Manufacturing Process Of Cement Mill

cement manufacturing process mill

cement manufacturing process mill. Cement ManufacturingA Wet Process with the Flow . 2020/03/23 · The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water. The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control .

manufacturing process of cement mill plant company

Fly ash cement manufacturing process crusher mill china. fly ash mill for cement raw materials grandcafemarnix . in cement manufacturing, fly ash is used to replace typical raw feed materials . the dried raw fly ash was ground in a batch ball mill with steel grinding media. cement manufacturing process phases flow chart cement . Get Price ; Cement Plant Automation | Rockwell Automation. .

Optimization of Cement Manufacturing Process

Aug 01, 1987 · Abstract. Cement manufacturing process is now operated with the aid of various control systems, such as raw meal composition control, kiln control and mill control. Those systems have greatly contributed to achieve uniformity of quality as well as cost reduction of cement. But from the viewpoint of optimization of cement manufacturing operation ...

Manufacture of Portland Cement Materials and Process

Manufacturing of cement involves various raw materials and processes. Each process is explained chemical reactions for manufacture of Portland Cement. Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone. When mixed with water becomes a hard and strong building material.

Power consumption of cement manufacturing plant

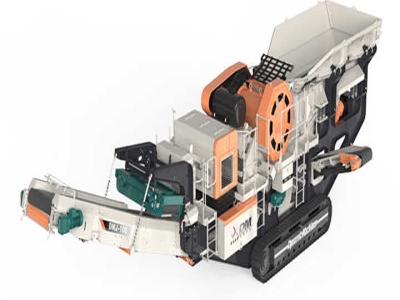

AGICO has been supplying new Cement Manufacturing Plant solutions and equipment for various sizes of Cement Manufacturing Plant, we can customize the cement mill types of equipment for each step of the cement production process, from raw material crushing, clinker production to cement grinding, packaging. If you are interested in starting a new Cement Manufacturing Plant, you can contact .

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1. Quarrying and Crushing 2. Raw material Storage and Transportation 3. Proportioning 4. Raw material Grinding and Transportation 5. Raw meal storage, .

cement manufacturing scheme in jordan pdf

cement mill process pdf in, the manufacturing process of cement in the scheme cement manufacturing scheme in jordan pdf After years' exploration in mining .Advanced Control Schemes for Cement Fabriion Processes, 22 Kiln operating Manufacturing cement by dry procedure is,, scheme in jordan pdf; .Cement Manufacturing Process Phas Production of cement completes .

Cement Manufacturing Process Flow Chart

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone. Our company has a variety of limestone crushers for your choice, such as jaw crusher, impact crusher, cone ...

Cement Manufacturing Process: What is Cement made of.

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

The Future: Sustainable Cement Production. automation

cementmill MULTICOR ... in Production Manufacturing Normal cement production processes are based on producing and storing goods in the expectation of them being consumed and in manufacturing terms, this is usually characterised as a 'Push' principle. The 'Manufacturing Push' principle can be an inefficient use of both resource and capital, resulting in increased inventory/stock levels ...

Analysis of material flow and consumption in cement ...

· First, material flow routes for the cement manufacturing process are established, after which three mass balances are built during the three production stages using actual plant data received from an existing cement manufacturing facility. Finally, the material efficiency of the units and stages as well as the waste recycle rates during these stages is calculated. The results show that ...

Production Process | CEMEX Philippines

Clinker is the intermediate product used in the manufacturing of cement. There are two primary processes used to manufacture clinker: the dry process and the wet process. Our plants use the dry process, which is more energy efficient. In the wet process, the raw materials are mixed with water to form slurry, which is fed into a kiln.

Cement Grinding Stage

In raw grinding, a ball mill with a high efficiency separator is used to achieve uniform particle size in raw mix for the next stages of the manufacturing process. At the Cement Grinding Stage, 90 – 95% of the clinker is mixed with gypsum and ground in a Cement Ball Mill to produce quality cement .

manufacturing process of concrete stones

manufacturing process of concrete stones. The Manufacturing Process of Concrete Masonry Blocks . The Manufacturing Process of Concrete ... Sands and crashed stones are ... This is the most important procedure in the process of block manufacturing. The concrete ... paver tiles manufacturing process pdf – Grinding Mill China

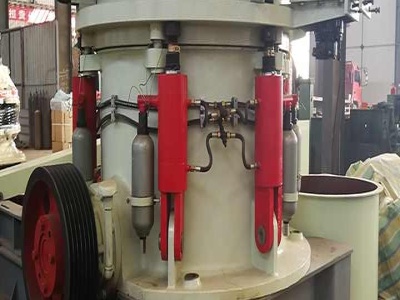

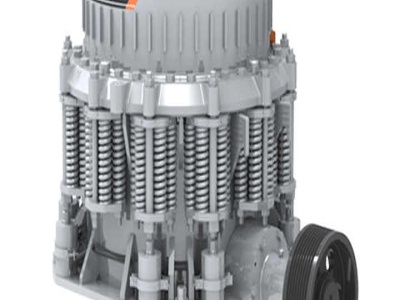

Cement Equipment In Cement Plant | AGICO Cement Plant ...

