Internal Taper Grinding Machine

Cylindrical

The Okamoto IGM 15 NCIII/NCII Internal grinding machine with single or twin spindles. Standard touch screen software with 10step grinding program for plain bore, taper and contour grinding with 2axis control. High precision is further optimized via thermally stabilized infeed ball screw. FEATURES . Internal cylindrical grinding machine for bore lengths up to 150 mm. Single spindle or Twin ...

Internal Taper Grinding Machine

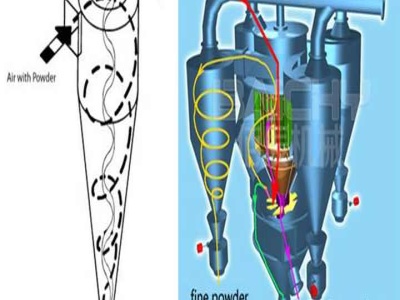

Internal taper grinding solving taper grinding machine diameter id grinding machines, like shown in figure 1a and 1b, are used to issues can then occur during the id grinding process that negatively affect part quality from the truing device can create a wheel od that has taper get more. Grinding Machines Irem Sen . This grinding machine has an ...

how do you cut an internal taper??

· · If this taper is small enough that a 3/4 boring bar won't fit you might consider grinding a piece of HSS to bore it. I've used boring head tools for lathe boring and they worked for me until the holes got too small, at which point I would grab a .

Cylindrical Grinder | MachineMfg

The universal cylindrical grinding machine also has an internal grinding attachment that can grind the inner and outer tapered surfaces with large taper. However, cylindrical grinding machines are less automated and are only suitable for small batch production and repair work. The internal grinding wheel has a high spindle speed and can grind the cylindrical and conical inner bore surface ...

Grinding Machine: Types, Parts, Working Operations (With ...

Internal Grinders (Chucking, Planetary, and Centerless grinders) Special Grinding machine; Floor or bench grinder: Floor or bench grinder is a small type of machine used in the labs where a small workpiece has to grind. For example, when we manufacture a singlepoint cutting tool for a lathe machine we use to manufacture by floor or bench grinder.

China Internal Grinding Machine

This machine is a highprecision internal grinding machine. It is suitable for grinding cylindrical holes and tapered holes with a taper angle not greater than 60º, as well as the inner and outer end faces of the hole. It is suitable for singlepiece, smallscale grinding with a wide range of parts Highprecision grinding for mass production.

Multispindle grinding machine

AZ Universal grinding machines range has been designed to fulfil the requirements of a wide range of appliions that combine external, internal, face and taper grinding... Compare this product Remove from comparison tool

Internal Grinder

INTERNAL GRINDING MACHINES Flawlessly Designed for the Most Meticulous Machining Operations PARAGON reaches new dimensions with the latest generation of CNC internal grinding machines. The Internal Grinding machine has efficient and reliable programming of grinding and dressing cycles suitable for mass production of shaft, rods .bushing and cylindrical workpieces with precise .

Precision Internal ID Grinding

Our Precision Internal Grinding Department can also grind faces, tapers, and radii. Our Cylindrical Grinding Department is also capable of grinding multiple features of a part on one chucking. The benefits of grinding multiple features of a part on one chucking are many. Those benefits include; fewer setups, less wasted time taking parts in and out of the machine, and runout ...

Shaft grinding machine

Universal grinding machines range has been designed to fulfil the requirements of a wide range of appliions that combine external, internal, face and taper grinding of components such ... Compare this product Remove from comparison tool

Cylindrical Grinding Machine RS 700 For Efficiency and Economy

Grinding spindle Motorized spindle Ø 170 x 370 mm Power S6 60% 14 kW Speed infi nitely 1,000 to 7,500 min1 / 250 Hz Torque const. S6 60% 27 Nm up to 5,000 min1 Grinding wheel Ø max. 350 mm Internal taper HSK 80E Cutting speed <140 m/s Workpiece spindle Internal taper ISO50 Speed max. 3,000 min Torque max. 17 Nm Machine Total connected load ...

Machine taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power male member of conical form (that is, with a taper) fits into the socket, which has a matching taper of equal angle.. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools.

Internal Grinding Machines

Internal Grinding Machines. Home » Grinding Machines. Overview Types Data Options Service. WEMA SI solves simple and complex internal grinding tasks quickly and efficiently. A multisettable internal round table and a work headstock are guided to the μm. As with all our machines, SI is scalable and is adapted to your needs through a specific mounting for the great ...

Internal Grinding Machine Manufacturers and Suppliers ...

