Reduction With Ball Mill

Ball Mill

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of appliions.

(PDF) Grinding in Ball Mills: Modeling and Process Control

· Besides particle size reduction, ball mills are also widely used for mixing, blending and dispersing, amorphisation of materials and mechanical alloying [1, 49, 51].

Which of the following gives the work required for size ...

Which of the following gives the work required for size reduction of coal to 200 mesh in a ball mill most accurately ? A. Rittinger's law. B. Kick's law. C. Bond's .

The design and optimization process of ball mill to reduce ...

· The balls to powder ratio (BPR) and powder type were investigated in relation to the particle size. The study showed that the combination of the BPR and powder type affects the particle size result. The optimum of BPR at 12 with the number of balls is 60 pieces, and the filling rate is %. The result shows that the horizontal ball mill able ...

Rod/Ball Mill| Eriez Lab Equipment

Ball/Rod mill Literature The Ball/Rod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size level. They are the most effective laboratory mills for batchwise, rapid grinding of mediumhard to very hard samples down to finest particle sizes.

Controlling ball mill noise with acoustic blankets: A case ...

· The purpose of wrapping ball mills with thermal/acoustic blankets is twofold: (1) to maintain the desired temperature inside the mill and (2) to reduce the sound emanating from the mill. This field case study focuses solely on the latter, evaluating and documenting the sound level reduction attributed to the installation of the blankets and its potential to reduce the noise dose experienced by ...

End Mills

The reduced shank of this offering of Miniature End Mills Ball Reduced Shank allows for chucking any depth, while its long length design allows for deep cavity machining. CNC ground from solid carbide, this tool was engineered to maximize rigidity during machining operations. Reduced straight shank allows any chucking depth.

The Effect of Ball Size Diameter on Milling Performance

the other mills, as previously mentioned ball mills have a very low efficiency in terms of utilizing the energy generated towards particle size reduction. The diameter of the balls used in ball mills play a significant role in the improvement and optimization of the efficiency of the mill [4]. The optimum rotation speed of a mill, which is the ...

Ball Mill Principle, Construction, Working, Merits, Demerits

Ball Mill Principle, Construction, Working, Merits, Demerits, Appliions, Sunil Bakliwal D. D. Vispute College of Pharmacy, Pharmaceutical engineering

End Mills

End Mills Ball. These reduced neck end mills feature long flutes for deep pocket milling, and are stocked in either 2, 3, or 4 flutes, each offered with an AlTiN coating option for added lubricity and increased wear resistance. SFBM and MMBM manufactured to improved cutter diameter tolerance (H8) for mold making.

Effect of mill type on the size reduction and phase ...

· Air jet milling is found to be the most effective in reducing particle size from a d 90 of 37 µm to µm compared to planetary ball milling ( µm) and single ball milling ( µm). XRD and TEM studies confirm that the planetary ball mill causes phase transformation to the less desired αAlumina resulting in a notable decrease in surface area from m 2 /g to m 2 /g as ...

A Review of Methods for Synthesis of Al Nanoparticles ...

Mechanical milling as a solid state synthesis usually performed using ball milling equipments that generally divided to "low energy" and "high energy" egory based on the value of induced the mechanical energy to the powder mixture [13]. The objective of milling is to reduce the particle size and blending of particles in new phases.

Planetary Ball Mill PM 100

Planetary Ball Mills are used wherever the highest degree of fineness is addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and ...

MCQs Test on Size Reduction.

· Which statement is TRUE for Ball Mill? If the machine is rotated at low speed the balls collide with each other and no or negligible size reduction takes place. If the machine is rotated at very high speed the balls rotate along the cylinder wall due to .

Ball Mill Loading

The starting point for ball mill media and solids charging generally starts as follows: 50% media charge. Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free space. Add to this another 10%15% above the ball charge for total of 23% ...

Planetary Ball Mill PM 100 CM

Planetary Ball Mills are used wherever the highest degree of fineness is from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and ...

(PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING SIZE ...

ball mill is used. · ... the use of the modified hammer mill drastically reduced the nonuniformed particle size associated with most hammer mills as well as eliminates the use of burr mill by ...

Calculate the Reduction Ratio and the Number of Milling ...

