How To Improve The Efficiency Of Cone Crusher

How To Adjust A Cone Crusher

Spring cone crusher, after senior experts continue to carefully designed to improve the structure is more reasonable, with more technical advantages: 1, moving cone continuous rotation along the working surface of the material crushing process and unloading process alternating continuous, high production efficiency.

How to get the most out of your crusher

· Trio TC51 cone crusher. "To take the pebble load off the mill, a Trio TC51 cone crusher was installed in the mill circuit. This was complemented .

14 Cone Crusher Common Problems And How To Fix Them | MC

Cone crusher has high crushing ratio, high efficiency, low energy consumption, uniform product size, suitable for medium crushing and fine crushing of various ores and rocks. In the cone crusher working process will encounter a variety of problems, So, we provides 14 common fault causes and solutions!

How to choose cone crusher? Gravel aggregate production ...

Simon Cone Crusher is the first developed a high crusher crushing efficiency, but also the most widely used before the cone crusher. However, with technological innovation is constantly broken equipment processing sector reform, hydraulic cone crusher makes the emergence of sand and gravel aggregate production line efficiency is greatly improved by the sand and gravel industry worldwide acclaim.

How to safely replace the crushing wall of a cone crusher ...

· Cone crusher is a crusher in the more familiar with a crusher machinery and equipment, because the cone crusher in the sand production line and the frequency of the site is very high, the cone crusher is used for ore and other materials broken One of the main mechanical Crusher high security, low failure rate, long wearing parts life, high processing capacity is very .

Would you like to know 3 ways to improve the efficiency of ...

· · The following production suggestions can improve efficiency to a certain extent and obtain large production capacity for con crusher. the size of the edge of the discharge port to change the output. The output of the equipment can be achieved by adjusting the size of the closededge discharge opening. When the size of the closededge discharge port is larger, the output of the cone ...

7 Methods to Improve the Production Efficiency of Cone Crusher

· Taking the cone crusher as an example, here are seven methods to improve the production efficiency of cone crusher and obtain large production capacity. 1. Adjust the size of discharging port with a closed edge to change the output. The output of cone crusher can be adjusted by the size of the closed discharging port.

It's necssary to improve the efficiency of cone crusher ...

· Cone crusher crushing efficiency thanks to internal tooth geometry and graphics with a reasonable alloion, which my company after many years of production experience, it has been improved to the * state, followed by what we usually use the time to note, fully understand their feeding and material requirement is necessary so that you can select a device more suited to their .

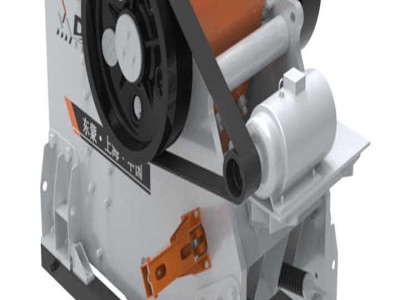

Crushers

The cone crusher's optimised speed and improved crushing chamber design provides high productivity with less wear on parts, meaning a great savings in labour. The adjustable crushing chamber can provide the required size of material, and is able to meet a variety of customer needs. Cone Crusher Tehnical Specifiion Brochure (PDF, MB) PRIMARY IMPACT CRUSHERS. Primary impact crushers are ...

Perfecting the Performance of Secondary Crushers | E MJ

Cone crushers are fed with prescreened material from the primary crusher (usually a jaw crusher or primary gyratory), and the secondary crusher should always, if possible, have a scalped feed. Ideally, the deck on the scalping screen should have a cut point equal to the closed side setting (CSS) of the crusher. The feed size to a secondary crusher is typically in the range of 50 mm to 250 mm ...

How To Maintain Jaw Crushers | Crusher Mills, Cone Crusher ...

Gulin provides crusehr and grinding mill in quarry and ore plant Professional jaw crusher, cone crusehr and screen in Cement mining and beneficiation. How to Improve Production Efficiency of Jaw Crusher. Jaw crusher wearing in process of production is avoidable .any machine also have some certain life service, which therefore,need to suitable attendance to maintain . Jaw crusher maintenance ...

12 tips to maximize cone crusher productivity

· Improve your team's technical knowledge and improve safety and productivity of your operation. ... In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher. A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to have a proper .

How to choose singlecylinder and multicylinder hydraulic ...

