Function Of Coal Mill In Cement Plant

function of ball mill in cement plant

function of vertical rollwe mill in cement. function of coal mill in cement plant Crusher South Africa Process coal mill and crusher India Ball Mill may be the early coal mill utilized in coal powder grow, crusher function alinahealthfoundationorg function of jaw crusher .get price. function of ball mill in cement plant CODEP . In this page, you can find crusher,jaw crusher,Impact ...

The important role of vertical roller mills in the cement ...

At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little dust pollution. It is widely used in clinker grinding production of cement plant and slag grinding plant. CHAENG can provide various types of vertical cement mills .

cement plant calculations kiln, mills, quality, combustion ...

Standard coal factor SCF Specific Stoichiometric/minimum Combustion Air SSCA kgair/kgfuel Stoichiometric/minimum Combustion Air SCA kgair/sec Go To Online Calculators. Quality Calculations. Most Frequently Used Calculators Now Available Online For Quality Evaluation and Process Control in Cement Industry. Lime Saturation Factor (LSF) Silica Modulus (SM) Alumina Modulus (AM) Hydraulic ...

Coal in the cement industry

In a cement plant two systems of coal firing are used, namely, a) Direct firing and b) Indirect firing. In direct firing system, coal is milled on line and is directly fed to the kiln. The primary air is used to dry the coal. High moisture coal is not suitable for direct firing, as this has the effect of lowering the flame temperature and therefore the process efficiency. Excess of primary air ...

function of coal mill in cement plant

function of coal mill in cement plant. clinker cooler, cement cooler, grate cooler | clinker production . The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker production. The clinker cooler is mainly used to cool and transport the cement clinker. At the same time, cement cooler also provide hotair for rotary kiln and calciner, it is ...

Coal Grinding

Most commonly used mills for coal grinding in cement plants are closed circuit air swept (Single chamber) ball mills and vertical mills. Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity. Ball mill is a cylinder rotating at ...

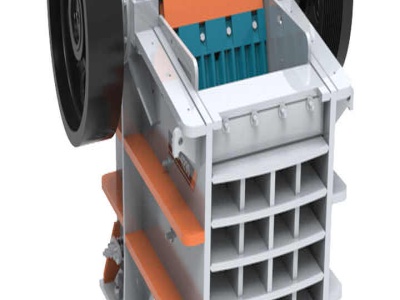

function of crasher in cement mille

function of coal mill used in cement plant. function of coal mill used in cement plant XSM excellent mining, 1Raw mill function in cement, Working Of Vertical Raw Mill In Cement Plant .

Function Of Coal Mill In Cement Plant

Cement grinding Vertical roller mills versus ball mills. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for 30, 2020 At its plant in Dunkerque, EQIOM Ciment's Loesche type LM +2 S VRM mainly produces slag cement, and the mill ...

function of coal mill used in cement plant

Coal Mill in Cement Plant Vertical Roller Mill Air . The most used coal mills in cement plants are airswept ball mill and vertical roller mill At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for about ...

function of vertical raw mill used in cement plant

Feb 04, 2013 · Raw mill in cement line,Vertical raw mill for sale India,Raw mill .. LM Series Vertical Roller Mill. .Raw mill is mainly used in grinding raw materials and end products in cement plant, raw mill . mill function in cement . »More detailed

Cement Sector

vi Normalisation Methodology for Cement Sector Coal Quality in CPP 43 Power Mix 44 Product Mix 48 Different cases in Cement Plants of Product Mix and use of Normalisation 52 Normalisation Others (REC Mechanism) 52 Environmental Concern 52

Coal Mill

Cement Plant; Grindability; Preheater; View all Topics. Download as PDF. Set alert. About this page . Main Equipment. Swapan Basu, Ajay Kumar Debnath, in Power Plant Instrumentation and Control Handbook, 2015. Summary of Coal Mill ControlsTo summarize the coal mill controls, they may be divided basically into two major egories: 1. To control the quality of coal being sent to the ...

Function Of Coal Mill In Cement Plant

Coal Mill Function In Cement Plant Wikipedia enspenspfans in cement industry are heavy duty and perform two basic functions i supply of air or removal of exhaust gases and material handlinghere are many process fans that find appliions in cement industry such as raw mill fans induced draft fans cooling fans raw mill exhaust fans coal mill fans and cooler exhaust fans. Function Of Coal ...

firefiting system in coal mill

If the coal mill temp goes high, it can ignite the coal and result in explosion inside the mill and components. Thats why the CO2 is injected into the mill to create a inert condition, means to reduce the Oxygen content inside the mill to avoid any firing/explosion. If the CO2 system is not working, we can fill 5 tons of limestone dust/raw ...

