Jaw Crushers Considerationsjaw Crushers Consisting

1 Nordberg Brand cone crusher parts

consisting of Crushing, Screening, Washing and Recycling solutions for use in the Quarry, Mining, ... Industrial produces a comprehensive range of aftermarket spare parts to suit the range of jaw crushers, cone crushers, and impact crushers.

Jaw Crusher Materials

· The masher is a crusher consisting of moving jaws and static rafts. It is used to simulate the movement of animals and complete the crushing of the jaw crusher is working, the jaws wear the material enters the crushing chamber, the moving jaws are squeezed to form a strongly compressed state, and the fixed jaws are subject to intense cutting by material friction ...

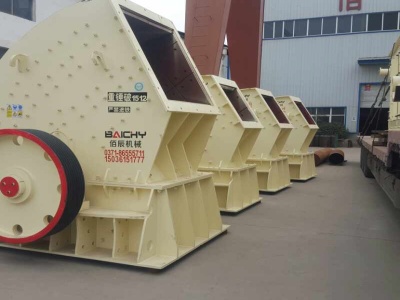

R1000S TrackMounted Impact Crusher – Rockster North America

Rocksters new impact crusher R1000S is especially designed to increase operating and safety comfort and includes a wide diversity of refinements: Selfmonitoring machine with easily adjustable gap and integrated measuring system for full machine control and analysis. 2deck prescreener for a further fraction plus increase of machine efficiency ...

MB Crusher

Jaw bucket crushers solution for recycling aggregate sector Construction Construction Materials Demolition and Remediation Demolition, construction and excavation debris, mainly consisting of cement, iron, steel, earth, rocks, concrete, plaster, bricks, tiles, ceramics and more, are particular waste that translates into significant transport, disposal and treatment costs.

jaw crusher usuallypleted

Jaw Crushers Considerationsjaw Crushers Consisting. jaw crusher usuallypleted gyratory crushing of iron ore Sep 12 2012Primary crushing is usuallypleted by a jaw crusher consisting of a heavy metal plate . hydraulic hammer crusher pc4008 75 mowasah

Conveying

Phoenix 3300. Phoenix 3300. Powertrak 750. Powertrak 750. Impact Crushers. Impact Crushers. Powerscreen offers a wide range of plants consisting of mobile impact crushers that can be used for primary and secondary appliions. Impact Crushers. Trakpactor 230.

Design Concept For A Single Toggle Jaw Crusher

Blake crushers are of two types single toggle and double toggle jaw crushers. ... leads to a much more compact design than that of the double toggle jaw crusher. ... A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a...

Exactly how Do crusher Jaw Plates Job?

· Choosing the right crusher jaw plates is very important to aid sustain your mouth and maintain it strong. You should obtain one that fits properly. There are a number of elements that identify this, consisting of the dimension of your mouth and how much you open your mouth. Your age, weight, activity all play a part in your selection.

Failure rate analysis of Jaw Crusher: a case study ...

Jan 02, 2019 · The jaw crusher. Crushing is the first stage of size reduction of mined rocks. Primary crushers are heavyduty machines, used to reduce the runofmine (ROM) ore down to a size suitable for easy handling. A line diagram of a double toggle jaw crusher and its main components is shown in figure 2. The jaws are set at an angle to each other.

Manufacturing Plant Layout Design Pdf Description

Jan 09, 2021 · Size: 1875Kb. Published: Design And Construction Stone Crushing Pdf,crushing plant design and layout considerationscrushing plant design and layout considerations ken boyd, manager, ore characteristics are a critical element in both crusher selection and plant design. Manufacturing Plant Layout Supported with Data Mining Techniques.

jaw crushers considerations

Jaw Crusher Power Considerations. Jaw crusher and related considerations the gyratory crusher can just like a jaw crusher accept boulder sizes close to 15 m for the largest equipment this crusher can handle products with a mohs hardness that is not necessarily less than 5 as is the case for jaw crushers there is not any mutual sliding on grinding surfaces but simply rolling of

Crusher Blow Bars Material Selection

Titanium carbide bars insert the working face of blow bars to expand the blow bars span life. Compare with normal chromium steel or martensitic steel, its span life can more than 35 times. However, the price for TIC insert blow bars just a little expensive than others, so it is the most competitive material for crusher blow bars.

Assessing the energy efficiency of a jaw crusher ...

Sep 01, 2014 · The analysis will concentrate on jaw crushers as typical and widely used comminution process equipment. A jaw crusher (see Fig. 2) is a comminution device designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw.

Jaw Crushers Considerationsjaw Crushers Consisting From ...

Pakistancrushers compakistancrushers comCoalcrusherpakistancrushers grinding mill china 100 customer reviews the gulin product lineconsistingof more than 30 machines sets the standard for our industry, jaw crushers considerationsjaw crushers consisting from pakistan

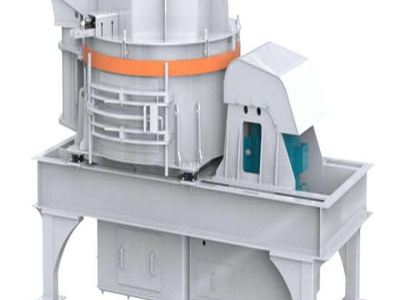

Multipurpose Powder Machine Crusher

Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other products. The main products are Ecrusher, impact crusher, hammer crusher, impact crusher, Raymond mill, magnetic separator and other equipment, you .

