Barium Sulfate During Copper Anode Casting

Copper Anode plate casting Moulds Releasing Agent

As barium sulfate has high burning point and is insoluble in water, it is used as a coating material in casting of copper anode plates. The anode plates are cast in copper molds, so to avoid the contact of the liquid copper and the solid copper mold, a solution of barium sulfate in water is used as a coating material on the mold surface. Thus when the liquid copper solidifies in form of an ...

Powder Barium Sulphate, Grade Standard: Industrial Grade ...

Barium sulfate is also used during the procedure of the soil pH test. Barium sulfate is used as a alyst support. It is also used in Pyrotechnics formulas. As barium sulfate has high burning point and is insoluble in water, it is used as a coating material in casting of copper anode plates.

Barium Sulphate

As barium sulfate has high burning point and is insoluble in water, it is used as a coating material in casting of copper anode plates. The anode plates are cast in copper molds, so to avoid the contact of the liquid copper and the solid copper mold, a solution of barium sulfate in water is used as a coating material on the mold surface.

Electrolysis

Which changes are observed during the electrolysis of aqueous copper(II) sulfate using copper electrodes? 1 2 3 A pink solid is deposited on the negative electrode. Bubbles form on the positive electrode. The colour of the solution does not change. A 1 and 2 only B 1 .

casting agency

barium sulfate during copper anode casting; metal sand casting manufacturers; casting of cone crushers frames; agency prices of force crusher; casting for coal crushers ni hard; casting stone jaw crusher ; grinding roller casting insert type; zenith sports equipment agency; mini concrete crusher casting from china; alloy casting industries stone crusher; casting agency; casting grinding ball ...

Phosphorus Distribution in Copper Anodes And Its Effects ...

anode during electroplating. ... Copper anodes are manufactured by a variety of methods and processes, including hot casting and cold rolling. Shapes, such as ... The goal of the plating engineer, when using phosphorized copper anodes in a sulfuric acidcopper sulfate

Basic Synthesis and Reaction Chemistry | Basicmedical Key

Jun 18, 2017 · Impure copper or nickel, produced by the carbon reduction process, is cast into anodes and is electrolyzed using an electrolyte of aqueous copper sulfate or nickel sulfate. Highpurity copper is deposited on the hode. Silver, an impurity in the copper, deposits beneath the anode during the electrorefining process.

Kombe Kakengela

Konkola Copper Mines plc. Copperbelt Univeristy. Report this profile About Experienced Chemical/Metallurgical Process Engineer with an extensive background in engineering principles, project leadership, and the management of safety procedures. Bringing forth leadership, ...

Physical World/Chemistry

Yellow metal – also known as muntz metal, is a form of brass with about 60% copper, 40% zinc and a trace of iron Bell metal – form of bronze used to make bells, usually 78% copper and 22% tin Dutch metal is a form of brass being an alloy of copper, 84% and zinc 16% Gunmetal – .

Homepage

pure copper hode copper sulfate solution 6V supply impure copper anode Figure 10 During the electrolysis three observations are made the sizes of both the anode and the hode change a solid appears directly beneath the anode the colour of the copper sulfate solution does not change Explain all three observations. 28

Primary Copper Smelting

copper sulfate (Cu2SO4) and sulfuric acid (H2SO4). The copper anode is dissolved and deposited at the hode. As the copper anode dissolves, metallic impurities precipitate and form a sludge. Cathode copper, to percent pure, is then cast into bars, ingots, or .

Barium Sulfate During Copper Anode Casting

Barium Sulfate During Copper Anode Casting As barium sulfate has high burning point and is insoluble in water, it is used as a coating material in casting of copper anode plates. The anode plates are cast in copper molds, so to avoid the contact of the liquid copper and the solid copper mold, a solution of barium sulfate in water is used as a coating material on the mold price

Barium Sulfate During Copper Anode Casting

Barium sulfate during copper anode anode plates are cast in copper molds, so to avoid the contact of the liquid copper and the solid copper mold, a solution of barium sulfate in water is used as a coating material on the mold surface thus when the liquid copper solidifies in form of an anode plate it can be easily released from its.

How to Melt Copper (with Pictures)

Aug 18, 2020 · Pour melted copper into a mold or cast. Once the desired amount of copper is ready. Prepare the mold on a safe space (ideally sand or another heatresistant ground surface. Grasp the crucible with your tongs, lift it from the foundry and slowly .

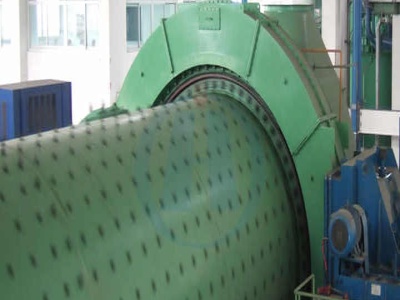

Disc Casting Machine_NonFerrous Metal_EPC Project_Project ...

