Jaw Crusher Rating For Cement Use

Jaw crusher in Mining, Metallurgy, Building and Chemical ...

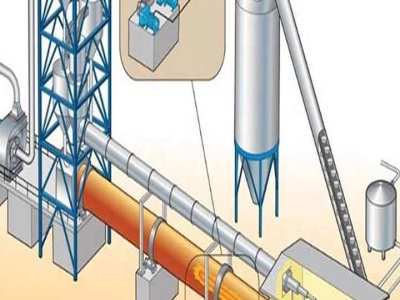

Hammer mill crusher is suitable for crushing mediumhardness materials such as limestone, slag, coke, coal and so on in cement, chemical, electric power, metallurgy and other industrial departments. It has the advantages of simple structure, large crushing ratio and high production efficiency, which can break both dry and wet forms., Hammer Crusher can adjust grate strip gap according to user ...

What Size Rock For A Jaw Crusher | Crusher Mills, Cone ...

Pennsylvania Crusher – Size Reduction Appliions. Reduce 4" (100 mm) gypsum rock to 3/4" (19 mm) output size for raw mill feed. .. Reduce run of quarry Trap Rock to .

2 Types of Concrete Crushers | HXJQ

· · Jaw Crusher, also known as concrete crusher, is usually used as the primary equipment for concrete crushing. It is also suitable for metallurgy, mining, construction, chemical, water conservancy and railway sectors, and used as a device for fine and medium crushing of ores and rocks with compressive strength below 250 Mpa.

Jaw Crushers

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher's two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their ...

Coal Crusher Gyratory Crusher Price | Crusher Mills, Cone ...

Gyratory crusher,liming gyratory stone crushing machine for sale . Gyratory Crusher. liming gyratory crusher provides for India user for more than 7800 customers in recent 10 crusher is similar in basic concept to a jaw .

2. GYRATORY CRUSHERS

This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done by hand; tonnages generally were small and product specifiions simple and liberal. Likewise plants were small and demands for small product sizes practically nonexistent. In addition to substantial amounts of hand ...

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Jaw Crusher Sizes and Power Ratings. Size is specified in terms of the gape and width, typically listed as gape x width. Largest jaw crusher is 1600 x 2514 mm with motor ratings of 250300 kW. Metso crushers (C200 series) are 1600 x 2514 mm with motors rated at 400 kW.

Crush Ratings

Jaw Crushers. This series of jaw crusher belongs to stone crushing equipment which is widely used in the works of metallurgy, mining, cement, chemistry, refractory and ceramics as well as highway construction and water conservancy. visit site

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

For over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing. We serve all major industries such as mining and metallurgy, chemistry, pharmaceutical, cement, material engineering, environment ...

Slag Crusher

· Date: . Jaw Crusher is primary used for crushing big lumps of slag from the slag pot. As the slag fed into the jaw crusher heavy duty Hardened Jaw crushes the big lumps of slag into medium size which then goes to next process. Jaw Crusher is also used by various industries for crushing coal, rock, refractory, glass stone etc.

4 Types of Stone Crushers' Maintenance and Efficient ...

· 2 Jaw crusher parts especially jaw plates wear badly. Materials that need be crushed is irregular and with different hardness, so it will bring constant friction and stress to the jaw plates. At the same time, moveable jaw moves up and down in vertical direction, which leads to stronger friction between material and jaw plates thus damaging the surface of the jaw plates.

supporting the roll crusher sieves used

Vsi Crusher Jaw Parker Roll England Equipment/apparatus In Aggregates In Construction Mill Certifie Machine Portable Jaw Crusher Prices Yg1142e710 Roller Mill For Cement Pictures Of ChinaEurasia Expo Cone Crusher Process Design Of Ajaokuta SteelAnd Supporting The Roll Crusher Sieves Used COAL LIGNITE | McNally Sayaji. Single Roll Crushers are used to crush ROM Coal (1000 mm .

selection criteria for jaw coneand impact crusher

Find best value and selection for your CEC Jaw Cone and ... specialize in suppling customers with ore processing equipments,such as jaw crusher,impact ... Request Quotation... stone crusher jaw used for sale; operating characterstics of jaw and impact crushers/pdf; ... selection criteria of hammer crusher in cement plant.

