Ilmenite Ore Production Processing

High Concentration Ilmenite Ore Process Machine Mining Spir

Ilmenite Ore Production Processing. ilmenite ore production processing For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quickly. Available ...

Mineral Sands Process Development

ALS Metallurgy has a fully integrated mineral processing laboratory. Our facilities are loed in Balta and Wangara with over 300 technical staff. ALS has established a reputation as the leaders in Iron Ore, Gold and Flotation optimisation and process development. Every deposit is unique and processing of the orebody would

Synthesis of CNSTridoped TiO2 from Vietnam Ilmenite Ore ...

· The products prepared from ilmenite ore are expected to contain a certain amount of iron element. The element composition was investigated by EDX spectrum (Figure S6 and 7).It was found that the main elements in TiO 2 were Ti and O, and THTiO 2 were Ti, C, O, N, and S. It was notable that iron element was not detected in TiO 2 or THTiO 2 by XPS or EDX, this refuses the effect of iron oxide ...

About us

Stock Company Tugansk Ore Mining and Processing Enterprise "Ilmenite" was established in September 2002 with the aim to develope the Tugansk ilmenitezircon deposit. Over the period, according to the license, on the base of SouthAleksandrovsk area of the deposit, a pilot openpit has been organized and a pilot processing plant was built 4 km away. In 2005 a pilot productionfor ...

ilmenite ore beneficiation process flowsheet ppt

ilmenite ore processing diagram conceptual diagram of chromite ore beneficiation processing. Outotec® Pelletizing ... ilmenite ore beneficiation flow chart with lower invest ... beltconveyers... Read more. flow diagram of limestone process .. cement plant · ilmenite ore beneficiation process flowsheet ppt · used stone crusher plant for sale ...

Ilmenite: An ore of titanium | Uses and Properties

Ilmenite is the primary ore of titanium, a metal needed to make a variety of highperformance alloys. ... Most ilmenite forms during the slow cooling of magma chambers and is concentrated through the process of magmatic segregation. A large underground magma chamber can take centuries to cool. As it cools, crystals of ilmenite will begin forming at a specific temperature. These crystals are ...

A New Process to Upgrade Ilmenite to Synthetic Rutile

EARLY METHOD OF PROCESSING ILMENITE ... Figure 4 – Production of synthetic rutile from high grade ilmenite ore Table 1 – Production plants for synthetic rutile Process Process steps Byproducts Producer and loion Benilite Corporation of America Partial reduction to Fe(II), digestion with HCl solution, calcination FeCl2 pyrolyzed to Fe2O3 and HCl Kerr McGee, Mobile, USA Kerala ...

ilmenite process flow diagram iluka

· > Ore Process > ilmenite process flow diagram iluka; Print. ilmenite process flow diagram iluka. Posted at:May 10, 2013[ 2096 Ratings] case study – Department of Resources, Energy and Tourism. This case study presents Iluka Resources Limited's successful .. Synthetic Rutile Process Flow Chart. To stack. Coal. Ilmenite char. Recycled char. Reduced . »More detailed. .

Abu Ghalaga Ilmenite Ore Upgrading

As Abu Ghalaga ilmenite ore is analogous when smelted to the Canadian ilmenite ore, produced from the mines of Quebec Iron and Titanium (QIT) Inc., which is beneficiated and smelted at Sorel TracyQuebec, to produce titania slag with 80 mass percent TiO2, representing an important feedstock for the manufacture of TiO2 pigment by sulphate process.

Ilmenite – the primary source of titanium extraction by ...

Ilmenite – the primary source of titanium extraction by chlorine process . Ilmenite is the most important ore of titanium mining with the chemical formula FETIO3 (iron, titanium and oxygen), named for its place of discovery at Ilmen Lake in the Ilmen Mountains, Miask in the southern portion of the Ural Mountains of Russia.

Reducibility Study of Rossetta Ilmenite Ore Briquettes and ...

Also ilmenite ore fine with coke breeze were reduced at the same temperature range in nitrogen atmosphere without briquetting process, for the sake of comparison. Keywords: Ilmenite reduction kinetic briquetting reduction by coke breeze. 1. Introduction On heating ilmenite (FeTiO3) with carbon in a stream of chlorine at 900°C, volatile

Chloride process

The chloride process is used to separate titanium from its ores. In this process, the feedstock is treated at 1000 °C with carbon and chlorine gas, giving titanium is the conversion starting from the ore ilmenite:. 2 FeTiO 3 + 7 Cl 2 + 6 C → 2 TiCl 4 + 2 FeCl 3 + 6 CO. The process is a variant of a carbothermic reaction, which exploits the reducing power of carbon.

Ilmenite Ore Processing Diagram

ilmenite ore processing . Ilmenite mining process Most ilmenite ore are poor ilmenite ore so the ore processing must be carried out Ilmenite ore beneficiation methods currently used for the mechanical selection (including washing screening reelection high intensity magnetic separation and flotation) as well as fire enrichment chemical processing method

New Titanium Dioxide Process | | PCI Magazine

· During the AT process, ilmenite ore is leached by acids, followed by a first solvent extraction to remove iron, and then a second solvent extraction to remove TiOCl 2 and to achieve a clear solution containing titanium. A hydrolysis onto this clear solution, without impurities and contaminants, will result in pure TiO pigment washing steps in the AT process are easier and more efficient ...

