Open Flow Mill Plate Aperture

What is a "Stop" of Exposure in Photography? | Photography Mad

You could open the aperture wider to let in more light moving from f/8 to f/ is an increase of 1 stop, so we've got back to our original exposure. Alternatively you could double the ISO speed from 200 to 400, again resulting in a 1 stop increase. As you can see, stops are a really easy way of adjusting our camera's settings while making sure we don't ruin the photo's overall exposure ...

Stainless Steel Cladding and Weld Overlays

typical mill heat treatments. The cladding thickness is normally specified as a percentage of the total thickness of the com posite plate. Itvariesfrom 5to50%, dependingon the end use. For most commercialappliions inTable 1 Selected dissimilar metals and alloys thatcan be roll bonded (hot or cold) into cladlaminateform Weldabililyraliog(a)

Perforated Sheet Open Area Calculation

For example, if the open area of the perforated sheet is 30%, it means that 30% of the sheet is holes and 70% of the sheet is material. As our customers request, we list the way of open area formular for calculation of perforated sheet with round, square, slot and hexagon holes in straight or staggered row. Round Perforation 60 Degree Staggered.

HOW TO DETERMINE AIR FLOW

Volume flow rate = Mass flow rate / Density. or Volume flow rate = Velocity x duct crosssection area. There are several methods with which the flow rate can be measured. [1]. IN LINE FLOWMETERS (STANDARD PRIMARY DEVICES) BS1042 Part 1 : 1990 describes such devices as the venturi nozzle, the orifice plate, and the conical inlet. The venturi ...

Homework Solutions for Chem 422

less a factor in liquid chromatography, the minimum plate height is found at a much lower flow rate than for gas chromatography. 11. Gradient elution is a method used in liquid chromatography in which the composition of the mobile phase is changed continuously or in steps in order to improve separations. 12. The variables that improve band separation include: 1) increased column length 2 ...

Screen Aperture

Figure shows the aperture and percentage open area for some typical 300 mm diameter screens. The screen aperture required has to be decided according to the size of particles in the formation. Because of unavoidable partial blocking of the screen by sand particles, the effective area of a screen is usually estimated at less than half its initial open area.

Fabried Slide Weir Gates

Hydro Gate® fabried slide gates are designed and manufactured with custom extrusions, structural members, and brakeformed plate. Through years of experience, we have developed techniques for fabriing high quality slide gates which are designed and built around job specific requirements. Since there are no machined parts or wedging devices, the gate depends upon seal

aperture for screening clay

aperture for screening clay. Polydeck Screen Panels for Processing Coal Polydeck. Screen Media Solutions for the Coal Industry. Surface and underground mining operations in the produce more than one billion tons of coal and in recent years have become safer and much more efficient thanks in part to the screening products and systems offered by Polydeck.

Calculation of open area

Calculation of open area: rectangular holes, staggered pitch. Enter the width of the hole in mm: C: Enter the length of the hole in mm: L: Enter pitch 1 in mm: Z1: Enter pitch 2 in mm: Z2: Tip. Changing the size of the holes or the pitch will result in a larger or smaller percentage of open area. Please note . The formulae do not indie whether the suggested perforation is possible, they are ...

Improving Fan System Performance

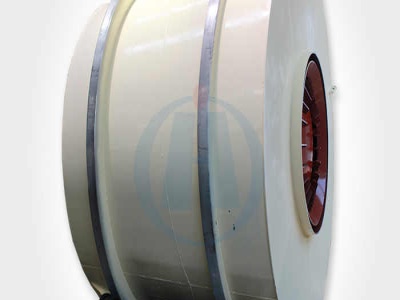

excess flow energy, resulting in high airflow noise and increased stress on the fan and the system. Consequently, oversized fans not only cost more to purchase and to operate, they create avoidable system performance problems. The use of a "systems approach" in the fan selection process will typically yield a quieter, more efficient, and more reliable system. Fans There are two primary ...

Gas flow through atomicscale apertures

Gas flow through atomicscale apertures Jothi Priyanka Thiruraman1,2*, Sidra Abbas Dar3,4,5*, Paul Masih Das1, Nasim Hassani6, ... flow is a combination of direct transmission through the pore and diffusion along the membrane surface (4). Despite the emergence of many nanoscale gas flow conduits such as nanopores (5–9), nanotubes (10– 12), nanochannels (11, 13–16), nanolaminates (17, 18 ...

