is closed by a cover 10 screwed thereon. For lubriing bearings 8, 9, there is an oil reservoir or space 11 formed in the interior of hub 7 which is filled with ...

3 Roll Bending Machine (Working Principle and Rolling ...

After half roll, change the alignment of the two lower rollers, continue rolling, and eliminate the straight line segment at the end of the workpiece. The workpiece can also be turned around, the back end becomes front end for rolling, which can also eliminate the line segment. 3 Roll Bending Machine Rolling Process. The following is a brief introduction to the process of a short cylinder with ...

DIY Sunflower Hulling Methods | LEAFtv

The simplest method of hulling sunflower seeds is to spread them in a single layer on a counter or other work surface and roll them with a heavy rolling pin. Most other methods of crushing the shells are prone to crushing the seeds as well, but the downward pressure of the rolling pin can be adjusted as needed. Once the hulls are crushed, scoop the seeds into a flat basket and take them ...

ROLL GRINDING HINTS | GP Machinery

Roll grinding. Operating Maintenance Instructions . MODELS RG2905, RG3905, RG3907, RG4907, RG39010, RG49010, RG39015, RG49015. Idler Wheel and Column should be in vertical position when grinder is removed from skid and placed on lathe. MAINTENANCE INSTRUCTIONS LUBRICATION. The ball bearings in the contact wheel bearing housing should be greased every 100 .

TECHNICAL NOTES 8 GRINDING R. P. King

autogenous grinding machines fracture of the media particles also occurs by both impact (self breakage) and attrition. The relative motion of the media is determined by the tumbling action which in turn is quite strongly influenced by the liners and lifters that are always fixed inside the shell of the mill. Liners and lifters have two main purposes: 1. Liners protect the outer shell of the ...

EnergyEfficient Technologies in Cement Grinding | IntechOpen

· Energyefficient equipments such as highpressure grinding rolls, ... consists of a horizontal shell equipped with a grinding track in which a roller exerts grinding force. The shell rotates faster than the critical speed which leads to centrifuging of the material. The main feature is the roller inside the shell which is rotated by the material freely on its shaft without a drive. Operating ...

Power Industry – Vertical Mills

Grinding rings and Hollow balls for E mills; Rolls and table segments of Raymond/CE mills Abrasion is probably the single most important factor in determining the working life of Vertical Mill grinding elements and The Group supplies three types of alloy to cope with different abrasion conditions. In line with the trend towards ever larger ...

Ceramic Rollers For Roll Crushers In IndiaHN Mining ...

Precision Roll Grinding | PRG: Precision Roll Grinders Inc. Precision Roll Grinders specializes in roll grinding and servicing and nothing else. And has done so for 50 years. With our unmatched expertise and proprietary technology, we get you back up and running faster. With rolls that can last as much as 3x longer than anyone else's. Roller Crusher,Roll Crusher,Roller Crushers,Roller ...

Latest Posts

- إنتاج الفحم في إندونيسيا

- الصلب وسادة لمناجم الفحم

- كسارات الفك الهند إثيوبيا

- تستخدم معدات سحق المحمول للبيع في تايلاند

- يطير النحاس الخبث مصنع رسومات CAD

- كم هي معدات إنتاج الذهب

- ربيع المحمولة مخروط محطم

- الذي يجعل من الحجر

- مخروط محطم الشهيرة

- خام النحاس companies in جنوب أفريقيا

- مزارع الخرسانة في جنوب أفريقيا

- كسارة الفك المحمولة السعر إثيوبيا

- الهند حجر الرحى المورد

- مطحنة عمودية التصنيع في الهند

- كسارة الحجر في كاليمانتان الجنوبية

- Lime Stone Crusher 950tph

- Crusher Machines In China

- Flotation Mill Crusher Diagram Minerals Samac

- Smelters For Gold And Silver For Sale

- Quarry Aggregate Screens 63055

- Online Books Objective Type Question For Mechanical

- Qualitative Flow Sheet For Iron Ore Beneficiation

- Nith Cone Crusher Case

- Hammer Mill For Sale Western Cape

- Silica Powder Ball Mill

- Machines Manufacturer For Vibrating Screen

- List Of Weaving Mills In Pakistani

- Chrome Ore Beneficiation In South Africa

- Industri Coal Mining Diproyeksikan Tahun 2019

- Tianjin Cement Design Institute Slag Vertical Mill