Mechanism Of Rolling Mill

Rolling (metalworking)

Modern rolling practice can be attributed to the pioneering efforts of Henry Cort of Funtley Iron Mills, near Fareham in Hampshire, 1783, a patent was issued to Henry Cort for his use of grooved rolls for rolling iron bars. With this new design, mills were able to produce 15 times more output per day than with a hammer. Although Cort was not the first to use grooved rolls, he was ...

Vertical Vibration Model for Unsteady Lubriion in Rolls ...

Jan 01, 2012 · According to the vertical vibration phenomena existing in cold rolling mills, the unsteady lubriion mechanism in roll gap and its influence to rolling stability was .

Usha Guides Rolling Systems

Rolling Mill Consumables Entry Roller Guides for Highspeed wire rod block High speed finishing block guides features single point adjustment mechanism with spring preloading to ensure positive and accurate setting, eliminating adjustment creep.

Rolling Mill Equipment

These Hot Saws are used in hot rolling mill to cut desired length and as well as trim Front Rear shears are capable of cutting section size ranging from 70 to 600mm(Beam, Channel, Angle) and as well as Square, Rounds of 40 to 250mm, slabs of Hot saws presently are two types: Pendulum swinging type and horizontal ...

1. MultiHigh Mills (KT/KST Mill) || KOBE STEEL, LTD.

Our 12 or 20high rolling mill is equipped with such adjusting mechanisms as crown, intermediate roll lateral, and tiltingrolling for flatness control measurement. In addition, feed back control is possible with the Automatic Flatness Control System (AFC).

The development of the electromechanical screwdown ...

The mechanisms control scheme and the signals transmission scheme of the rolling mill were composed. The block diagram of the screwdown mechanism motion control system was developed. The simulation results were compared with the data of electromechanical screwdown mechanism of the Magnitogorsk Steel Works hot plate rolling mill "5000".

Rolling process and its influence analysis on hot ...

Nov 09, 2016 · Rolling mill vibration can lead to lowerquality products, equipment failure or damage, personal injury, but because of the complexity of the vibration mechanism, rolling mill vibration is technical problem in the iron and steel industry for many years; people still did not find a .

WSN | Profiles

The WSN type profile rolling machines are always used when profile wires need to be produced to the highest precision. The fundamental mechanical concept with surrounding frame and linear roll positioning with a wedge mechanism gives this machine a very high stiffness. In the development of the WSN profile rolling mill, special emphasis was ...

Reviews in Dynamic Characteristics of Rolling Interface ...

Background: Rolling mill vibration mechanism is very complex, and people haven#039;t found a satisfactory vibration control method. Rolling interface ...

COBBLE RELIEF MECHANISM FOR ROLLING MILL

A cobble relief mechanism for a rolling mill of a continuous metal casting and rolling system wherein the accumulation of rod within the mill housing is relieved by opening a portion of the housing and allowing the rod to play out of the opening. The housing is opened in response to the buildup of the rod within the housing, and when the rod is ...

Rolling Equipment and Systems (Chapter 4)

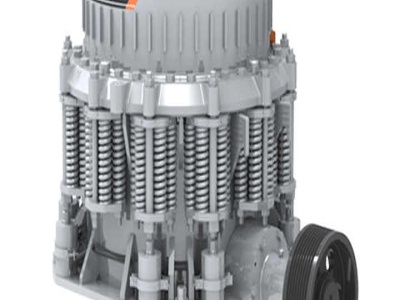

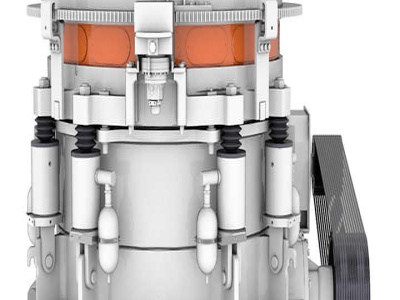

Mill Stand Components and Mechanisms. Most type of rolling mill stands have certain common basic components, mechanisms and systems. These are: (i) Work rolls between which rolling takes place. (ii) Backup rolls to support work rolls, excepting in case of 2Hi, 3Hi mills or cluster mills. (iii) Roll supporting bearing and bearing blocks (chocks).

Design of roller and roll gap adjustment mechanism for ...

Design of roller and roll gap adjustment mechanism for small mill. Pages 124–128. Previous Chapter Next Chapter. ABSTRACT. In order to realize the production of plastic sheet, a small rolling mill is designed according to the large metal rolling mill to roll the plastic products. Meanwhile, the rolling parts with different thickness need to ...

A study of nonlinear coupling dynamic characteristics of ...

The dynamic characteristics of the mill and the drive system are mutually coupled and affected closedloop system. However, most research has considered only th...

What Is A Rolling Mill? | Metal Processing Machinery ...

What Is A Rolling Mill? In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to .

Highest performing Hot Strip Mills | Primetals Technologies

At today's demanding condition, maintaining stable operation of rolling mill is becoming difficult. MSD is a hydraulic cylinder installed to mill housing window and press a roll chock against the opposite side with constant force. MSD eliminates gap between roll chocks and mill housing, keep rolls in proper position and stabilize rolls.

Latest Posts

- الصين خام الكروم طحن الكرة مطحنة الكرة

- آلات البناء والمعدات

- خام الذهب للبيع في غيانا

- المطرقة محطم كاب 3000 طن ساعة

- بيع عجلات آلة الذهب أفضل الأسعار

- ريموند مطحنة دليل التشغيل

- ماليزيا باكستان الذرة الطاحن للبيع

- الأبحاث المتعلقة ب كسارة الفك المحمولة الصغيرة

- الزنك والحديد كرات للبيع في نيجيريا

- الحصى الاتصالات

- أوسبورن الفك محطم صيانة جنوب أفريقيا

- لماذا محطم النطاط تحتاج إلى تنظيف

- حجر سحق آلة صغيرة للرخام

- عصامي الحصى غربال

- Crushing Plant Price In Uruguay Stone Crusher Machine

- Maintenance Of Lakshmi 5 Lit Wet Grinder

- Rare Mr Dudley International Coffee Bean Grinder

- Slag Ball Mill In China

- Portable Limestone Cone Crusher Provider In Malaysia

- Mobile Crushing Plant Manufacturers

- Crusher And Grinding Mill For Quarry Plant In Ethiopia

- Mobile Sand And Gravel Processing

- Process Of Mining Zinc

- Jaw Crusher King Sizes

- Impact Of Vibration On The Foundation Of Jaw Stone Crusher

- Sudan Coal Mining Companies Dumper Trucks

- Milling Machine Made In Venezuela

- Coal And Mining Jakarta

- High Pressure Grinding Rolls Hpgr Koppern

- Specifi Ion Of Jaw Crusher