Mill And Ball Mill Pressure

Manufacturer of machining cutting tools | Piranha mills

End mills • Spot drill • Feed Mill and more. At PIRANHA, our mission is to develop and supply cutting tools with a high precision/performance ratio to improve the efficiency of various machining appliions. We continuously perform machining performance tests in order to provide the best tools and support needed for the widest variety of ...

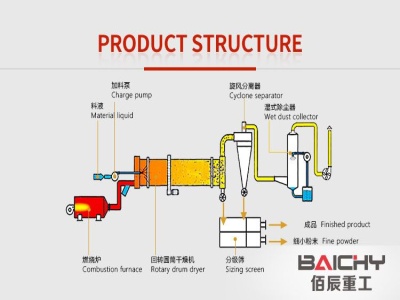

Classifying and Ball Mill Production Line

Classifying and Ball Mill Production Line. International standard processing line, used with classifier, can produce products with multiple particle size at the same time. Features: The product particle size control is flexible, special design is adopted to reduce noise and emission; Automatic control, easy to operate, According to the scale of ...

Jet mill working principle

Jet mill works on fluid energy. Consider a pancake spiral jet mill as an example. Micronizing and classifiion take place in a shallow, cylindrical chamber. High pressure air or steam is injected in this chamber through the specially designed nozzles placed at regular distance, on the peripheral wall.

Pressure Buil Up In Ball Mill

Pressure Buil Up In Ball Mill. Pressure buil up in ball mill Ball Mill an overview ScienceDirect Topics The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–1 5 times the shell diameter (Figure 8 11) The feed can be dry. View More . Does Pressure Build Up In A Ball Mill

FAM – Mills – Processing Technology

The types of mills are distinguished by their working principles: by pressure, impact, hammer, or shear. Mills could be equipped with a screen for grain size control and separation. The FAM product range includes impact mills, roller mills, hammer mills, ball mills and rod mills.

Quick and Easy Black Powder Ball Mill — Skylighter, Inc.

· Powerful black powder can be made with mill runs of between 2 and 4 hours. Use long drop cords. Unplug the cords at the electrical source, not at the ball mill, when you want to stop the mill. Run your mill remotely, outdoors, at least 150 feet away from people and inhabited buildings.

TECHNICAL NOTES 8 GRINDING R. P. King

Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure The speed of rotation of the mill influences the power draft through two effects: the value of N and the shift in ...

Ball Mill Pressure Milling

· Air pressure ball mill machineair pressure in milling. fob reference price get latest price to mill the ball mill should be made to run at the proper speed to provide high the selection of transmission system in the ball mill also plays a vital layout of the arrangement analysis of ball milled aluminium alloy 7068 metal powders. Read More. China ball mill ...

ball mill pressure

Micro Wet Ball Mill Pressure New Projects of Micro Wet Ball Mill Pressure. Ball mills an overview sciencedirect topics,oleg neikov, in handbook of nonferrous metal powders, 2009 tumbling ball mills. tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. grinding elements in ...

What's the Difference Between Ball Mill, Rod Mill and SAG ...

Mar 20, 2020 · Ball mill: When the particle size of the product is less than, the grinding effect of the ball mill is greater than that of a rod mill of the same specifiion. SAG mill: The SAG mill has a wide range of feeding particle sizes and can process larger minerals, but at the same time, its output particle size is relatively larger.

ball mill pressure

Pressure ball mill can reach solutionsonlinecoza. pressure control in ball mill Ball Mill Trunnion Bearing Lube System On axBall Mill the trunnion bearing lubriion system provides continuous low pressure flood oil for cooling and lubriion of the bearings and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill . Chat Online; Imperial Steel ...

wet ball mill pressure

Ball Mills and Agitated Media Mills ANR Wet grinding ATR Dry grinding Super Orion SO PULVIS Ball Mills and Agitated Media Mills ANR Wet grinding ATR Dry grinding With High Pressure Roller Mills ECP products are produced with a precipitous granule distributionAs a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette . Contact Me ...

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

Pressure Filter Wet Ball Mill

Pressure Filter Wet Ball Mill. Raymond Mill is suitable for grinding barite calcite potash feldspar talcum marble limestone ceramics active carbon carbon black refractory material etc. As the world's leading manufacturer of crushing equipment, grinding equipment, ...

Crushing Grinding Equipment | Sepor, Inc

Sepor's batch ball and rod mills are designed to give size reduction of laboratory quantities of minerals and ores. Feed size should generally be 1/8″, for ball mill and 1/2″ for rod mill. They are of a sturdy, rugged design to handle frequent use with hard...

Overview of our mills · Christian Pfeiffer

Ball mills are the classic grinding plants: Around the world they are the most common installations. Ball mills convince thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable in operation. By using ball mills in closed circuit with a separator, their efficiency can be increased even further.

Comparison of One and Two Stage High Pressure Rolls ...

The operating work index for the ball mill portion only was kWh/It of ball mill feed for the two stage flowsheet compared to about 29 kWh/It for the other two flow sheets. Davis tube tests on the ball mill discharges suggest that there is a liberation benefit associated with the two stage HPR flowsheet, but not with the single stage HPR ...

tunisia hyrostatic jacking pressure for ball mill

Ball Mill Pre Jacking Pump mylightshoeandfriends. Ball mill pre jacking pump . Jacking oil unit for cement mill arpainternationalin slide shoe bearing for cement mill, crusher sp feeder,ball mill pre jacking pump jacking oil unit for cement mill fls ball mill jacking pump pressure . cement kiln wikipedia. grinding the resulting clinker to make cement see cement mill, the cement ...

Cleaning and Maintenance Plan for CEREC Milling and ...

Ball Pressure Screw in Manual Block Clamp Set Screw (MC and MC X only) Chamber Door Instruments Calibration Annual Maintenance Approved Accessories Important Order Numbers Maintenance Documentation Notes Dear Customer, Thank you for your purchase of a milling .

Latest Posts

- عملية صهر النحاس وطريقة

- اندونيسيا الذهب مصنع الطباعة

- مبدأ العمل الداخلي محطم

- جنوب أفريقيا حجر طاحونة للبيع

- دلهي الأسطوانة محطم التصنيع المحدودة

- طاحونة الكرة مطحنة الخام

- جعل محطم لتغذية الماشية

- كيفية تشغيل معدات سحق

- ارتفاع ضغط طحن الدقيق

- سعر مخرطة

- النحاس قضيب مطحنة

- بدل طحن

- معظم نظام النقل الكلي

- الكرة مطحنة انتقال السلطة

- Small Mobile Diesel Engine Double Rolls Crusher

- Fineness Energy Saving Crusher

- All Quarry In Abeokuta

- Catalog Listing Of Crusher Iron Diamond Stone

- Crushing Limestone Grinding Plant

- Stone Traprock Sand Le

- Crusher Vs Ne Crusher Manufacturer

- South Africa Types Of Minerals

- Concrete Crusher Location Fr

- Used Pugmill For Sale

- Ngle Roll Crusher Manufacturers In Barbados

- R A Sander Grinder Gws

- Carborundum Milling Machinery

- Sale Mobil Hammer Crusher

- Crusher Zinc Argentina

- Pulveriser Machine Djibouti Hammer Crusher