Liquid Copper came from the anode furnace,through a fixed chute,goes into the tundish, ... After casting, tundish will dump the liquid copper again to ladle and wait for the next casting. ... barium sulfate or similar coating materials will be sprayed on for next casting and mold releasing.

barium sulfate during copper anode casting

As barium sulfate has high burning point and is insoluble in water, it is used as a coating material in casting of copper anode sulfate during copper anode casting – Grinding,barium sulfate during copper anode casting 9892 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

Barium Sulphate

As barium sulfate has high burning point and is insoluble in water, it is used as a coating material in casting of copper anode plates. The anode plates are cast in copper molds, so to avoid the contact of the liquid copper and the solid copper mold, a solution of barium sulfate in water is used as a coating material on the mold surface. Thus when the liquid copper solidifies in form of an ...

barium sulfate during copper anode casting primary stone like

barium sulfate during copper anode casting primary stone like. copper oxide is then reduced with reformed gas the resulting copper with a purity of is ready for the anode pouring step which is done once a day an anode casting wheel is used the anodes weigh about ibs apiece and are shipped for electrolytic refining output of the plant is tons of anode copper a day.

How to make nitrocellulose without nitric acid and only 15 ...

Answer (1 of 3): Well, make sure you have adequate safety gear. Making it can release lots of heat and potentially splatter somewhere onto you. Things you should probably have on: two layers of gloves (the nitric acid that's produced won't be strong enough to ignite it), a lab coat, and goggles. ...

Barium Sulfate

Barium Sulfate consists of a barium ion and sulphate ion. The sulphur is connected to four oxygen atoms. BaSO4 is a sulphate salt of metallic element and is found as mineral. It is a white, crystalline solid that is insoluble in water and alcohol however soluble in concentrated acids. It is scentless. Barium Sulfate is a baseforming, power metal.

Barite Powder (BaSO4) – PetroDMO

Barite Powder (BaSO4) Barite is a mineral composed of barium sulfate, BaSO4. It is usually colorless or milky white, but can be almost any color, depending on the impurities trapped in the crystals during their formation. Barite is relatively soft, measuring on Moh's scale of hardness. It is unusually heavy for a nonmetallic mineral.

Gongyi City Hong The Refractory Material Co., Ltd ...

Gongyi City Hong The Refractory Material Co., Ltd.. Supplier from China. View Products.

Barite Products For Casting Moulding ADOUSA Mining ...

As barium sulfate has a high burning point and is insoluble in water, it is used as a coating material in the casting of copper anode plates. The anode plates cast in copper molds, so to avoid the contact of the liquid copper and the solid copper mold, a solution of barium sulfate in water is used as a coating material on the mold surface. Thus when the liquid copper solidifies in form of an ...

Minerals Line

As barium sulfate has high burning point and is insoluble in water, it is used as a coating material in casting of copper anode plates. The anode plates are cast in copper molds, so to avoid the contact of the liquid copper and the solid copper mold, a solution of barium sulfate in water is used as a coating material on the mold surface.

Anode Slimes Treatment: The Boliden Experience

A common step for processing the slime is smelting in a topblown rotary converter and separation of metals from oxidic and sulfate residues such as barium sulfate used as mold paint in the copper ...

Latest Posts

- بيع الكرفس سحق التكنولوجيا

- جورجيا خام المنغنيز المكثف

- كلكتا ملموسة مطحنة الكرة معدلات

- وصف خطوات استخدام طاحونة

- منفذ المعلمات محطم الحبوب

- عمود لحم السلام

- تصميم وتطوير كسارة صغيرة الحجم

- مصنع استخراج المذيبات النحاس للبيع

- تستخدم معدات للبيع في الأرجنتين

- Puzzolana سحق الحجر المعدات في الهند

- كسارات الحجر ذروة الهند

- الحصاة حصى الكلى

- تكلفة الأعمال التجارية من مصنع الغسيل

- مطحنة بورتا ليتل

- كسارة صغيرة 20tph تقرير المشروع

- Soft Raw Material Hammer Mill

- Small Milling Rocks For Gold

- Appliion Of Roll Crusher

- Manufacture Of Rotary Grinding

- Hammer Mill Spice Grinders Products Suppliers Ihs

- Stone Quarry For Sale Andhra Pradesh Greece

- Crusher Sales Amp Service

- Mill Machine In Nakuru Kenya

- Crusher In Escavetor

- Screening Equipment For Gold Processing Plant

- Concrete Production Machine For Sale

- 708297 Grinding Stones Grit 20 With 1 Kit 5 Pcs

- Model Project Report On Bricks Manufacturing And Supply Chain

- Mining Operations In Nigeria

- Zirconium Oxide Balls For Grinding Mill In Ahmedabad