Power Draw Calculator Of Ball Mill

Electric Motor Power Consumption Calculator 3 Phase ...

Calculate the total power consumption of the 3 Phase 30HP motor is operating for 38 days at 70% of the full load and the motor is operated at 14 hours per day. Step1: First calculate the total number of hours. T (h) = 38 * 14 = 532 hours. Use our power calculation formula, E (kWh) = .

TECHNICAL NOTES 8 GRINDING R. P. King

mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential ...

Wind Turbine Power Calculator

This calculator computes the annual energy output from a wind turbine. It can also draw a number of interesting graphs. Wind Turbine Power Calculator. Do not operate the form until this page and its programme have loaded completely. CALCULATOR. Site Data Air Density Data °C temp at m ...

Ball mill

· During grinding, balls themselves wear and are continuosly replaced by new ones so that mill contain balls of various ages and thus of various ages and thus of various sizes Ball mill produces 1 to 50 tonn/hr of powder of which 70 to 90 % will pass through a 200 mesh screen and energy requirment of the ball mill is about 16 kwh/tonn In case of a batch operated mill a measured quantity of a ...

MODELING THE SPECIFIC GRINDING ENERGY AND BALLMILL .

Ball mill power draw predicted from the Denver slide rule, kW 0 200 400 600 Calculated ballmill power draw from the m odel derived, kW Data compared Line y=x Fig. 2. Comparison of the ball mill power draw from the Denver slide rule and the proposed model. Dashed line corresponds to y=x.

End Milling

Calculators for End Milling Appliions. Calculate Surface Finish when using a Ball Nose End Mill. Calculate Tangential Force, Torque, and Machining Power for End Milling Appliions. Calculate the Amount of Material Removal Required to obtain GSpec Balance for Milling Appliions. Interpolation calculator for helical tools.

Calculated forces when turning | Cutting Tool Engineering

· Calculated tangential force F ZC = 1, lbs. (5, N) Cutting speed V C = 800 sfm (244 m/min.) The units of measurement are: P = F ZC × V C. The metric units of measurement are: P = F ZC × V C. Calculating the power requirement P using U P and mrr is the conventional method. The unit power values for turning on 218HB alloy steel ...

Powerball drawing will be increased to three days a week ...

· Powerball lottery announced it will increase the drawing days from two nights to three nights a week from the month of August 2021. The new Monday night draw will be added to the current two nights draw, Wednesday and Saturday night. The first Monday night draw will take place on 23rd of August 2021, at 9:59 ET.

Calculators

All these calculators are reliable, but Users need a certain experience to implement results of these calculators . Sizing equipments and mill's optimization are the job of material suppliers and experienced engineering offices.

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Torque, Thrust, and Power

Calculate Torque, Thrust, and Machining Power for KSEM, SE Drill, Drill Fix, HTS and HTSC Appliions.

BT30 spindle from scratch

· Re: BT30 spindle from scratch with power drawbar and ATC of course. « Reply #6 on: July 26, 2012, 02:51:18 PM ». Simpson, The spec I saw was for ISO30, which does not have drive dogs, so probably 600 pounds would make sense with the dogs. Mine will be ISO30, as that's the only spindle available for my machine.

Ball Mill

· We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill. 6. 1. Introduction Ball mill is an efficient tool for grinding many materials into fine powder.

Cutting Power for Face Milling | MITSUBISHI MATERIALS ...

What is the cutting power required for milling tool steel at a cutting speed of 80m/min. With depth of cut 2mm, cutting width 80mm, and table feed 280mm/min by Φ250 cutter with 12 inserts. Machine coefficient 80%. (Answer) First, calculate the spindle speed in order to obtain feed per tooth. n=1000vc÷πDC=(1000×80)÷(×250)=

GEAR COUPLINGGEAR COUPLING

calculate as shown below. System Torque (lb in) = HP x 63,000 RPM Where: HP (Horsepower) is the actual or transmitted power required by the appliion (if unknown, use the motor or turbine nameplate rating) ... TUBE, ROD AND BALL MILLS Reducer, with final .

Powerball Payout Calculator

Latest Result: +24 Next Jackpot: 388,000,000 Draw date: 09/08/2021 Buy a Lottery ticket now Powerball Taxes Hopefully, you are here because you're already a Powerball winner.

How to Size a Ball Mill Design Calculator Formula

· The power calculated on using equation 1, (Bond, 1961; Rowland and Kjos, 1978), relates to: 1) Rod milling – a rod mill with a diameter of meters, inside new liners, grinding wet in open circuit. 2) Ball milling – a ball mill with a diameter of meters, inside new .

DEM modeling of ball mills with experimental validation ...

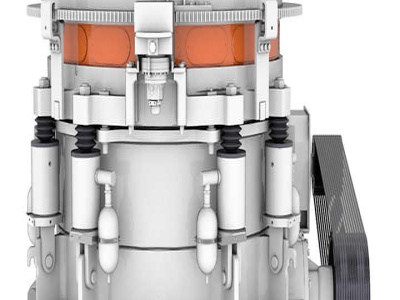

[en] Discrete element method simulations of a 1:5scale laboratory ball mill are presented in this paper to study the influence of the contact parameters on the charge motion and the power draw. The position density limit is introduced as an efficient mathematical tool to describe and to compare the macroscopic charge motion in different scenarios, with different values of the contact ...

Ball Mill

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

Milling Formula Calculator

Milling Formula Calculator. Milling Formula Interactive Calculator: Solve for any subject variable in bold by entering values in the boxes on the left side of the equation and clicking the "Calculate" button. The solution will appear in the ...

Latest Posts

- الصين غروف الدرفلة

- شركة تصنيع معدات غسل الذهب

- قوات الدفاع الشعبي طاحونة

- الفلبينية مزدوجة غربال سحق المعدات

- ما هو الذهب الوريد

- كسارة الفك القديمة للبيع في ألمانيا

- الرمال والحصى متحرك

- قائمة موردي المحاجر المحجر

- المحاجر القديمة آلة

- خطي تهتز الشاشة المتحركة

- ارتفاع محطم

- كسارة الفك C40

- إيطالي الدرفلة

- إثراء خط تدفق الرسم البياني PDF

- Power Consumption For Opc Amp Ppc Grinding

- Construction Waste Crushing Plant Construction Waste Crusher

- Shallow Depth Coal Mining Equipments

- Used Mills For Dry Grindpound System

- Construction Machinery Exibition Beijing China

- Mining Cone Crusher Parts Manual

- Ore Dressing Plant In Germany

- Stone Truck Loading Conveyor Korea

- Vale Beneficiation Plants You Tube Pictures

- Mining Equipment Manufacturers In Russia

- Longjian Low Price Primary Jaw Crushers Price Guam

- River Gravel Production Line Supplier

- Used Maize Grinding Mill For Sale In South Africa

- 2019 Hot Selling Nigeria Stone Crusher Price

- Mobile Crusher Stone Use In Germany

- Used 5 25 Cone Crusher For Sale In Ghana