On Layout Of Pulverized Mill

animated video pulverized coal mill

ppt on layout of pulverized mill system. animated video pulverized coal millcasaldigioia Pulverized Coal Feeding Handling System YouTube Feb 23 2018 Watch how a Pulverized coal feeding handling system ensures proper airfuel ratio and coal finesse consistency for better combustion United Nations Development Programme India .

How accurate primary airflow measurements improve plant ...

· Primary airflow has a major impact on the efficiency, capacity, and cleanliness of pulverized coal–fired generation. Inaccurate measurements that .

Online coal flow control mechanism for vertical spindle mills

20/03/2006 · BACKGROUND OF THE INVENTION. 1. Field of the Invention. The present invention relates to pulverized coal boilers and, more particularly, to a mechanism for directing coal flow trajectories to the corresponding outlet pipes of the vertical spindle mill with negligible effect on the preexisting primary air flow distribution, the mechanism comprising an array of individually adjustable flow ...

Power Plant Engineering Laboratory Manual Course Code: ME407

to pulverized coal combustion. The pulverized coal is obtained by grinding the raw coal in pulverizing mills. The various pulverising mills used are as follows: 1. Ball mill 2. Hammer mill 3. Ball and race mill 4. Bowl mill. The essential functions of pulverising mills are as .

Ball And Race Mill Pulverizer Layout Diagram

ball mill diagram – Crusher Price ... Belt Conveyor Control Crusher Plant Layout .SAG MILL diagram – OneMine Mining . of iron ore fines carried out in a ball mill;. A schematic diagram of the Minimill test ... a medium speed ball and race mill, ... island were developed to design the spatial coal in a coal mill ...

Power Plant Engineering Laboratory Manual Course Code: ME407

to pulverized coal combustion. The pulverized coal is obtained by grinding the raw coal in pulverizing mills. The various pulverising mills used are as follows: 1. Ball mill 2. Hammer mill 3. Ball and race mill 4. