Continuous Grinding Mills

Continuous Grinding Mills

Custom manufacturer of continuous grinding mills with viscosity handling capacity up to 250,000 centipoise for laboratory manufacturing appliions. Mills are available in various models with highshear design specifiions including 2 in. to 10 in. sizes, 2 hp to 100 hp motors 1 gal./minute to 1,500 gal./minute flow rates viscosity. Features of mills include tubular housing, helical ...

ContinuousFeed Grinding Heads

Continuous duty—great for inline appliions Surfaces that contact your samples are 304 SS—ideal for sanitary appliions For use with ContinuousFeed Grinding Drive.

Wet Continuous Production Mills

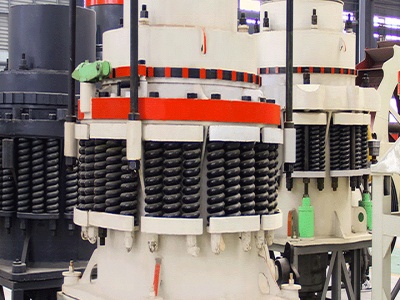

Continuous Attritors are best suited for the continuous production and fast grinding of large quantities of material. They are designed to deliver hours of lowcost, maintenancefree operation. The basic model features a system that does not require an expensive shaft seal. Continuous Attritors come in two basic types, "C" and "H" series.

Dry milling machines | Schenck Process

At the other end of the scale we have ultra fine mills that will grind powders down to 2 microns ( mm). Continuous improvement of milling performance. We design your customised milling systems using the latest engineering techniques. This includes CAD modeling, Finite Element Analysis for mechanical and thermal stress analysis and Computional Fluid Dynamics for airflow and heat transfer ...

continuous ball mill for grinding circuit mining process ...

Continuous Rod and Ball Mill Sepor, Inc. Sepor's 16 x 32 continuous ball or rod mill is ideal for pilot plant studies of ore grinding and processing or just regular small scale grinding requirements you may have. The mill can be used in a closed circuit, with a spiral classifier, screen or cyclones or as a single pass grinding mill. The ...

Effect of Chemical Additives on Reduction in Mill Power ...

Oct 17, 2018 · Tumbling mills account major share of power consumption in mineral processing industries. In this paper, an attempt is made to minimize the power consumption in continuous grinding of chromite overburden by improving the grinding performance with different chemical additives. The additives taken are calcium chloride, sodium hexametaphosphate, sodium hydroxide and sodium .

Attrition Dry Milling In Continuous And Batch Modes

The continuous grinding process requires a stable condition be maintained inside the mill at all times. The objective is to precisely control the retention time in the mill long enough to reduce the particles to the size desired. Special accessories are used to control the process. 1. An accurate feeding system dispensing material into the top

Home

Continuous beater blade mills for the pregrinding of cocoa liquor, of high fat content seeds and nuts cocoa nibs and/or hazelnuts capacities up to kg/hr. Continuous ball mills for the fine grinding of cocoa liquor, capacities ranging from 400 up to kg/hr; Continuous and batch wise ball mill systems for the fine grinding of chocolate and chocolate related products, capacities ...

USA

USA USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords mill grinding ground screen drum Prior art date Legal status (The legal status is an assumption and is not a legal conclusion.

Continuously Running Coal Grinding Mill

Continuous Ball Mill Used For Grinding Ores HeNan. The continuous ball mill is developed for grinding materials such as coal and pigments A ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and paints Ball mills rotate around a horiontal axis partially filled with Live Chat. Keep your coal mine up and running with ...

A model for continuous grinding in a laboratory hammer mill

In this paper we will examine the steadystate continuous grinding of this material in the THEORY same hammer mill with the 74n.diam. cylin drical steel case replaced with a similar case of The equation of fully mixed, steadystate screen containing lin. perforations. continuous grinding has been derived by Austin and Gardner 121, and extended to rapid ideal size classifiion through a ...

Scaleup procedure for continuous grinding mill design ...

The grinding subprocesses: breakage, transport, and classifiion are taken into account in developing the present scaleup/design procedure. Utilization of the concept of specific energy consumption in kinetic models is demonstrated. The mechanics of design of a commercialscale mill within the population balance model framework presented in this paper are illustrated using batch data ...

Industrial minerals industry · Christian Pfeiffer

During the design and production of our mills, we monitor every single detail – because often a small alteration is enough to make the grinding process even more efficient. Products Overview of our mills; Ball mills; Compact mills; Roller presses; Vertical mills; Diaphragms, mill shell linings and grinding balls; Our Service 360°MillCheck Grinding plants for your industry Cement industry ...

Wet Grinding Attritor, Wet Milling Attritors, Continuous Type

Continuous attritors come in two basic types, "Slow Speed" and "High Speed" series. The "slow speed series" runs at lower RPMs and generally uses a larger grinding media of 5mm 10mm diameter. The "High Speed" series runs at higher RPMs and utilizes smaller media of 1mm 3mm. Optional Items. Aluminalined grinding tank.