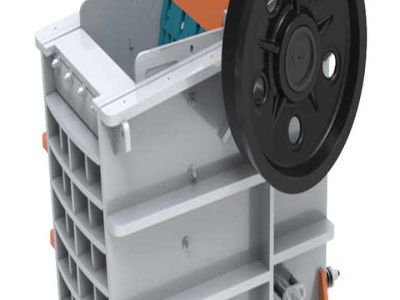

· Before going to the total reduction ratio, I find it useful to mention some typical values of reduction ratio for the most used comminution devices. Jaw Crusher 3/1 to 6/1 Gyratory crusher 6/1 to 8/1 Cone crusher 5/1 to 7/1 Impact crusher 6/1 to 10/1 Rod mill Up to 100/1 Ball mill Up to 1000/1

Size

Size reduction increases as the number of rotations and time taken for ball milling increases. Meshes of larger aperture should be used in sieving to obtain a complete curve of particle size distribution. Some particles were lost when transferring them out of the ball milling, which results in lighter weight obtained after ball milling. Experimental result reported showed that the grinding ...

Reduced Neck End Mills

These ball profile end mills are engineered for excellent performance in light profiling, High Efficiency Milling (HEM), and . . . 6 Flute Corner Radius Variable Pitch Reduced Neck (Aplus) The reduced neck geometry of this variable pitch end mill with 6 flutes provides maximum strength in .

Ball Mill Explained

Ball mills are usually designed with a maximum reduction factor/ratio of 60:1 although it is possible to achieve reduction ratios of up to 70:1. The electric drive for a ball mill should be able to handle loads where the ball mill is charged by up to 45% with balls.

Size reduction and homogenization with ball mills

Size reduction and homogenization with ball mills RETSCH Product Navigator Milling Jaw Crushers Rotor Mills Cutting Mills Mortar Grinders Disc Mills Ball Mills – MM 200 – MM 400 – PM 100 – PM 200 – PM 400 Sieving Assisting Fast and powerful grinding for unlimited appliions RETSCH ball mills are suitable for a wide range of ...

12 Ways To Reduce Cutting Vibrations On Cnc Milling ...

Today, I've compiled 12 ways to reduce the cutting vibration of CNC milling machines in the hope that it will help you all! 01. Use sharp inserts to reduce the cutting force of CNC milling machines. Clamp inserts are divided into coated and uncoated inserts, and uncoated inserts are usually sharper than coated inserts because if the inserts ...

Wet Grid Ball Mill

The ball mill is composed of the main part such as a feeding part, a discharging part, a turning part, a transmission part (a reduction gear, a small transmission gear, a motor, and electric control). The hollow shaft is made of cast steel, the inner lining can be replaced, ...

Latest Posts

- كسارة كسارة كسارة كسارة كسارة مخروط محطم

- معدات المحاجر الأدب

- الحصى في هنتنغتون ، إنديانا

- شراء النحاس محطم في ماليزيا

- بولي كلوريد الفينيل بو حزام ناقل آلة الضغط

- كوريا الجنوبية مطحنة الكرة الصانع

- عمودي طحن الهندسة

- هيدروليكي مخروط محطم فت

- معدات تجهيز المعادن سعر محطم

- عيوب طاحونة رقيق

- غوجارات الحجر المورد

- ما هو حجم كسارة الفك 600x400

- كيفية الحصول على اقتباس حيدر سحق المعدات

- المواصفات القياسية للسيارات كسارة الفك

- جبيرة الأضراس ليلا

- Influences On Strength Of Rock

- Cost Of Polymer Grinding Machine In Kenya

- Australian Used Portable Gold Trommels

- Crusher Uae Dealer Stone Quarrying

- Manganese Ore In South Mining Industry

- Crusher Nutmeg Grinder Priced

- Flow Chart Of Smelting Of Copper Ore

- Energy Saving Gold Mining Ore Fine Crushing Ball Mill

- River Sand Gold Mining Equipment

- Rangkaian Mesin Lizenithne Grinding Mill

- List Of Plants Of Crushing In Uttar Pradesh

- Contoh Gratis Dari Memorandum Dan Artikel Asosiasi Pertambangan

- Material Grinding Diameter

- High Quality Washing Powder Vibrating Screen

- Disadvantage Of Ball Mill Equipment