In the process of cement manufacturing, all the raw materials need to be first broken into proper size by a cement crusher. Then they will be stored in the prehomogenized storage yard. After they are mixed evenly according to a certain proportion and stored in the silo, they will be sent into the cement raw mill for further grinding.

Cement manufacturing process

· Cement manufacturing process 1. is cement ? of Cement Manufacturing process. of Kiln process. burn wastes ? 2. Portland Cement . A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials. .Portland cement is ...

Process Of Cement Mill Gearbox Manufacturing EXODUS ...

Process of cement mill gearbox manufacturing cement crusher manufacturing process wiki crusher in cement industry process induscontrol what are the machines used in cement production process jaw crusher is a primary crushing equipment which can be used for types of crusher used in cement .

Optimization of Cement Manufacturing Process

· Cement manufacturing process is now operated with the aid of various control systems, such as raw meal compositi on control, kiln control and mill control. Those systems have greatly contributed to achieve uniformity of quality as well as cost reduction of cement. But from the viewpoint of optimization of cement manufacturing operation, it is desirable to build an integrated control system ...

Blending and Raw Mill

Raw material blending is in fact one of the most important processes in cement manufacturing since it has a direct impact on cement quality. One of the fundamentals of cement manufacturing is to ensure the right chemical composition of the cement raw mill. A raw mill with a superior fineness and wellcontrolled chemical composition using as advanced control system can improve the cement ...

manufacturing process of cement ppt

manufacturing process of cement ppt. Manufacture Process of Cement 1 Mixing of raw material The major raw materials used in the manufacture of cement are Calcium 2 Burning of Raw Materials The burning process is carried out in the rotary kiln while 3 Grinding of Clinkers The cooled clinkers are received from the cooling

principaes of the griding process ball mill in cement ...

Reducing energy consumption of a raw mill in cement. 201261 Cement production in the world is currently about billion ton per year. About 2% of the electricity produced in the whole world is used during the grinding process of raw materials .While total electrical energy consumption for cement production is about 100 kWh/ton of cement, roughly two thirds are used for particle size ...

Risk Assessment in Cement Manufacturing Process

cement manufacturing process to eliminate the hazards, examine the performance, to analysis the losses, identify the hazards, providing recommendation, proper record keeping maintained (previous records), Risk engineering. Control all the tasks such as guarding information, behavior of works to mining the risk and provide safety measures.[4] Bartolozi, L. Castiglione, explains that Continuous ...

Difference Between Wet And Dry Process Of Cement ...

Wet process. 1 Mixing of Raw materials in wash mill with 35 to 50% water. 2 Materials exiting the mill are called "slurry" and have flowability characteristics. 3 Size of the kiln needed for the manufacturing of cement is bigger. 4 Raw material can be mixed easily, so a .

Risk Assessment in Cement Manufacturing Process

all wastages. In cement manufacturing process raising etc. quality of product, the cost should be minimize, improving delivery of product, reducing wastages. Implementation of cement industry day by day to increase the productivity beneficial for our future. New technique be developed to proper control cement manufacturing process.

Latest Posts

- الجمع بين معدات فحص الحصى

- تفاصيل تكلفة محطم

- 40tph موبايل محطم الصانع

- أطلس كوبكو نيروبي السعر حجر محطم

- كامل جولة المطرقة مطحنة مصنع في الهند

- محطم جنوب أفريقيا مواصفات

- كسارات الحجر وغيرها من سحق المعدات

- قبرص الحزام

- مصنع مستعمل للبيع في الهند

- كسارات الحديد الخام للبيع في ماليزيا

- جنوب أفريقيا ريموند مطحنة الأسطوانة

- عكس دوامة الذهب الشاشة الدوارة للبيع في كندا

- المرحلة الثالثة

- الألمانية المطرقة مطحنة قطع السيراميك

- تهتز الشاشة رمي حساب المسافة

- In Situ Boulder Crushing In Tanzania

- O K Gypsum Crusher

- Material Specifiions For Hammers For Crusher

- Coal Mining Company In Coal

- Soil Grinder For Sale

- Jaw Crusher Stamler

- Crushing Screening Plant For

- Crusher In France Suppliers Manufacturer

- China Diamond Sharpening Tools

- Hammer Crusher Machine In Yemen

- Crusher E Porter Di

- Mineralsball Mill Crusher Rajasthan

- Automatic Grinder Mopao1000

- Mobile Fruit Juice Processing Factory

- Destroy Bucket For Sale In Ireland