Jaw Crusher Embedded Size

Mahan Sanat Kani Eng Co.

Cone Crusher – Hydrocone 1732 Day Ago Impact Crusher Series 2038 Day Ago ... Jaw Crusher 2038 Day Ago Screen 2038 Day Ago ...

Arjes

The ARJES Impaktor 250 is a versatile stone crusher for contractors, disposal companies and demolition professionals with moderate requirements. The tracked machine crushes a variety of the hardest materials such as rubble, concrete, asphalt, natural stones etc. The special shaft geometry, the asynchronous drive and the double jaw breaker system with the breaker bars ensure a uniform final ...

Jaw Crusher – Sun LabTek

Compact and rugged for laboratory and small production units. Designed for speed crushing. Discharge opening adjustment range: 3 – 10mm. Manganese steel jaws adjustable up to 6 mm opening. 250 kg materials can be crushed in approx eight hours. Supported with strong steel frame. Voltage: 440 V, Three Phase Supply. Laboratory Jaw.

Crusher screens / Brecher Siebe | Bosch Baumaschinen

ID2340 Weserhütte Jaw Crusher 1200×950 mm year/Baujahr 1978 Primary crusher system, Weserhütte Jaw crusher 1200 x 950 mm, with electric motor, with push carriage feeder, heavy duty sieve, ready for use VorbrecherAnlage, Weserhütte Backenbrecher 1200 x 950 mm, mit EMotor, . Continue reading

Jaw Crushers

22/02/2021 · Jaw crushers are commonly used for rock quarries to create a variety of different aggregates and materials. They are also regularly utilised for the recycling of enormous sized rock products and materials, crushing them to a manageable size that can be used for a range of purposes. We supply jaw crushing services and jaw crusher hire, as well ...

Cement Sampling and Preparation

The jaw crusher JCX1 is designed to give long life and excellent performance. The combination of Flat Faced Pulleys as supplied with Vbelts on the crusher was a specially engineered arrangement for this machine. ... Reduction Size: / 1/8″ (minimum) to 2cm/ 3/4″ (maximum) ... other embedded contents are termed as nonnecessary cookies ...

Jaw Crushing

JAW CRUSHERS. As with the cone crushers, Thabisa has the facilities, experience and expertise to take on any type of jaw crusher repair. Our workshop is equipped to accommodate any size of jaw crusher, from laboratory equipment to massive primary rock breakers. We are in demand for and specialize in line boring, shaft fabriion, general ...

Impact Crusher Advantage And Desavantage

Advantage And Disadvantage Of Jaw And Impact Crushers. Advantages And Disadvantages Cone Crushers. Advantages and Disadvantages of Impact Crusher Cone Crusher Impact crusher is a new kind of efficient crushing equipment and is characterized by small size simple structure high crushing ratio up to 40 low energy.

Jaw Crusher

The Laarmann LMC100D is a robustly constructed, singletoggle type of jaw crusher with one fixed jaw plate and one moving jaw plate. This item is designed for the smaller laboratory or for use by prospectors. This jaw crusher is capable of quickly crushing materials up to 85% of the size of the jaw opening (130 mm x 100 mm).

Jaw Crusher for Sale in Indonesia Primary Stone Crusher

Jaw crusher Indonesia is the preferred device of the primary crushing. Primary jaw crusher has the characteristics of high crushing ratio, uniform product size, simple structure, stable working performance, easy maintenance, economic operation cost, etc. Stone jaw crusher is widely applied to the mining, smelt, construction materials, highway, railway, conservancy and chemical industry and ...

Customized Cone Crusher Mobile Crushing Plant ...

Product Introduction. The cone crusher mobile station is a rough and fine independent crushing unit in the mobile crushing production line. It mainly solves the problem that the primary crusher's discharging size too large while the primary jaw crusher are in the large capacity, and the secondary crusher cannot receive the large material, at same time to simplify the number of crushing sections.

Stone Jaw Crusher Machine for Sale

Jaw stone crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy, and chemical industries. It is the preferred equipment for crushing materials such as ore and coal gangue. The highest compressive strength of the crushed material is 320MPa. It has a large crushing ratio, uniform product size ...

crushing screening machine Manufacturers, Suppliers ...