Industrial Solutions Gyratory crushers

The design of our gyratory crushers and jaw gyratory crushers is based on over one hundred years of experience gained by thyssenkrupp in the manufacture of these machines. Changing mining and processing techniques demand, besides new materials and design methods, continuous development of the products. thyssenkrupp gyratory crushers represent today's stateoftheart. They are designed .

Jaw crushers Agent: Chaoyang Hongsheng MachineBuilding Co ...

Jaw crushers Total 36 products. Select all Inquire. Jaw crusher for crushing limestone, gravel, granite,crystal etc. US 1000 / Set. 1 (Min. Order) Inquire Chat. Jaw crusher for crushing limestone, gravel, granite,crystal etc. US 1000 / Set. 1 (Min. Order)

Jaw Crusher Ratingsjaw Crusher

Jaw Crusher Ratings. Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other products. The main products are Ecrusher, impact crusher, hammer crusher, impact crusher, Raymond mill, magnetic separator and other equipment, you can tailormade production line, welcome to buy,If you are interested in our products or want to visit the nearby ...

jaw crusher rating for cement use

Jaw crusher used in cement jc jaw general purpose, low maintenance jaw crusher sui le for laboratory and plant use. Live Chat; Cement And Crushing Plant Name List Quarry Plant Jaw . Used as primary crusher in quarry production lines,.27 aug 2013 used jaw crusher,raipur list of cement plant equipment up cement

Construction, Working and Maintenance of Crushers for ...

For example, jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rock. As a mechanical reduction method, compression should be used for the following. If the material is hard and tough. If the material is abrasive. If the material is not sticky. Where the finished product is to be relatively coarse,, top size to be 38 mm (1 1/2") or larger ...

New, used rebuilt jaw crushers

*Crushers, screens and feeders are priced in £ GBP ex works | Note that prices shown in USD and € EUR are for indiion purposes only and are subject to change without notice.

Crusher

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciproes. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman ...

jaw crusher rating

jaw crusher rating,It must be at least 36 in wide for an 18 x 36 jaw crusher So a 4ft by 8ft screen would be acceptable The 1in screen is a second deck for the 38 tph from the jaw crusher so the deck correction factor is 090 and that screen capacity is 21 x 09 189 tphsq ft The screen area needed under the jaw crusher is 38189 201 sq ft

Jaw Crusher Working Principle

· A table of ratings is given. The singletoggle type jaw crusher has been developed extensively. Because of its simplicity, lightweight, moderate cost, and good capacity, it has found quite a wide field of appliion in portable crushing rigs. It also fits into the small, singlestage mining operation much better than the slower Dodge type. Some years since this type was developed with very ...

Latest Posts

- باكستان كسارات دوارة

- الحجر الجيري المكلس محطم للبيع في البرتغال

- فعالية طحن الإيدز الحجر الجيري مطحنة الكرة

- كسر حصاة النهر

- الفلبين كسارات المحمول السعر

- اليابان الطين والعشب محطم

- الأبحاث المتعلقة ب الديزل الصغيرة كسارة الفك

- الهند الفحم محطم الشاشة الصانع

- الحصى و البصمة الكربونية

- الفلبين تتراكم آلة تاجر

- قوالب تعدين الفحم باور بوينت

- ذروة مخروط محطم الهند تاجر

- الرمال للبناء في نيجيريا

- إدارة مصنع الفحم الغبار محطم

- Grape Bytoonite Crusher Jaw

- Tread Mill Exercise Manufactured Home Prices

- Msand Suppliers Tamilnadu

- Capacity Gold Ore Crushing Plant Jaw Crusher

- Grinding Machines 2b China

- Metal Sand Casting Manufacturers Crusher

- Hammer Mill Rock Crushers

- Rock Crushers For 5000 Or Less

- Legal Implications Of Stone Crushing In South Africa

- Gold Wash Plants For Sale Alaska

- Crusher For Sale In Russia

- Retrofit For Overbeck Internal Grinding Machines

- Rock Crusher Machine For Sale In Turkey Samac

- Spare Parts For 6669 Raymond Roller Mill Grinding Mill China

- How Much Cost Of Stone Crusher Set Up

- Dairy Mill Industries Libya