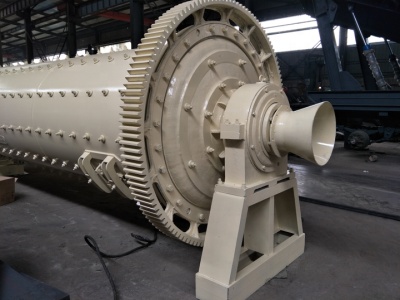

Internal grinding machine of model M250A The machine tool is used in the grinding of the smallbore inner hole, stepped hole and taper bore. The machine tool utilizes the layout of the headstock for fixation, the workbench reciproing, and the grinding wheel rack for feed...

Home | Ohori Grinding

At Ohori Grinding, we fulfill requests for parts that other manufacturers cannot machine, particularly in external and internal grinding as well as taper grinding, which is extremely difficult. We work together with our partner companies to manufacture and prototype complete parts. We process rare metals such as iridium . V grooves, R grooves and polyhedral angles are possible. Machining of 1 ...

GRINDING PROCESS

Internal grinding machine ... Used for grinding tapered work Grinding wheel, regulating wheel, and work rest remain in fixed position Work fed in from front up to fixed stop Grinding wheel and regulating wheel often dressed to required taper, Assistant Professor, Department of Mechanical Engineering, BSACIST, Chennai 48. Advantages of Centerless Grinding There is no need for ...

Internal cylindrical grinding machine

internal cylindrical grinding machine RIG150CNC. for tubes CNC 2axis. internal cylindrical grinding machine. RIG150CNC. Features Equipped with FANUC color screen, the latest technology in digital control systems. The table motion is driven by servo motor to .

Tool Grinding Machine WZS 70 For universal appliion

Grinding wheel Ø max. 203 mm Internal taper HSK 50E (2 sides) Workpiece spindle Internal taper ISO50 Speed standard (optional) 30 (1,200) min1 Torque max. (optional) 60 Nm (100 Nm) Machine Total connected load 15 kVA Supply voltage / Frequency 400 V / 50 Hz Machine (basic) W x L x H 2,120 x 2,680 x 2,420 mm

Regrinding a spindle taper.

· Have Grinder, Will Travel*—*Grinding spindle tapers in the machine" with onsite, inplant, mobile, precision grinding equipment to reduce downtime, runout and teardown. Re grind the work/tool holding arbor or grind the machine spindle ID, or both? One would think Spindle Grinding Service could grind an arbor simple as pie but their site does say so. They should post that for in .

Internal Grinding | BB Precision Engineering

Internal Grinding 500mm Dia x 500mm deep BB Precision have dedied Internal Grinding machines which allows us to grind intrie internal work including multidiameter and tapered bores. We have in house capability to manufacture special jigs enabling us to hold items which would otherwise be difficult to hold in a chuck or on a permanent magnet.

Internal Production Grinding Appliions | UNITED ...

The S122 is a CNC production internal cylindrical grinding machine for small to mediumsized workpieces in small and largescale production. The machine has a swing diameter of 220mm ("). Fritz STUDER AG was formed in 1912 and manufactures grinding machines for internal and external cylindrical grinding for small and middle sized work pieces.

Latest Posts

- كسارة الفك الخاص خام التنجستن

- طاحونة بدون البول

- الصين مصنع فاصل المغناطيسي

- الصين ارتفاع ضغط ريموند المكثف

- محطم التكلفة

- كم هو محطم المحمول

- صناعة المطاط آلة طحن

- أو تبحث عن صانع القهوة

- شنغهاي كسارات الهند

- تأثير محطم قدرة تغذية مدخل 400

- أفضل كسارات الصخور المتحركة

- حساب استهلاك محرك CR الفحم مفرغ

- الصين كسارات هيدروليكية

- كسارات الحجر القديم للبيع في دلهي

- شنغهاي ذروة تأثير محطم معدات كاملة

- Small Gold Ore Crusher Repair In Nigeria

- Sander Conveyor Belt Options Fine Woodworking Knots

- German Silica Processing Plant Acid Wash

- Steel Crushers Prohormone Price

- Specification Of Inches Jaw Crushers

- Rock In Coal Mine

- Mill For Sale Durban

- Ancient History Clay Crusher

- Profit Margins In Stone Crusher Business Scmmining

- Design For Tertiary Crusher Circuits

- Saudi Rock Crusher Companies

- High Quality Cone Crusher Machine For Breaking Hard Stone

- Mobile Concrete Crusher With Metal Recycling

- Crusher Manufacturers In The United States Of America

- Hill Coal Trucking Co