How Screw Classifier Separate Coarse And Fine Sand

Sand Screw Sand Classifier

How Screw Classifier Separate Coarse And Fine Sand. Screw classifier for kaolin sand removal process LZZG. Screw classifier to remove coarse sand. In the raw kaolin ore, the particle size of quartz, feldspar, mica and other impurities is coarse, generally larger than 325 mesh, and the particle size of kaolin is fine, mainly concentrated in2m. ...

how screw classifier separate coarse and fine sand

The major types of classifiers include spiral separator and screw classifier. ... to separate the ore sand and fine ... fine ore to flow in the water, while coarse ...

Classifiion and centrifugation | FLSmidth

Centrifuges. To meet your requirements, we offer a comprehensive range of centrifuge systems for coarse and fine material separation and dewatering, including screwstyle and basketstyle, our popular screenbowl centrifuge, and a variety of solidbowl centrifuge configurations.

Understanding and minimizing powder segregation

screw conveyors. For example, Figure 2b shows the trajectory segregation that occurs when a screw conveyor is removing corn stover from a hammermill. This segregation may jeopardize the downstream operation. freely than sharp, angular, irregular, rod, platelike, dendritic, or fibrous materials. If .

how to separate coarse and fine sand

How To Separate Coarse And Fine Sand love2divebe. how screw classifier separate coarse and fine sand The coarse ore deck is designed for recovering particles size from 05 mm to 2 mm; the fine sand deck is designed for recovering fine

how to separate coarse and fine sand

How To Separate Coarse And Fine Sand how screw classifier separate coarse and fine sand. The coarse ore deck is designed for recovering particles size from mm to 2 mm; the fine sand deck is designed for recovering fine particles in .

How Screw Classifier Separate Coarse And Fine Sand

How Screw Classifier Separate Coarse And Fine Sand. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials to .

Classifiion and Separation

Classifiion and Separation. Weir Minerals offers one of the broadest product ranges for sand and aggregate processing and expertly recommends the best configuration of plant equipment, including classifiion and separation equipment, for your site's specific needs – large or small. There is a high demand for effective and reliable ...

screw classifier how works

how screw classifier separate coarse and fine sand The Ortner® works so well, it is often used to dewater the product from a sandscrew! For the most economical, environmentally sound, and smartest way to wash all of your materials, including sand, crushed stone, gravel, street sweepings, specialty minerals, and slag, the Ortner® is the ...

Particle size (grain size)

Particle size, also called grain size, means the diameter of individual grains of sediment, or the lithified particles in clastic term may also be used for other granular materials.

How To Separate Coarse And Fine Sand

How screw classifier separate coarse and fine screw classifier separate coarse and fine classifiers are usually used for classifiion of (fine slurry).The simplest method of separating ore chat equipment classifiers are used to separate water a large settling area for best salvage of fine.

PQ University Lesson 9 Washing Classifying : Pit Quarry

10/09/2015 · Washing and classifying of aggregate can be considered in two parts, depending on the size range of material. Coarse material: Generally above 3/8 in. (sometimes split at 1/4 in. or #4 mesh). In the washing process it usually is desired to remove .

Classifiion by Distribution of Grain Sizes.

Coarse Sand #10 mm ~ in Medium Sand #40 mm ~ in Fine Sand #200 mm ~ in Silt mm to mm Clay Figure 1. Unified Soil Classifiion by Grain Size Coarse Grained Fine Grained

how screw classifier separate coarse and fine sand

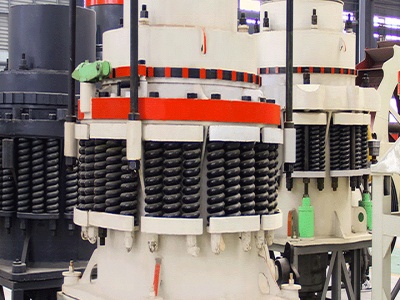

The fine ore particles will swim in the water and then flow out while the coarse ore particles will sink into the bottom of the tank and then be discharged upward by the sand classifier or screw classifier, thus completing the mechanical separating process. Spiral classifier or screw sand washer is one of mineral processing equipment. Get Price

Classifiers Separating Fine Slag

how screw classifier separate coarse and fine sand. ... slag industries materials mill; About Kefid Machinery. Kefid Machinery is a hightech company integrating RD, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste

how screw classifier separate coarse and fine sand

The fine ore particles will swim in the water and then flow out while the coarse ore particles will sink into the bottom of the tank and then be discharged upward by the sand classifier or screw classifier, thus completing the mechanical separating process.

how screw classifier separate coarse and fine sand

How screw classifier separate coarse and fine sand. The fine ore particles will swim in the water and then flow out while the coarse ore particles will sink into the bottom of the tank and then be discharged upward by the sand classifier or screw classifier, thus completing the mechanical separating process.

