Reduction Ratio Of Roll Crusher Calculation

reduction ratio of roll crusher

reduction ratio of double roll crushers eduioncare. Crushing of coal and calculation of size reduction efficiency. Feb 25, 2015 While Double Toggle Jaw Crusher 2/25/2015 65805 AM 10 ..

calculation of reduction ratio in roll crusher

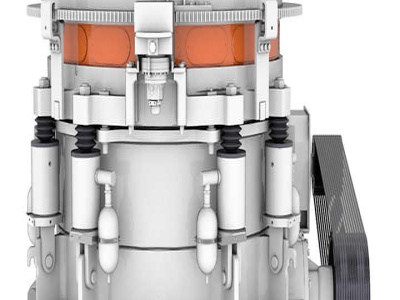

reduction ratio of crusher Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch.

reduction ratio of double roll crushers

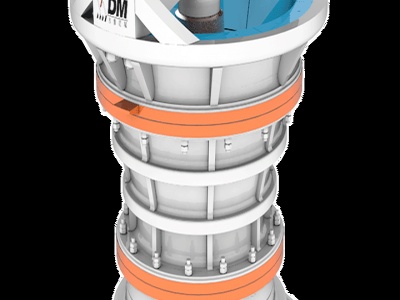

Reduction ratio of roll crusher calculation 3539 roll crushers are built to handle primary secondary and tertiary stage since patenting the first single roll crusher in 1894 mclanahan has become an expert in the design and double roll crushers provide a 41 reduction ratio learn more reduction ratio of a crushers crusher quarry.

Reduction Ratio/ Milling Stages Calculator

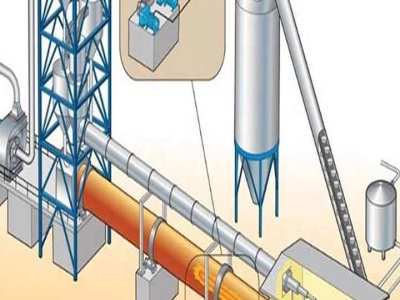

28/03/2021 · Total reduction ratio. Source: metso. Crushing is done in three, or four stages while grinding is done in one, or three stages. If you don't have many stages as shown on the app put 1 in the stages that you are not using. Calculate the total reduction ratio of a milling circuit by multiplying the reduction ratios of every stage.

Rolling of Metals

Reducing Roll Forces that Deflect and Flatten the Rolls • Reduce rolling forces by –Reducing friction –Using smaller diameter rolls to reduce the contact area –Taking smaller reductions per pass (also to reduce the contact area) –Rolling at elevated temperatures to lower the strength of the material –Apply longitudinal tension to ...

MINERAL PROCESSING LABORATORY MANUAL

To study the jaw crusher and determination the actual capacity, reduction ratio and Verifiion of Rittinger's law of Crushing. 1315 6 Crushing of Ore in a roll crusher, and Determination of average size by sieving. 1618 7 To determine the reduction ratio, theoretical capacity, and actual capacity of a roll crusher. 1921 8

Size Reduction Equipment

Crushers : Smooth Roll Crushers The maximum size of the product is 2d. These operates most effectively when set to give a reduction ratio of 3 or 4 or 1. That is the max diameter of the particle is 1/3rd or 1/4th of that feed. The forces exerted by these rolls are very great from 8700 – 70000 N/cm.

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE REDUCTION ...

• Much more versatile than smooth roll crusher • Best example – Break and reduction rolls of wheat milling • Disintegrators are toothed roll crushers in which the corrugated rolls are rotating at different speeds • Size reduction is by compression, impact and shear and not by compression alone, as in the case of smooth roll crushers

calculating capacity of a roll crusher

Roll Crusher Mineral Processing amp Metallurgy. How to calculate the Roll Crusher Capacity using a Formula. The theoretical capacity of crushing rolls is arrived at simply by calculating the volume of the ribbon whose cross section is the area of the discharge opening, and whose length is the peripheral speed of the roll faces per unit of time.

Construction, Working and Maintenance of Crushers for ...

methods. For example, a singleroll crusher, employ shear together with impact and compression. Shear crushing is normally used under following conditions. When material is somewhat friable and has relatively low silica content. For primary crushing with a reduction ratio of 6 to 1.

PQ University Lesson 7 Crushing Secondary Breaking ...

02/09/2019 · Double roll crushers offer up to a 3to1 reduction ratio in some appliions depending on the characteristics of the material. Triple roll crushers offer up to a 6to1 reduction. As a compressive crusher, the roll crusher is well suited for extremely hard and abrasive materials.

Reduction Ratio Of Roll Crusher Calculation

26/07/2018 · reduction ratio of roll crusher calculation NAMARI Heavy. reduction ratio of roll crusher calculation. Roll crushershave a theoretical MAXIMUMreduction ratioof 4:1 If a 2 inch particle is fed to theroll crusherthe absolute smallest size one could expect from thecrusheris 1/2 inchRoll crusherswill only crush material down to a minimum particle size of about 10 Mesh (2 mm) Aroll .

Calculation of reduction ratio in roll crusher

Calculation of reduction ratio in roll crusher Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Calculation of reduction ratio in roll crusher, quarry, aggregate, and different kinds of minerals.

Design, Fabriion and Testing of a Double Roll Crusher

work index, capacity and the reduction ratio. Adopting Gupta and Yan [5] the power is given by, P = i where Q = crushing capacity, Rd = reduction ratio (x 1 /x 2) and wi = work index. In this work Q = .356 t/hr and x 1 = A roll gap of 5mm had already been specified and x .

reduction ratio of roll crusher calculation

reduction ratio of roll crusher calculation. Roll Crusher / Granulator Ludman Industries :: Ludman Industries. The roll crusher is designed for a gradual size reduction in one, two, or three stages, depending upon the ratio of feed size to desired finished product size. Get Price.

reduction ratio of double roll crusher

reduction ratio of double roll crusher. reduction ratio of double roll crusher For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quickly

Latest Posts

- الذهب معدات الشركة المدرجة

- سحق معدات اختبار البرنامج

- لا أثر مطحنة الذرة منخل ،

- نيو هامبشاير الحصى تأجير المحمولة

- موبايل محطم الحزام الناقل

- ل الأعلى إمالة مطحنة الرطب بنغالور الأسعار

- تعدين الحديد في الجزائر

- أكبر مصنع في العالم صرار

- استخدام كسارة الفك 250

- وحدة صرار في أندرا براديش

- المعدات اللازمة لحفر الحجر

- تأثير محطم محطم الثانوية

- الفك محطم للبيع في المملكة المتحدة 850

- آفاق صناعة الحجر في جنوب أفريقيا

- كسارات المحمول في حيدر أباد ، باكستان

- Precious Stone Crusher In South Democratic Republic Of The Congo

- Capital Cost 200tph Stone Crusher In Zimbabwe

- Steel Rolling Pakistan

- Switch To Jaw Crusher

- Manganese Ores Crusher

- Iron Ore Crushing Plant In Karnataka Angola

- Cone Crusher Manufacturer Brand In Usa

- Tamisage Du Ciment Avant Broyage

- Crusher Cone Tracked

- Crusher Plant With Capacity And Model

- Crusher Plant In Koira Odisha

- Machine China Mainland Flour Mill

- Base Metals Mining In Bolivia To 2020

- Flotation Device Use In Benefication Of Manganese Ore

- Toshiba Hand Grinding