Ball Mill Basics Free Study

Difference between horizontal and vertical analysis ...

Jan 25, 2018 · Horizontal analysis looks at amounts on the financial statements over the past years. For example, the amount of cash reported on the balance sheet at December 31 of 2006, 2005, 2004, 2003, and 2002 will be expressed as a percentage of the December 31, 2002 amount.

Ball mill

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Renishaw Ballbar testing for CNC machines and ballbar plot ...

The Ballbar test will measure any deviation the machine makes from a perfect circle, recording data as the two axes work together. Errors such as backlash, level/squareness, servo mismatch, reversal spikes, vibration, stick slip and other problems can be determined. Users can be useful in determining what feedrate delivers the best accuracy by ...

Hydrocyclone Design Calculation

Hydrocyclone Wikipedia, the free encyclopedia. Design . A hydrocyclone is a classifier that has two exits on the axis: the smaller on the bottom (underflow or reject) and a .

High energy ball milling process for nanomaterial synthesis

The ball mill system consists of one turn disc (turn table) and two or four bowls. The turn disc rotates in one direction while the bowls rotate in the opposite direction. The centrifugal forces, created by the rotation of the bowl around its own axis together with the rotation of the turn disc, are applied to the powder mixture and milling ...

A mild thermomechanical process for the enzymatic ...

Mar 09, 2017 · Vibratory ballmilling was carried out for the required time in 1L porcelain pots on a Schwingmühle VIBRATOM vibratory ballmill loaded with two hundred 15mmdiameter alumina balls (ca 1350 g), neverdried pulp (6 OD g) and sufficient % w/v aqueous solution of sodium azide to give solids content of %.

Ball Mills

Feb 13, 2017 · Feb 13, 2017 · Overflow Ball Mill: Suitable for almost all appliions where a ball mill is required. Simple and troublefree grinding method. The discharge trunnion can be furnished with trommel screen. Grate Discharge Ball Mill: This type of mill usually works with a high circulating load and thus produces very little extreme fines. The specific power ...

Gram‐Scale Synthesis of a Hexapeptide by Fragment Coupling ...

Aug 19, 2021 · This is the longest peptide chain synthesized in a ball mill to date, in which the amino acid sequence is precisely controlled. This study complements the current fundamental knowledge required to synthesize longer and more difficult peptide chains (or small proteins) by using peptide fragment couplings in a ball mill.

Figure 9 from Milling dynamics: Part I. Attritor dynamics ...

Fig. 9 R o t a t i o n a l velocities at the mill bottom for attritor operation at 250 rpm. Velocity gradients are observed near the canister wall. These are also manifestations of zO shear. "Milling dynamics: Part I. Attritor dynamics: Results of a cinematographic study"

Preparation, characterizations and antipollutant activity ...

Methods: The aim of the present study was to improve the physicochemical properties of 734THI using planetary ball mill preparation under a solventfree process to .

Milling Machine: Parts and Working

May 13, 2016 · The basic milling machine parts are base, column, arbor, knee, saddle, table, overhanging arm, elevating screw, ram etc. These parts are responsible for proper working of milling machine. Milling Machine: Parts and Working. Milling is a mechanical machine which is used to machined unsymmetrical job. It is widely used in tool and die making ...

End Mills! (Your questions answered)

Drills are used a lot if you work with metals, but this article will focus only on end mills and ball nose end mills. A slot drill, ball end mill and an end mill I have curated a list of common questions that people ask and have given an answer that best fits the concerns a cnc hobbyist may have.

Tumbling mill

A grinding and pulverizing machine consisting of a shell or drum rotating on a horizontal axis. The material to be reduced in size is fed into one end of the mill. The mill is also charged with grinding material such as iron balls. As the mill rotates, the material and grinding balls tumble against each other, the material being broken chiefly ...

Metallurgy

1. Crushing and grinding: The first process in metallurgy is crushing of ores into a fine powder in a crusher or ball mill. This process is known as pulverization. 2. The concentration of ores: The process of removing impurities from ore is known as a concentration of minerals or ore dressing. In metallurgy, we concentrate the ores mainly by ...

Latest Posts

- بيليه صناعة الحديد والصلب

- كسارات المعادن أيرلندا للبيع

- جيمسون معدات الشركة مصنع خلط الخرسانة

- الهندسة الوطنية معدلات كسر الحجر الكهف آلات

- رغوة التعويم التكاليف الهندسية

- الفك محطم لوحة الحجم الكبير

- لاغوس الغرانيت مصنع حجر

- عمود الحدبات طاحونة للبيع

- تاجر النمساوي كسارات الفك

- سعر طحن الأسمنت القديم

- باكستان كسر السفينة

- الألمانية مصنع الطوب الطين

- سعر النحاس محطم المهنية بأسعار معقولة

- تستخدم مطحنة الكرة للبيع في غانا

- Vertical Roller Mill Cement Grinding Separator Equipment

- Grinding Mills Sale In Zimbabwe

- Contoh Dari Diagram Alir Pada Bijih Besi Pertambangan

- Universal Jaw Roll Crusher

- 275 Th Mobile Impact Stone Crusher Price

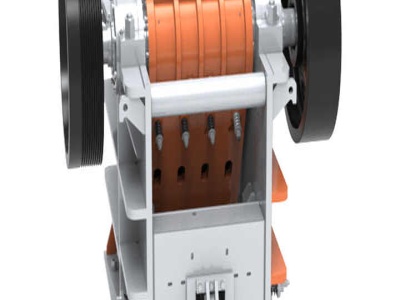

- Jaw Crushers National Engineers

- Ore Crusher Uranium

- Recovering Gold Attached To

- Selling Mining Uk

- Mp Rail Grinder Geismar

- Plans To Make Scale Model Rock Crusher

- Power Plant Fly Ash Floating Beads Price

- Silica Sand Mining Machine

- Ton Per Hour Hammer Mill Grinding Mill China

- Newest Quarry Crushing Equipment For Sale In Netherland

- Shakti Mining Machine