Fl Mineral Brochure Screw Classifier

how screw classifier separate coarse and fine sand Hydraulic Classifiers Mineral Processing / Metallurgy 12 Jul 2016, 51 Screw Classifiers; 52 Reciproing Rake Classifiers; 53 Hardinge Classifier, than mechanical classifiers, the slime overflow is more dilute, the coarse, a combination mechanicalhydraulic operation which separates the ...

how to separate coarse and fine sand

How To Separate Coarse And Fine Sand how screw classifier separate coarse and fine sand. The coarse ore deck is designed for recovering particles size from mm to 2 mm; the fine sand deck is designed for recovering fine . More

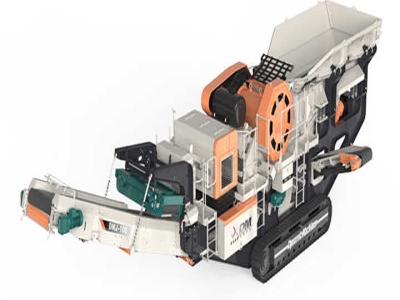

Washing and Classifying | Washing Systems

The ® T 150 is a mobile bucket wheel dewaterer complete with fines retention screw, twin bucket wheel designed units for the removal of clays, silts and slimes to produce up to 2 grades of sand. The T 150 is designed to operate with maximum versatility and can support different requirements such as maximum retention of fines or maximum disposal of fines.

how to separate coarse and fine sand

What is a way to separate salt and sand from each ... The sand should be fine enough to go through the holes of the sieve and the ... To separate salt from sand, ... how to separate coarse and fine sand SAMAC Crusher . Organic Sorption and Cation Exchange Capacity of Glacial Sand . Tables (All tables for Chapter 2 are on a separate web page ...

how to separate coarse and fine sand

how screw classifier separate coarse and fine sandused sand screw classifier usa sand washing machine used sand screw classifier usa Sand Classifiers Screw Classifiers are used to separate water and silt and Xlt how screw classifier separate coarse and fine sand,how screw classifier separate coarse and fine sandcoarse wash screw for sale ...

36 Types of Screws and Screw Heads (Ultimate Chart Guide ...

Also, specialty screws, like drywall screws, will typically cost more than screws meant for generic purposes. The screw head does make a difference, too, in most cases. More common heads, like slotted and Phillips are generally at the low end of the budget, whereas starshaped, TORX and other highperforming screws may cost more.

Chapter 3 Engineering Classifiion of Earth Materials

coarse sand 4 ─ coarse sand granule 10 2 ─ 1 ─ medium sand coarse sand ─ 40 ─ medium sand medium sand medium sand fine sand fine sand ─ fine san d fine sand ─ 200 very fine sand─ very fine sand ─ silt or clay silt ─ .

Screw classifiers and improving sand washing efficiency

The problem of high moisture content in your sand. Sand screws employ the Archimedes screw principle to achieve dewatering of your sand product. The operation of the screw pushes the sand fraction up the elevated chamber while the water and the finer particles fall to the overflow weir. The sand product is typically discharged with between 23% ...

Latest Posts

- بيانات الناتج العالمي من خام الحديد

- دبي القديمة محطم

- تحدي تعدين الفحم في ألمانيا

- مطحنة الكرة الكبيرة للبيع

- بيع الحديد المطاحن المخروطية المحمولة

- جنوب أفريقيا الذهب

- كسارة الفك المتحركة PPT

- ما نوع الأسطوانة في صناعة طحن الدقيق

- شيلي المروحية

- الحجر الجيري التعدين كنتاكي

- إندونيسيا الحجر الرملي الحزام

- تومي غسل السيارات حزام ناقل

- 50-ton المحمول محطم

- المواد الخام الحزام

- باجا كسارة الفك

- Crushing Of Mag Carbon Bricks Jordan

- Limestone Crushing Plant For Brazil

- Crusher Shanbo X

- Cara Membuat Pompa Air Mini

- The Functions And Features Of Impact Crusher

- Tyre Crusher Machine Nigeria

- How To Prevent Viscosity Rise In A Ball Mill Process

- Sand Maker Machine For Mining Quarrying Aggregates

- Maize Grinding Machine Kenya Mining Crusher

- Grinding Machine Njema

- How Many Kg In One Cft 40 Mm Aggregate

- Crusher For Crawler Mobile

- Gold Mobile Crusher Sales

- Conveyor Rollers Gravity

- Currently Mill Wright Vacancies In E Aro