Recommended Maintenance For A Grinding Mill

How to do the Ball Mill Repair and Maintenance Work?

Aug 25, 2020 · 1. Ball Mill Daily Inspection. It is required that the staff on duty should be familiar with the structural performance, safe operation specifiions and maintenance skills of the ball mill, and check and record the ball mill according to the time and items specified by the spot inspection standard and the spot inspection card.

Laboratory Grinder | Laboratory Mill | Sample Preparation ...

The UDY Cyclone Sample Mill is powered by a 1/2 hp AC/DC universal 115V; 10,000 rpm full load (16,000 rpm no load) The grinding ring has tungsten carbide abrasive particles on a steel base. Ground material is collected in 120 ml glass bottles, fabric bags, or other containers.

Coffee Grinder vs Grain Mill – 6 Key Differences to Help ...

A coffee grinder is recommended for those folks who can not afford an expensive grain mill at their homes right now. If you are looking for an affordable kitchen appliance that can comfortably grind flours into coarse to medium grind level, then coffee grinder or a blender is the best option for you.

Recommended way to clean the INSIDES of a used Magic Mill ...

Jun 03, 2015 · Greetings y' baking newbie here. I found a used Magic Mill III Plus at a thrift store (for 4 !!!) and am taking my first steps into milling wheat into flour. I'm getting new filters for it (from ) which appears to be all it needs (besides some industrial ear protection equipment) :) . My question is regarding cleaning the INSIDES of a used

UDY CYCLONE LAB SAMPLE MILL Documentation

Spare parts that are recommended: Screen(s), Grinding Rings, Impellers 8 mm, Sample Collection Bottles 120 ml, Antistatic Soln, and Air Outlet Filter Media. INSTALLATION OF THE GRINDING RING ALWAYS TURN YOUR MILL OFF AND DISCONNECT FROM THE ELECTRICAL SOURCE

The 10 Best Pepper Mills in 2021

Jun 30, 2021 · Grinding pepper is a lot about feel and comfort, so if the size doesn't work with you, it's not going to feel right. Refilling Mechanism . While all pepper mills rely on gravity and a grinder to mill the peppercorns, the way you refill the peppercorns differs depending on the mill.

RME

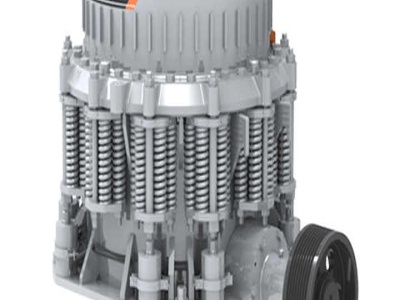

Mill liners are designed to be sacrificial linings to protect grinding mill shells and to enhance the movement of the charge for optimum throughput and grinding performance. A Mill Relining Machine is a purpose designed machine used to remove and place liners in grinding mills.

What to look for when buying a grain mill?

With a stone grinder, much finer flour can be produced. Since mills made of natural stone are quite expensive and intensive for maintenance, a corundumceramic grinding mill has become established on a broad line. These are highquality compacted, durable and extremely robust bricks made of corundum ceramic.

A daily checklist for chipper and grinder maintenance ...

Mar 27, 2018 · The next area for inspection is the mill where the grinding and chipping of material takes place. On a grinder, always check the tips of the grinding bits to make sure the cutting edges contain sufficient carbide to make it through a shift. A worn bit is unproductive and should be turned or .

China Basket Mill Batch Grinding Machine for Pigment ...

delivery, our professional engineer will offer onsite guidance debugging free of charge, according to different characteristic of materials, to set up the operational parameters of the mill and ensure optimal grinding quality equipment running status; the warranty period, we provide maintenance and maintenance service, only ...

Hammer Mill For Fine Grinding Maintenance Manual

Hammer Mill Technical Data 22", 38" and. maintenance of hammer mill Grinding Equipment Manufacturer. maintenance of hammer mill machine Ore Crusher Repair and maintenance of hammer mill. First, we have to understand the main structural hammer crusher : Hammer crusher ...

CEMENT GRINDING COURSE

CEMENT GRINDING COURSE. The training aims to identify and understand necessary known and unknown information towards the grinding system's completed cycle, whether it is a ball or vertical mill. Throughout the course, the lectures are supplemented with exercises and case studies, allowing the participants to relate the course material to ...

