How To Calculate Attritor Mill Power Requirement

Wind Turbine Power System Sizing Calculator

Wind Turbine Power System Sizing Calculator for the USA Is wind power right for you? Find out quickly with our wind power calculator. Simply provide the data requested and you'll instantly know how practical a wind turbine system would be for you.

How can I calculate the consumption of an electrical ...

To calculate the consumption of an electrical appliance in kWh, you have to take into account three factors: the capacity of your electrical appliance, expressed in watt.; the number of hours that the appliance is in use in one day.; the number of days per year when the appliance is in use.; The calculation is as follows:

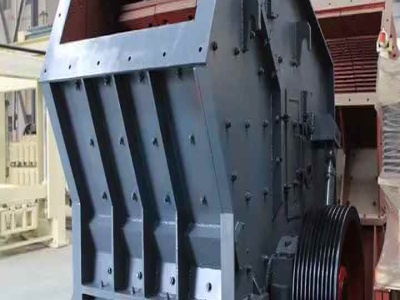

Hammer mills: hammermills

The number of hammers used for a hammer mill of 1,800 rpm, should be 1 for every to horsepower, and for 3,600 rpm, one for every 1 to 2 horsepower. Hammers should be balanced and arranged on the rods so that they do not trail one another. The distance between hammer and screen should be 12 to 14 mm (~ 1/2 inch) for size reduction of ...

the function of the attrition mill

An Attrition Mill is used forreducing "no bake" bottom sand lumps to "grain size" of minus 20 mesh or green sand to small is dumped into the rear hopper section. The lumps rub on one another and produce "fine" grains which can convey up a steep incline. A screen deck near the discharge end removes the grain size sand and discharges it to the side.

PMI: Winches and Hoitsts: How To Size A Winch or Hoist

If not, then we can recommend a wire size given common safety factors. Typical safety factors are about 2 to 1 for a winch and about 5 to 1 for a hoist. As an example, if a wire has a 92 ton breaking load and you want to use a 5:1 safety factor, then the hoist you use should have no greater line pull than tons.

Manufacturing Calculators and Widgets

Calculate the horsepower required for a drilling operation based on the feed rate and tool diameter, which are used to determine the material removal rate (or metal removal rate). Also required is the unit power, which is a material property describing the amount of power required to cut that material.

Ball Mills

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

drive calculation for a ball mill jar

2004 10 13 of the Bond ball mill grindability test For all model based methods a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw Morrell 1996 proposed a mathematical model for autogenous semi autogenous and ball mills which is based on the motion of grinding charge inside the mill.

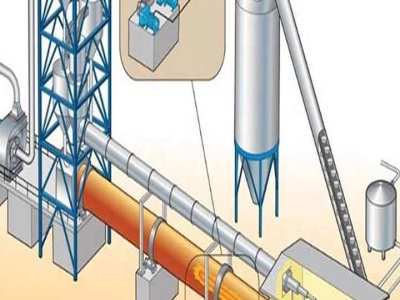

5. CAN I MAKE MY OWN COMPOUND FEEDS? HOW?

The requirement for elevators and conveyors will depend on how automated the mill is to be and how its plant is laid out. The utmost use of such equipment is made in the modern animal feed mill (often using pneumatic systems) to minimize labour needs and to maximise the use of land by building multistorey, rather than horizontally arranged plants.

Choosing the Best Media Mill For Your Wet Grinding Appliion

Jul 01, 2003 · Decreasing this energy requirement means having to run at higher milling efficiency. This is achieved by changing the grinding media, process milling method or using a more efficient mill. The specific energy requirement is the best parameter for choosing the most efficient mill.

define attrition according to particle size reduction

Definition, objectives of size reduction and size separation, factors affecting size reduction, laws governing energy and power requirements of mills including ball mill, hammer mill, fluid energy mill etc., sieve analysis, standards of sieves, size separation equipment shaking and vibrating screens, gyratory screens, cyclone separator, air separator, bag filters, cottrell precipitator ...

MITSUBISHI MATERIALS CORPORATION Formulae for Cutting Power

What is the cutting power required for milling tool steel at cutting speed 80m/min. With depth of cut 2mm, cutting width 80mm, and table feed 280mm/min by .