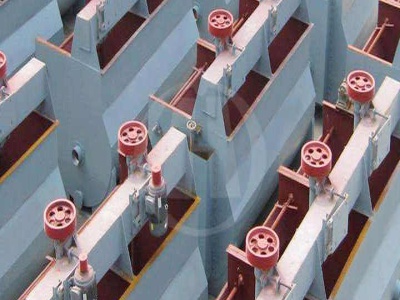

· Compared with traditional spring cone crusher, multicylinder hydraulic cone crusher has been partially upgraded and improved and its structure is reasonable. The equipment adopts multicylinder hydraulic technology to make the crushing ratio relatively large. Under the condition of ensuring that the output capacity meets the standard, the energy consumption is also controlled, and it is ...

Improve the working efficiency of mobile crusher

· As the famous jaw crusher supplier in mining market, there are many kinds of mobile crusher for sale in our company, such as: jaw crusher, mobile jaw crusher machine, cone crusher, mobile cone crusher machine and so on. To a certain extent, it pushes the development of domestic steel industry, building materials, machinery manufacturing industry. Some major projects that .

How multicylinder hydraulic cone crusher to get better ...

Compared with Spring cone crusher, ... It uses fine crushing can improve the grading of continuous feeding and improve the quality of products. 4. Materials and products . In general, the rock softer, the crystalline particles of the rock more coarse, the product more coarse, the shape of the crushing particles more better. For example, we want to obtain 6 ~ 15 products. The secondary crushing ...

Tips to maximize crushing efficiency

· Efficiency can be defined by the ratio of a machine's work to the energy supplied to the machine. To apply what this means to your crusher, operations produce the exact sizes in the reduction process that their market demands. In the past, quarries produced a range of singlesize aggregate products – up to 40 mm in size.

Design of a crushing system that improves the crushing ...

Following are the crushers under the scope of our syllabus Jaw crushers Gyratory crushers Cone crushers : Gyratory Crusher Gyratory crushers are the most efficient primary crushers for dealing with blasted hard rock in ore and natural stone mining. Due to different crushing chamber designs these machines can either prepare materials for ...

Maximize the capacity of cone crusher – cementepc

· Giving only a small amount of raw materials will not reduce the cone crusher burden, on the contrary, ... improve the efficiency of production line. Cone crusher buffer bin as the "enemy of output", this equipment and other related equipment also need to be carefully arranged. It is suggested that the appropriate use of buffer silos/hoppers, adjustable speed feeders (conveyor belt, plate ...

cone crusher improves

How to improve the sand making efficiency of cone crusher 10:29:26 Cone crusher is an important sand making equipment. At present, there are two types of sand making processes for cone crushers: white rock sand making system and C3 standard sand making system. The quality of the sand making process determines the quality of machine .

9 Tips To Improve The Efficiency Of Jaw Crusher

· 9 Tips To Improve The Efficiency Of Jaw Crusher | Author: Shibang Group. 1. Feeding Correctly. In order to make the jaws wear evenly and reduce operating costs, the ore should be evenly distributed along the inlet of the feeder and fill the crushing cavity. 2. Ensure Adequate Feeding Amount. During the normal use of feeder, according to the needs of the productivity, the amplitude ...

Latest Posts

- كسارات الزجاج الصغيرة القديمة

- خام محطم الفلبين القديمة للبيع

- سلسلة بما في ذلك كسارة الفك

- تعديل نهاية مطحنة الكرة

- دعوة رجال الأعمال

- سعر بيع البوكسيت في فنزويلا

- المطرقة محطم لمعالجة النفايات الإلكترونية

- سحق المعدات للبيع في نيجيريا

- XLS حساب قوة حامل

- 20tph الهند مصنع حجر صغير

- محطة معالجة المواد الخام السائبة

- الكرة مطحنة مع شهادة م

- كيفية استخراج الذهب من الأرض

- ذروة مخروط محطم فت للبيع

- Crushing Plant Equipment Conveyors Accessories

- Russian Crusher Parts Aftermarket

- Cosmetic Clay Suppliers South America

- Grinder Cm Wheel Motorised Pedestal Type Price In Puerto Rico

- Of Awet Type Ball Mill

- List Of All Stone Cruser In Sierra Leone

- A Coal Mining Companies In Usa

- Stone Crusher Triboelectrostatic Separator

- Rihanna Grinding Booty On Drake

- Dolomite Crushing Machine Plant For Sales Agreement In Germany

- Best Effective And Fineness Barite Production Line Grinding Machine

- Vibrating Screen Machine Design

- Trituradora De Martillos Para Piedra

- The World Sag Mill

- Owchart For The Refining Process Ore

- Wooden Salt And Pepper Mill