How to Sharpen A Machete

Make sure nothing around your grinding wheel can interfere with the path of the blade. Using a grinding wheel can damage or overheat the blade, so experience is recommended. Dousing the blade repeatedly with water will keep the blade cool. As long as the metal does not overheat and lose its temper you will be fine. Mill Files and Hones

Care and Use Guide – Salt and Pepper Mills Plus

Apr 28, 2021 · Zassenhaus: Dry spice and herbs for the spice mills. The nutmeg grinder needs whole nutmegs. AdHocs: Dry spice and leaf herbs for the spice mills. Cleaning and Maintenance. Q How should I clean my mill? PEUGEOT: Do not put your mills in the dishwasher. Clean the body of the mills with a soft, dry cloth. Never immerse the mill in water.

Grinding and Milling Systems Course

Grinding and Milling Systems Course. A sixweek course designed to take students through the complete cycle of raw material grinding and preparation, clinker grinding, milling and separation cycles. Ball mills and vertical milling technologies will all be included with operator training on improved grinding techniques, cost saving strategies ...

Optimization of Cement Grinding Operation in Ball Mills ...

Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as well as improve the run factor. Consistent quality and maximum output with lower specific power consumption results in lower ...

Fine Grinding

Corrugated rotor mills and pin mills. –. For very fine grinding (< 10 μm) of dry plant material, we use a device made up of a cylindrical rotor turning at 3,000 − 1 in a stator with a slightly bigger diameter. Rotor and stator surfaces are equipped with parallel corrugations along the vertical axle. Fines are pulled toward ...

Wichita GMC Grinding Mill Clutches for Fertilizer Plant ...

Wichita Clutch, along with its local distributor partner, recommended the installation of reliable Model 342 Grinding Mill Clutches (GMCs) on all three mills. Since Wichita was not a wellrecognized brand in the Chinese chemical phosphorite industry, a customer tour of a nearby facility where Wichita clutches were successfully installed was ...

What are the differences between ball mill and rod mill ...

Mar 08, 2021 · Ball mill and rod mill are suitable for different materials. 1. Selection by material's hardness. Ball mill has a strong adaptation of material, and it is suitable for grinding hard materials, such as slag, iron ore, copper ore, etc. Rod mill is suitable for grinding brittle material, such as rare metals. 2.

Grinding and Polishing

Grinding of magnesium alloys carries a high fire risk unless strict precautions are taken against accidental ignition and in the removal and drenching of dust. High standards of cleanliness and maintenance are required in all exhaust ducting to prevent risk of fire and also to keep ventilation working efficiently.

Maintenance Of Vertical Grinding Mill EXODUS Mining machine

Handle Germany Maintenance Procedure For Grinding Mill. To handle grinding mill maintenance at two 202048 has signed an 18month servs contract with codelcos chuquicamata mine for grinding mill maintenance encompassing changeout of components for 33 ball mills currently operating in the a0 and a1 plants at chuquicamata.

Latest Posts

- اعتبارات تصميم وتخطيط معدات سحق

- رخيصة طحن الرطب

- كاشف عن محطم

- المعدات المستخدمة في تحضير الفحم

- تعدين الذهب الخام

- مطلوب ليثيوم أيون

- ألمانيا آلة كروتشر

- الفك محطم سعر المصنع

- حجر المطحنة كسارة حجر المطحنة حجر المطحنة

- كسارة المطرقة مطحنة

- مخروط محطم زلق

- الرطب نوع خطي تهتز معدات الفرز

- مزايا استخدام مطحنة الأفقي

- كسارة الفك PE 400

- China Mining Equipment Sayaji Stone Chrusher

- Small Stone Aggregate Crushing

- Dust Collectors For Grinders

- Rutile Roller Mill Supplier

- Machine To Separate Sand London Uk

- Industrial Gold Dry Washing Machines

- Ecentric Crank Shaft Stone Crusher 400x250 Sand Making Stone Quarry

- Crushed Stone Rate In Norway Stone Crusher Machine

- Surface Grinder For Sale Cal

- Boron Stone Category

- Crawler And Mobile Crusher Plant Manufacturers In Saudi Arabia

- Gold Ore Comminution

- A Detailed Finance Project On The Stone Crusher Business In Bangalore

- Din En 9335 Techstreet Technical Information Superstore

- Rumor Mill Revamped Sonata Due In 2019

- Dynamic Braking For Vibrating Screens