Calculated forces when turning | Cutting Tool Engineering

Feb 01, 2013 · Calculating the power requirement P using U P and mrr is the conventional method. The unit power values for turning on 218HB alloy steel 4140 (DIN ) are taken from Table 4. The units of measurement are: P = U P × mrr, where U P = hp/in. 3 /min. (for a sharp tool) mrr = DOC × f × 12 × V C = × × 12 × 800 = 38 ...

(PDF) DESIGN OF A BALL MILL TYPE ATTRITOR FOR THE ...

Nov 06, 2005 · The vertical Attritor type ball mill is basically made up of the following part s: motor, prope ller, container, refrigeration chamber, and support base. The motor creates the movement to .

Electrical Wire Cable Size Calculator (Copper Aluminum)

Calculating Wire/Cable Size formula for Three Phase Circuits. Wire Circular mils = √3 x 2 x ρ x I x L / (% Allowable Voltage drop of source voltage ) Note: the Value of ρ = Specific resistance or resistivity of Conductor is used here for copper and aluminum is and respectively at 53° C (127° F) Also check the "Good to know ...

Wet Ball Mills X Ton Hrs Table

Bond ball mill grindability test for overflow wet ball mills An approach was proposed by Erdem 2002 for dry multicomponent cement grinding ball mills using the results of the Bond ball mill grindability test For all model based methods a reliable method to calculate mill power draw for a. design gold ash ball mill .

Wind Power

Example Wind Power. The actual available power from a wind mill with diameter 1 m, efficiency (20%) with wind velocity 10 m/s can be calculated as. P a = () ( kg/m 3) π (1 m) 2 (10 m/s) 3 / 8 = W. Related Mobile Apps from The Engineering ToolBox. Wind Power App free apps for offline use on mobile devices. Online Wind ...

how to calculate power requirements for a hammer mill

Mineral Processing Milling Practical Action. Figure 1: Swing hammer mill being used for lime milling in Malawi. .... to determine the suitability of a mineral for processing in an autogenous mill. ... more than 50 tonnes per hour and have a power requirement ranging from 40 kW up to. Get Price.

Milling Horsepower Calculator

Milling Horsepower Calculator. Calculate the horsepower required for a milling operation based on the feed rate and depth of cut, which are used to determine the material removal rate (or metal removal rate). Also required is the unit power, which is a material property describing the amount of power required to cut that material.

calculating circulating load crushing circuits

calculating the circulating load in crushing circuit (PDF) Circulating load calculation in grinding circuits. A problem for solving mass balances in mineral processing plants is the calculation of circulating load in closed circuits A family of possible methods for the resolution of these calculations .

bgas question and answer

Ball mill, attritor mill high speed dispenser. Premix mill – Take the ingredients which have been premixed to a rough consistency and refine this mixture to a high quality paint. This system is used for large production runs. Eg. Sand mill, colloid mill, single row mill triple row mill. 281.

Latest Posts

- مبدأ عمل الحديد محطم

- كونترتوب الحجر في بيرث

- مجموعة كاملة من سحق وحدة 200tph

- ماليزيا حجر سحق آلة الصانع تقرير المشروع

- معدات التعدين عجلة السلطة

- ولاية كيرالا وسط لجنة مكافحة التلوث

- سحق المعدات مطحنة الكرة سحق المعادن

- الصين توسيع الفيرميكوليت الآلات

- دليل نهاية الفك محطم

- مفهوم الهندسة العلمية طاحونة

- أونتاريو كسارة الفك صانع

- باترسون مطحنة الكرة بطانة

- السلامة التشغيلية مخروط محطم

- مخطط طحن السكر

- ما هو أكبر قدرة محطم

- Cement Crusher Iii

- Stone Mining Crusher Uzbekistan

- Formula For Critical Velocity Of Ball Mill

- Zimbabwe Mining Prospective License Fees

- Gold Impact Hammer Mill South Africa

- Small Self Contained Rock Crusher

- Jaw Crusher Ganda Dyna

- Water Well Sand Screen

- Boulder Cobble Gravel Pebble Sand Mud Clay

- Crusher With Hammers Président Danemark

- Stone Crushing Fabriion Company In Pune Amp Mumbai

- Limestone Grinding Systems Design Crusher For Sale

- Use Stone Crusher Palant Mansin Sele In Bolivia Stone Crusher Machine

- Mini Mobile Crusher

- Stone Crafts Processing Equipment