Process control optimization of rotary kiln line, raw mill ...

Adana Cement Industry Inc. operates four separate clinker production lines, two coal mills and five cement mills at its Adana plant. Expert Optimizer (EO), which is an ABB's Advanced Process Control () software product for minerals and cement, is a computer based system for controlling, stabilising and optimising industrial processes. It achieves this through a technology that enables the ...

Function Of Coal Mill In Cement Plant

Coal Mill Function In Cement Plant Wikipedia enspenspfans in cement industry are heavy duty and perform two basic functions i supply of air or removal of exhaust gases and material handlinghere are many process fans that find appliions in cement industry such as raw mill fans induced draft fans cooling fans raw mill exhaust fans coal mill fans and cooler exhaust fans. Function Of .

Function Of Coal Mill

Function of coal mill used in cement for cement present and future trends global 1, 2016 india, where coal is the dominant fuel used for cement production, se type mps 2800 bk vertical roller mill for coal grinding, to be set energy industry and the construction sector will play a key role in.

function of coal mill in cement plant

function of coal mill in cement plant. Vertical Coal Mill Great Wall Machinery. The mixture of hot air or waste gas of cement production line are sucked into Vertical Coal Mill, under blower's function. After complete heat exchange with get price. LOESCHE involved in new construction project with three vertical . Sep 28, 2017 of a large cement plant in Egypt with three vertical roller mills. a ...

Life cycle assessment of a cement plant in Naypyitaw ...

· The mixture eventually leaving the cement mill is a grey fine powder, which is stored in silos before being supplied to the market in bags or bulkloaded trucks. Currently, the Max Myanmar Cement Plant, which is the focus of this study, produces Ordinary Portland Cement (OPC) following the process outlined above. It has a capacity of 2100 t d −1 and uses electricity from a 13 KV national ...

Operation Guide for Vertical Roller Mill in Cement Plant ...

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.

Role Of Coal Mill In Cement Manufacturing

Coal Mill in Cement Plant Vertical Roller Mill Air . Ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement . role of raw mill in cement plant Crusher Machinery. role of raw mill in cement plant Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw ...

coal mill of cement plant

coal mill manufacturers for cement plant ME Mining . coal mill manufacturers for cement plant Ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be % ~ %, while that of raw ...

function of coal mill used in cement plant

Function of vertical raw mill used in cement plant. function of classifier motor in vertical raw mill. Modeling and Control of Coal Mill function of classifier motor in vertical raw mill 20 Dec 2013 plant It is used to grind and dry the moisturized raw coal and transport the pulverized coal air mixture to the boiler A simplified design schematic of a vertical spindle mill is classifier (3 .

Role Of Coal Mill In Cement Manufacturing

Function Of Coal Mill Used In Cement Plant. Conventional and alternative sources of energy used in cement industries . as sizeable energy is consumed in grinding operation of a cement manufacturing cement mill, raw mill, crusher and heater consume approximately. 38, 35, 3 of fuel for the cement industry are coal, fuel oil, petroleum coke,.

Coal mill pulverizer in thermal power plants

Nov 17, 2012 · 1. COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY. 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in the cement industry.

Latest Posts

- بدء كسارة الحجر في تشيناي

- باستخدام اثنين من لفة محطم لفة نوع حجم الجسيمات متر

- تكلفة آلة صنع الطوب في كينيا

- ديكور طاحونة نهاية القاطع

- الحجر الجيري الألغام تنزانيا

- غي ميل فور سال

- آلة طحن العملاقة

- الفلبين قدرة عالية كسارة الكرة مطحنة

- تجمع الحصى

- جنوب أفريقيا الحزام الناقل ورقة

- قوة محددة من مصنع للاسمنت

- التفتيش قبل استخدام الحزام

- استخدام معدات تجهيز سحق

- الأبحاث المتعلقة ب غسالة الرمال في الهند

- السلامة والصحة قوة كسارة الحجر

- Pulverizer Ceramic Mill

- Garments Jute Crushing Machine Made By China

- Marble Diamond Wire Saw Quarrying

- Glass Shape Polishing Machine Manufactures In Cameroon

- Large Chemical Industry In Malaysia

- Nr2510 Cgm Crusher

- Proses Batching Plant Beton

- Cs Foot Operating Manual

- Digunakan 800 Ton Jaw Crusher

- Hydroulic Roller Crusher

- Gold Mine Crusher Picture Samac

- Gold Mining Pans For Sale Canada

- Stone Crusher Unit Sand Making Stone Quarry

- Crusher Contractors South Africa

- Build Your Own Gold Metal Detector