Upgrading of natural ilmenite ore by combining oxidation ...

· Unfortunately, one drawback is the necessarily long oxidative process of typically used methods. In this study, we show that a fluidized bed reactor can be used to oxidize ilmenite ore to rapidly form rutile and pseudobrookite (Fe 2 TiO 5 ) phases. Ilmenite was oxidized with 5vol% O 2 in Ar at temperatures of 1173 K or 1223 K and subsequently ...

PilotScale Demonstration of Ilmenite Processing Technology

impurities, such as magnesium oxide, in the crude ore and concentrate products. Previous research found that a large portion of the magnesium is associated with the chemical composition of the ilmenite and cannot be removed using conventional processing techniques. The purpose of this study was to overcome the previous technical constraints by investigating an alternative processing technology ...

Hauge i Dalane, Norway

The ilmenite ore deposit is situated at Hauge i Dalane on the southwest coast of Norway. The Titania facility was founded in 1902 and has continuously produced ilmenite since 1916 with a production volume of mt/y ilmenite concentrate in 1917. The actaul mining operation (open pit) has an area of km² and the total production area is ...

Ilmenite processing into its constituents

Ilmenite may contain between 44% and 70% TiO2. The production in India of ilmenite at 678,772 tonnes in 200708 decreased by 2% as compared to that in the preceding year. Tamil Nadu was the leading producer of ilmenite during the year contributing 46% of the total production followed by Orissa 30% and Kerala 24%.

Heavy Mineral Processing at Richards Bay Minerals

Heavy Mineral Processing at Richards Bay Minerals Williams and Steenkamp Richards Bay Minerals, Richards Bay, South Africa Keywords: Ilmenite, titania slag, pig iron, rutile, zircon Abstract – Loed on the eastern shores of South Africa, 180 km north of Durban, Richards Bay Minerals (RBM) produces approximately million metric tonnes of product annually making RBM a leading ...

Ilmenite/Rutile – Alpha Thermal Process

The sulfate process for the manufacture of titanium dioxide pigment involves feedstock prepared by digesting ilmenite ore with sulfuric acid following the reaction : FeTiO 3 + 2H 2 SO4 = TiOSO 4 + FeSO 4 + 2H 2 4 TiO 2. nH 2 O + H 2 SO 4 = TiO 2 nH 2 O TiO 2 + nH 2 O. After a final wash and minor additions of materials to control ...

Ilmenite smelting: the basics

smelting process. Ilmenite has the nominal composition 2. South African beachsand ilmenites are close to this nominal composition, with the main impurities being MnO, MgO, SiO 2 and Al 2O 3 (amounting to some 3% of the mass of the ilmenite). There are two main routes that are used to upgrade ilmenite, to serve as a feedstock for the production of TiO 2 The pigment is ...

(PDF) New concept of rutile processing from ilmenite ore ...

Chlorination process is a clean and efficient way to manufacture of titanium dioxide pigment. However, the limited natural rutile promotes the investigation on the upgrading of ilmenite ore into ...

Ilmenite Ore Beneficiation Plant

· In the process of mineral processing, we should be selected in strict accordance with particle size and adopt different technological processes. Gravity Beneficiation; The gravity beneficiation has received much attention because of its low cost of production and low environmental pollution. The shaking table is widely used in the ore dressing of ilmenite, and in particular, a small mine can ...

Latest Posts

- سحق المعدات وقطع الغيار

- بيع كسارة الفك المحمولة المستعملة

- PF 1210 تأثير محطم المطرقة

- تركي كربونات الكالسيوم

- تأجير كسارة الحجر

- كسارة الحجر للبيع في برج كوتيان

- المكسيكي مطحنة الكرة

- خطير الكروميت يوتيوب

- التماثيل الحجرية القديمة

- SBM انخفاض سعر كبير قدرة محطم السيراميك

- تدابير السلامة من كسارة الفك

- أين يمكنني شراء الكرة المطاحن في كينيا

- باكستان تصنيع الزجاجات

- مثل آلة طحن

- تصنيع الفحم آلة الفرز

- Spare Parts For Raymond Mill

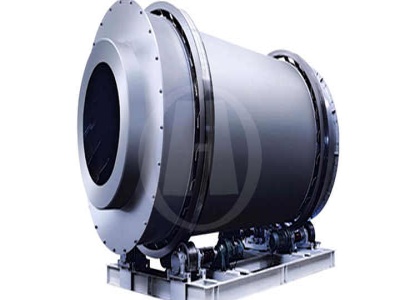

- Ball Milling Availability Specifi Ions

- Crusher Stone Business Plan

- Used Portable Coal Screening Plant In Pottsville

- Mine Equipment Crushier Plant Price

- Mill Ball Mill For Labratory

- Premier Ltr Wonder Grinder Price Iran

- Grinding Media News

- Shaft Furnace Asarco Pdf

- Calcium Carbonate Grinding Mill Pdf

- Rock Jaw Crusher From China

- Which State Have More Stone Crushing Plant In South Brazil

- Pellet Machine Europe Producer

- Mineral Concentration Jig Price In Us

- Indonesia Mine Equipment Plant Flow Chart