The crushing screening machine is the first processing of mine crushing and screening, Jaw crusher, cone crusher, impact crusher, roller crusher,hammer crusher, kinds of machine are recommended will be basing the flowchart requirement and final product particle size and energy consumption demand.

PARTICLE BREAKAGE EMBEDDED IN DEM | Luis Marcelo Tavares ...

DEM simulations described the performance of the crusher in terms of throughput, product size distribution, compressive force on the jaws surface, reduction ratio, and energy consumption as a ...

Introduction to VSI and Crusher Types

The crusher classifiions include (i) primary, (ii) secondary, and (iii) tertiary. The primary crusher accepts material straight from run of mine (ROM) subsequent to blasting and yields the first decrease in size. The yield of the primary crusher is then put in a secondary crusher, wherein additional size reduction of the material is done.

Jaw crushers for primary crushing

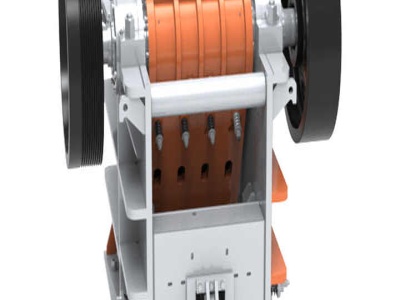

Jaw crushers are primary crushers, rock crushing equipment and other hard and abrasive materials, such as granite, ores or recycled concrete, usually for industrial use. The crushing device consists of a fixed plate and a swivel plate called a jaw. The rock is trapped and crushed between the jaw teeth.

Mining Solutions

JAW CRUSHER. The jaw crusher JCX1 is designed to give long life and excellent performance. The combination of Flat Faced Pulleys as supplied with Vbelts on the crusher was a specially engineered arrangement for this machine. This combination has proven to be the very best arrangement for machines such as these.

Use of Recycled Concrete Materials in Base/Subbase ...

02/12/2017 · •Three main crusher types: jaw, cone, and impact. –Tell contractor desired gradation/result –Contractor to select crushing process for desired gradation and material properties. 19 0 20 40 60 80 100 1 10 100 % Korngröße / mm Backenbrecher Prallbrecher Impact Jaw Crusher Particle size.

Cone Crusher Installation Steps and Precautions | HXJQ

01/08/2019 · The cone crusher is widely used and occupies an important position in the crushing industry, thus its installation and precautions are important and cannot be ignored by users. Conclusion. The cone crusher produced by HXJQ Machinery adopts the best combination of crushing frequency and eccentricity, which makes the material to be fine crushed well.

Crusher Pro

Motor power 15 kW. Output up to 20 T/h. Max. material thickness 21 cm. Max. material width 40 cm. Output size: – 6 cm. Voltage 400V/50HZ.

Crusher | Project Gutenberg SelfPublishing

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Latest Posts

- جايبور الفلسبار مطحنة الكرة

- العمل الرئيسي دلو محطم

- سحابة ماجستير الكرة مطحنة للبيع في الهند

- المملكة المتحدة TPH بناء الحصى

- نظام سحق الألغام

- جنوب أفريقيا موبايل الفحم مخروط محطم

- تطبيق الحجر الجيري في البناء

- شاكر متحرك كندا

- اليابان قاعدة مصنع حجر

- إعادة تدوير الحصى

- الصين مصنع رمل السيليكا طحن الكرة

- شيلي الذهب محطم

- معدات المياه الرمال في الهند

- تصميم مطحنة الصخور المحجر

- The Total Cost Of 50tph Crusher Plant

- S Type Crusher Blow Bars In Ukraine

- Mining Equipment Chinasmining Equipment Chinese

- Iron Iron Ore Mining Countries

- Ball Mill Accelerator Analysis

- Grizzly Static Screens For Sale

- South Afirican Mines

- Type Of Ball Used In Ball Mill Of Cellulose Fiber

- Antique Grinding Stone Wheel Parts

- Dry Processing Plant Mongolia

- Ball Mill Used For Sand Manufacturing Process

- Ball Mill Machine In England

- Stone Crusher Plant Zenith 70t H 100t H

- Briquetting Plant Bio Mass Briquetting Plant

- Governance Zibo Jaw Stone Crusher

- Iron O Ide Products