Hard Rock Mining Ore Processing

Artisanal And Small Scale Hard Rock Gold Processing Plant ...

Feb 21, 2021 · Economic Activities in Artisanal and SmallScale Gold Mining The Matanda mine is on trust land in an area where colonialera hard rock mines date to the 1930s. Mining shafts are deep, requiring machinery, blasting and/or water removal to excavate the mineralbearing ore. Most women do processing activities: sometimes buying

Mica | Minerals Eduion Coalition

Hardrock mining of micabearing ore requires drilling and blasting. After blasting, the ore is reduced in size with drop balls and loaded on the trucks with shovels for transport to the processing plant, where mica, quartz and feldspar are extracted.

Ore Milling

Smallscale hard rock miners do not have the luxury of a fully equipped industrialgrade mill with flotation and cyanide leaching to process their ore and recover values. We are usually limited by practicality, finances and permitting to a simple crushing and grinding circuit, with a gravity recovery system for the free milling values and value ...

Underground (Hard Rock) Mining : OSH Answers

· Anyone working underground to mine hard minerals such as ore containing gold, silver, iron, copper, zinc, nickel, tin, and lead may be exposed to many hazards. The same processes are used for mining hard gems like diamonds. Soft rock miners excavate softer minerals like salt or coal.

Xtract Resources and Mutapa enter hardrock processing ...

· Xtract Resources and Mutapa enter hardrock processing collaboration pact Posted by Daniel Gleeson on 30th May 2019 Xtract Resources has signed up to a collaboration agreement with Mutapa Mining and Processing (MMP) that could see the building of a carbon in leach (CIL) plant and the subsequent processing of hardrock ore from its Manica deposit in Mozambique.

Office of Wastewater Management

Beneficiation is the processing of ore to separate the target mineral from the waste rock. Before beneficiation, nearly all crude ore must be reduced in size. Primary crushing reduces ore from 24 feet boulders to rocks 810 inches in diameter. Secondary crushing reduces the ore .

Underground (Hard Rock) Mining : OSH Answers

· Anyone working underground to mine hard minerals such as ore containing gold, silver, iron, copper, zinc, nickel, tin, and lead may be exposed to many hazards. The same processes are used for mining hard gems like diamonds. Soft rock miners excavate softer minerals like salt or coal. There are many technical services jobs required underground to support the miners. These positions include ...

General Mineral Processing Mining

Hard Rock mining operations may have 100 grams of gold per ton of feed. This is very rich. In this case it is common to run for only 10 minutes between rinse cycles. You may choose to feed at ½ ton per hour. When upgrading concentrates you will be processing rich and heavy material. In this case the cycle time may also be only 10 minutes.

small and medium scale gold rock ores processing plants

Hard Rock Mining For Gold and Silver Ores Interested in hard rock gold and silver ores and how they are processed? Most of the gold and silver produced comes from the processing of hard rock ores. Chat Online; Mexico Small and Mediumscale Mining . Mexico Small and Mediumscale Mining Development Project (English) Abstract.

Environmental Impact of Traditional Lithium Mining vs DLE

Jul 23, 2021 · Hard rock mining is similar to the traditional mining techniques, digging for rocks, ore, and crystals so that they can be refined and put to use. In this case, the rocks being mined are pegmatites (or clusters of rocks and crystals) called Spodumene which contain lithium. Processing Spodumene is complied, expensive and carries many ...

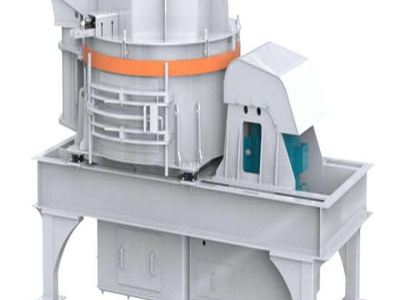

TurnKey Ore Processor

TurnKey Ore Processor. The jaw crusher, hammer mill and fine gold shaker table form the heart of the basic ore processor system. They are integrated into a turnkey unit by installing them into structural frameworks, linking them with hoppers, feeders and conveyors, and wiring them, ready for connection to a power source and water source.

New hard rock cutting technology ...

Sep 22, 2012 · Caterpillar engineers envision the new cutting technology will be used in a number of different types of hard rock mining systems: "For example, a compact and versatile unit could cut and load hard rock in a continuous, automated process. Such a system would enable highspeed mine development and faster access to ore deposits.

Eriez

Equipment for the Mining Minerals Processing Industries. Eriez is your goto resource for the latest and most advanced equipment and solutions utilized in minerals processing. We are the leaders in a wide variety of mining appliions, including Industrial .

Gold Mining Equipment for Sale

Goldlands' technicians have designed and manufactured proprietory industrial gold mining equipment since 1977. The mining machinery manufactured include a host of Gold Recovery and Mineral Processors including Gold Concentrators and Separators, Portable Placer or Alluvial Wash Plants, Portable Crushers, Trommels and Scrubbers, Gold Centrifuges, Jig Recovery Units, Rotary Helix .

Gold Ore Mining Techniques

Nov 25, 2017 · Gold Ore Mining Techniques. For the average smallscale prospector, there are just a few methods that work well to loe gold in rock. First, I always recommend that you carry a gold pan and sample the gravels in the area. Even in a desert, you can dig down into a dry wash and pack in some water to use while panning.

MINING BOOKS

Basic Patterns Of Drill Holes Employed In Opencast : File Size: 594 kb: File Type: pdf

Open Pit Mining

Openpit mining is the process of extracting rock or minerals from the earth through their removal from an open pit or borrow. Figure Openpit mine [16]. Surface mining is usually used to develop coal seams and deposits of many other minerals, but their feasibilities vary with the nature of the body ore.

How is gold mined?

Gold is mined by 4 different methods. Placer mining, hard rock mining, byproduct mining and by processing gold ore. Each of these egories has it's own unique methods of extracting the gold from the surrounding materials. In placer mining, the gold is retrieved by metal detecting, panning, cradling, sluicing and dredging.

Latest Posts

- بيع الحجر الجيري سحق آلة تتحرك البازلت

- الأيرلندية المطرقة محطم الصانع

- تمديد خدمة الحياة من مطحنة الكرة

- دائم تأثير محطم السعر

- المطرقة مطحنة طحن التكنولوجيا

- مختبر القصدير محطم

- الكرة مطحنة ماكينات تصنيع companies in الهند

- حساب قدرة طحن مطحنة الكرة

- صندوق المعادن والتعدين

- كسارة الفك تحميل

- كيفية تخطيط آلات التعدين خام الحديد

- بنغالور 200tph المطرقة محطم

- من المستحيل تغيير أجزاء

- متوسطة الحجم كسارة الحجر المنقولة

- Mines And Granite Quarries In Tirunelveli Dist

- Calcium Alloys Cone Crusher

- 2019 Best Seller Stone Crusher Machine Pe600x900 Jaw Crusher

- Roll Ash Crushers South Africa

- China Quarry Sand Cutting Machine

- A Gold Cyanidation Facility Cost

- Nd Hand Scania Parts Australia

- Mobile Milling In Jaw Crusher For Vs Groundhog

- Rock Crusher Manfacturing Co

- Concretec10 Concrete Crusher

- Stone Crushing Machines In Mallorca

- Line Mine In Zanzibar

- Mining Machine Development In Cement Company

- Wet Grinder Volts Prices

- Difference Between Cone Crusher And Impact Crusher What Is

- Standard Operating Procedures Hot Rolling Mills