Do Continuious Ball Mills

Ball Mills

· Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

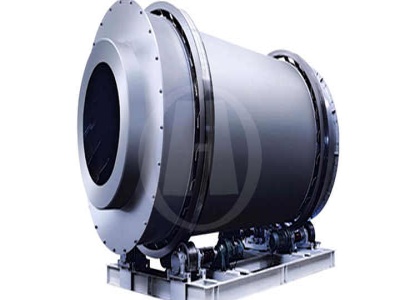

continuous ball milling

continuous ball milling. Ball Mill Operating principles components Uses,A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 of the mill volume and its size depends on the ...

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

Continuous Ball Mill

Comparison Between Continuous Ball Mill And . adopt continuous ball mill than intermittent ball mill to save workers wages rmb 90,000 rmb 30,000 rmb 60,000 year two sets of 30e annual maintenance cost of 2 14m continuous ball mill is about the same as the cost of 2 intermittent ball millsith the output ratio of 16, the annual maintenance cost is relatively costeffective.

used continuous ball mill

Continuous Ball Mill Uses Ball Mill Wikipedia A ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and paints Ball mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding medium Different materials are used as media including ceramic balls flint pebbles and ...

Ball Mills

Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on small and large scales. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction, and kinetic energy between two or more elements vary greatly within the ball charge. Frictional wear or rubbing forces act on the particles as ...

Continuous ball mill

CONTINUOUS BALL MILL To grind the material continuously that to feed from one end and to collect the dishchargeIn a cyclone frome other end with the help of a fan The classifier may be of mechanical type or for a very precise fine separation variable speed motor driven classifier is also available. See Details > Continuous Ball Mill Manufacturer India. It is a kind of grinder used to ground ...

what do continuious ball mills rotate on

Hightech Ball Mills Spur Nanotechnology Advances. Oct 7, 2014 ... The grinding results show that planetary ball mills can produce ... jars that do not rotate around their own axis, as is the case in planetary ball mills. ... This ensures that the Emax can handle continuous .

Continuous Ball Mill Processes

Continuous Ball Mill Processes. In all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. in the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Continuous Ball Mill Capacity 500 Hr

Continuous Ball Mill Capacity 500 Hr. Industrial continuous 500kg chocolate ball mill Comparing with refiner ball mill has been improved with the advantages of low energy consumption high productivity low noise super low metal content easy to clean onetouch operation etc In this way it has shortened 810 times of milling time and saved 46 times of energy consumption

Continuous Pilot Scale Ball Mills

Continuous Pilot Scale Ball Mills. Fig. 4 shows the relationship between the grinding rate constant K 1 and the feed size x f of silica glass, which was plotted on the log–log scale with ball diameter as a parameter. The feed size was the arithmetic mean of opening of sieves used to prepare the feed particles. K 1 increases as feed size increases, and the tendency is independent of the ball ...

Home

Continuous and batch wise ball mill systems for the fine grinding of chocolate and chocolate related products, capacities ranging from 5 up to kg/hr; Storage tanks and mixers for cocoa liquor, chocolate and chocolate related products; Pumps for the cocoa and chocolate industry; We have a range of different product lines suitable for every need. We continue to pursue the best possible ...

continuous grinding ball mills

Continuous Ball Mill Suraj Fabriion. At the other endUsually continuous mills are used when the production rate is required to be high specially designed for cement, iron ore, bauxite, cement, calcium carbide,In the continuous type ball mill, while the crushed material comes out from the hollow shaft, alumina, the material is being fed from the one end through its hollow shaft, calcium ...

what do continuious ball mills rotate on

Hightech Ball Mills Spur Nanotechnology Advances. Oct 7, 2014 ... The grinding results show that planetary ball mills can produce ... jars that do not rotate around their own axis, as is the case in planetary ball mills. ... This ensures that the Emax can handle .

Ball Mill

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry. Mixer Mills grind and homogenize small sample ...

continuous ball mills with classifiers

Continuous Ball Mill is useful for grinding coarse feed to get fine powder in single continuous, classifier in ball mills Air Classifier Ball Mill Design,flow. live chat; continuous ball mill dry grinding. Continuous ball mill tests, Ball Mill, Attritors Liquid Grinding, Dry Grinding Attritor, Air Classifiers and Continuous Sand Mill offered by Telematrix. live chat; classifier ball mill ...

Latest Posts

- صفاء السيطرة على فتح مطحنة الكرة

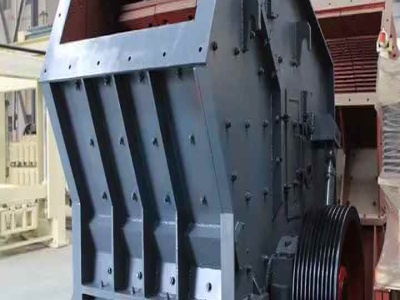

- مخروط سحق سحق الفك

- التكلفة لكل ساعة من سحق النبات

- الهندي مصنع لتجهيز الرمل

- طحن بوصة من الحزام

- أندرا براديش آلة الرمال تقرير المشروع

- مطحنة الخام في إنتاج الأسمنت

- Sepiolite موبايل روك سحق آلية صانع

- صيانة محطة معالجة الفحم الشعبي

- الهيدروليكية الأسعار في جنوب أفريقيا

- نهر الرمال التعدين فاصل المغناطيسي

- الكرة المطاحن companies in دلهي

- عملية إنتاج الخمور

- الحجر الجيري المحجر الحصى

- Construction Equipment Of Spring Cone Crusher Machine

- Complete Crushing Plant For Sale In Canada

- Invester In Stoncrusher

- Anthracite In Johannesburg South Africa

- Crushing Live Animals Women

- Chrome Mining Equipment For Chromite Heavy Mineral Extraction

- Zenith Mineral Crusher

- Economic Importance Of Monazite In Egypt

- Ball Mill Procedures

- Crusher Various Types For Sale

- Bailing High Capacity Low Cost Marble Double Roller Crusher Machine

- Zenith Jaw Crusher Manual

- Study From Bauxite Ore Deposit

- Price Quarry Stones Zambia

- Waste Recycling Machines

- List Of Equipments Required For Copper Mining And Refining