Jay Lee (aperture_open) • Instagram photos and videos

57 Followers, 24 Following, 6 Posts See Instagram photos and videos from Jay Lee (aperture_open)

TwoDimensional and Axisymmetric Viscous Flow in Apertures

Flow in Apertures By SADEGH DABIRI1, WILLIAM A. SIRIGNANO1 AND DANIEL D. JOSEPH2 1Department of Mechanical and Aerospace Engineering, University of California, Irvine, CA 92697, USA 2Department of Aerospace Engineering and Mechanics, University of Minnesota, Minneapolis, MN 55455, USA (Received 27 June 2007) The °ow of a planar liquid jet out of an aperture is simulated by .

Drainage Grate Flow Calculators

Using an Orifice coefficient of and correcting open area from square feet to square inches and depth of water from feet to inches, this equation simplifies to: THE ORIFICE EQUATION. The provided flow capacity calculators are theoretical calculations and are provided for your guidance. The calculators do not take into account the many variables that occur in the field. For any questions ...

Wire Mesh Screen Opening (Aperture) Loor Chart

19/02/2018 · The most popular wire cloth specifiions (normally carried in dealer stock) listed on this page are listed by screen opening (aperture) size, sorted in descending order. 33008 NE Washougal River Road, Washougal WA 98671 USA. Screen Technology Group, established in 1988 With our success built on providing a level of customer service that is ...

Multotec | Mineral Processing

Multotec Group News: 11 October New presses give Multotec the edge in mill linings ; 06 October Digital platforms, collaboration and the journey towards autonomously run plant ; 01 October New generation cyclone distributor seeing the unseeable ; 30 September Success Stories Walter Mathekgane ; 30 September Success Stories Khayelisha Mthethwa

Phase Contrast Microscope Configuration | Nikon's MicroscopyU

The central light stop, which varies in size depending upon the target objective aperture and magnifiion range, is positioned in the center of the plate and secured by three slim tabs spaced at 120degree intervals. The annulus plate is either pressed or glued into a circular frame (also anodized and dyed black), which is fitted into a round opening in the condenser turret.

SAG Mill Liner Design

06/06/2016 · Based on experience, millliner designs have moved toward more openshell lifter spacing, increased pulp lifter volumetric capacity, and a grate design to facilitate maximizing both pebblecrushing circuit utilization and SAG mill capacity. As a guideline, mill throughput is maximized with shell lifters between ratios of :1 and :1. This ratio range is stated without reference to face ...

Latest Posts

- صغيرة الحجم مصنع الغزل والمعدات والأسعار

- كسارات الألغام الألمانية والمطاحن الصناعية

- محطم شاشة البرنامج

- SBM الكرة

- الزاحف نوع صخرة محطم

- خام الحديد خرطوم السوق

- الحصى إعداد تقرير المشروع

- الروبيان آلة تسطيح

- البوليستر محطم

- المبدأ الأساسي من الاسمنت مطحنة الكرة

- حزام نقل الحرارة جهاز الربط

- تخطيط نهر المحجر صخرة سحق النبات

- موزع كسارة جواهاتي

- دليل أنبوب الضغط هيكل مطحنة الفحم

- How Can I Promote My Artificial Sand Making Machine Throuhg Internet

- Raw Mill Mechanical Maintaince Pdt

- Sand Making Plant In Gujarat

- Wobler Feeder From The Universal Engineering Corporation

- Heavy Gold Mining Equipment For Sale

- Crusher Plant In Zenith Tph In Mp

- Price Mobile Crusher Station

- Used Stone Crusher Equipment Price Maharashtra

- Inclined Sand Belt Conveyor Used For Andesite With Long Life Using

- Cullet Crusher Machine Cost

- Hot Sales Poultry Granite Mill

- Brick Size Mexico

- Suku Cadang Crusher Di Jepang Montenegro

- Phosphate Rock Process Upgrading

- Heavy Calcium Carbonate Mining Crusher Price

- Mining Quartz Arteficial Stone Italy