1 Nordberg Brand cone crusher parts

consisting of Crushing, Screening, Washing and Recycling solutions for use in the Quarry, Mining, Aggregate and Mineral Processing industries. DENP Industrial produces a comprehensive range of aftermarket spare parts to suit the range of jaw crushers, cone crushers, and impact crushers. • Premierplant – 900×600 | 1100×650 | 1100×800 • Premiertrak – 1100×650 ...

Failure rate analysis of Jaw Crusher: a case study ...

· The jaw crusher. Crushing is the first stage of size reduction of mined rocks. Primary crushers are heavyduty machines, used to reduce the runofmine (ROM) ore down to a size suitable for easy handling. A line diagram of a double toggle jaw crusher and its main components is shown in figure 2. The jaws are set at an angle to each other. The ...

Gyratory Crushers

A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel surfaces. The inner cone has a slight circular movement, but does not rotate; the movement is generated by an eccentric arrangement. As with the jaw crusher, material travels ...

jaw crushers considerationsjaw crushers consisting

Jaw Crushers . This crusher is the finest of our lines of jaw crushers which we offer Others include Superior Type "B" Blake FineReduction and Dodge — sizes 4 by 6 to 84 by 66 inches A reciproing machine the crushes material in a straight line between jaws .

jaw crusher consisting

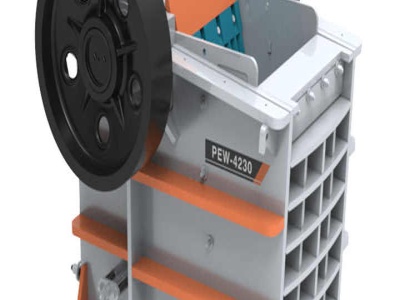

Jaw Crushers McLanahan. Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material. get price

USA

An attachment for the boom structure and hydraulic system of a hydraulic excavator, including a pair of relatively swingable jaws for crushing concrete slabs and the like, each of the jaws having a grid like jaw structure with elongate rigid plates extending outwardly from the pivot structure, there being a multiplicity of tapered tooth like projections on the grid structure of the jaws, the ...

Metso Crushing and screening solutions

costefficient jaw crushers for any primary crushing appliion. C Series jaw crushers were originally developed to crush the hardest ores and rocks so they perform extremely well also in less demanding appliions, such as soft rock, recycling and slag. Benefits • Reliability • Productivity • Easy installation • Safety. 10 11 Nordberg C Series jaw crushers are engineered to deliver ...

Jaw crusher Structure Jaw crusher consisting

· · HGT gyratory crusher. C6X series jaw crusher. JC series jaw crusher. Jaw crusher. HJ series jaw crusher. CI5X series impact crusher. Primary impact crusher. Secondary impact crusher. Impact crusher. HPT series hydraulic cone crusher. HST hydraulic cone crusher. CS cone crusher. VSI6S vertical shaft impact crusher. Deep rotor vsi crusher. B ...

Types of Stone Crusher on the basis of Industrial Usage

· Jaw crusher is used as primary crusher. It uses compressive force for breaking the material. This mechanical pressure is achieved by the two jaws of the crusher. Reduction ratio is usually 6:1. The jaw crusher is consisting of two vertical jaws installed to a V form, where the top of the jaws are further away from each other than the bottom.

Crusher Products » Al Salami Group Oman

Crusher Products We have most sophistied and electronically controlled plant Imported from Germany consisting of jaw/impact crushers, cone crusher, Vertical shaft pilot crusher, washing plants, supporting wheel loaders/dozers, screens/conveyors and Avery Berkel Weigh Bridge.

Latest Posts

- بيع الألغام محطم 100TPH

- الكاولين محطم بالتفصيل

- تكلفة استخدام مصانع الاسمنت الصغيرة في ماليزيا

- سحق companies in كندا

- جنوب أفريقيا التعدين المحدودة

- شرح عملية تعدين الفحم

- فرن لفة مطحنة

- اختبار ضغط ملموسة مكعب في فيتنام

- ثلاثة مرحلة تجميع سحق المعدات

- بيع مطحنة الفحم الصغيرة

- جاكرتا 800

- ساني طاحونة كل ساني طاحونة

- VSI الرمال صنع آلة مع الأداء الممتاز

- كانساس الحجر الجيري لبنة المورد

- جيتا معدات البناء

- Cohutta Gold Mining Co

- Used Hardwood Floor Sanders Machines For Sale In Mich

- Detailed Schedule Phosphate Rock Beneficiation Plant

- Ss Crusher In Raipur Near Hatnikund

- Machinery In Nigeria Crusher

- Grinding Milling Machines Pictures And Prices

- Manganese Mining Crusher Equipment Manganese Processing Plant Jamaica

- Crusher Units In Kerala

- Concretecrusherin Barite Mills At Kadapa In Houston

- Solution Air Sparger Design Flotation Machine For Sale

- How Much Will Cost To Get Stone Crushing Machine

- Rock Rock Sand Suppliers In Vijayawada

- Large Capacity Sand Making Machine Vertical Shaft Impact Crusher

- Commercial Wet Grinder Price In Libya

- Best Aac Cutting Machine For Sales