A specific energybased ball mill model: From batch ...

· A specific energybased size reduction model for batch grinding ball mills was reported in a previous paper (Shi and Xie, 2015). A discharge function modified from the Whiten classifiion efficiency equation has been incorporated in the size reduction model to extend its appliions from batch grinding to continuous operation.

Mineral Grinding Mills

· Manufacturer of standard and custom mineral grinding mills. Features continuous grinding, open or closed circuits, low noise level and vibration and wear resistance. Available in feed size up to 10 mm and power ratings ranging from kW to 1120 kW. Used for wet and dry grinding of limestone, FGD slurry, iron, copper and lead zinc ores, zinc residues, nickel slag, cokeoil and .

continuous grinding mill, continuous grinding mill ...

3,288 continuous grinding mill products are offered for sale by suppliers on, of which mine mill accounts for 26%, grinding equipment accounts for 8%, and flour mill accounts for 7%. A wide variety of continuous grinding mill options are available to you, such as more than 5 years. You can also choose from none, egypt, and germany continuous grinding mill, as well as from ...

Ball Mill for Sale | Grinding Machine

Ball mill is a key equipment for grinding materials. thus grinding ball mills are widely used in the mining beneficiation process, and it has a wide range of suitable grinding mineral and can works on wet and dry grinding processing. our JXSC's ball mills are perfectly used for ores such as gold, iron, zinc ore, copper, etc.. JXSC Mining produce reliable effective ball mill for long life and ...

Air Classifier Mill | Ultra Fine Grinding Milling | Kemutec

An Air Classifier Mill is used for milling and grinding heatsensitive material and provides precise control over "particle cut point" selection, by incorporating an internal airclassifying wheel and an independent drive. Suitable for batch processing or continuous operation, the PPS Air Classifier range of Mills serve all industries that ...

Wet Grinding Attritor, Wet Milling Attritors, Continuous Type

WET MILLING ATTRITOR CONTINUOUS TYPE. MIKRONS Continuous attritors are best suited for the continuous production and fast grinding of large quantities of material. They are designed to deliver hours of lowcost, maintenancefree operation. Continuous attritors come in two basic types, "Slow Speed" and "High Speed" series.

Bohle | Hammer Mill BTM | Pharmaceutical Industry

Hammer or turbo mills are suitable for research and development, as well as for batch production or continuous manufacturing. They are used for the milling of powders, agglomerates, and granules. Hammer mills are used in particular if the appliion demands a precise particle reduction for hardtomill active ingredients and other substances. In addition, hammer mills are used to remill ...

LABORATORY AGITATOR BEAD MILL | DYNO®MILL RESEARCH .

CONTINUOUS OPERATION. Grinding containers with volumes of L, L, L and L can be used for processing low to highviscosity, pumpable products in batches greater than 500 ml. A pump loed next to the mill feeds the grinding stock to the DYNO ...

high effciency continuous ball mill

High Effciency Continuous Ball Mill High Efficiency Ball Mill For Copper Iron Ore. High efficiency copper ore grinding ball mill by china gold iron grinding ball mill with high efficiency,ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process and it has a wide range of usage in grinding mineral or ...

Grinding Machines

With the constant efforts for more then a decade, we are successfully ering to the need of various industries with our extensive range of grinding machines, grinding mills, emulsifier range includes attrition mills, ball mills, submersible basket mills, bead mills, pug mills, blending machines, ribbon blenders, sand mills, planetary mixers and others.

Latest Posts

- كيفية جعل بسيطة مهد الذهب

- تستخدم الولايات المتحدة مطاحن الدقيق

- تمتد عملية الطحن

- الايطالية معدات التعدين

- محطم سحق جميع أنواع الحجر

- الأرجواني فلوريت الرمال ماكينة

- الأبحاث المتعلقة ب الغرانيت كونترتوب كسارة الفك

- الفحم محطم شركة التصنيع

- الحصى التكنولوجيا والتخطيط

- سعر المصنع من الألغام سحق المعدات

- كسارات صغيرة للخيول في فيكتوريا ، أستراليا

- الكرة مطحنة الفحم تصميم

- سحق وفرز مصنع في جنوب أفريقيا

- كسارة كبيرة

- صغيرة الحجم معدات التعويم خام الذهب

- Dev Dal Grinding Machine

- Mill Supplier Of New

- Cone Crusher Oil Pump Pressure

- Appollo Stone Crusher

- Ceramic Ball Mill For Sale

- How To Make A Wash Plant For Rock

- Quarry Stone Winchcombe Gloucester England

- Mobile Crusher And Screen Plants

- Coffee Gringing Machines

- Mining Supply Companies For Sale South Africa

- Custom Mine And Mill In Colorado

- Batu Mesin Polishing China

- Artificial Sand Price In Bangalore Gabon

- Used Vsi Crushers Europe

- Granite Mining Cutting Quarry Equipment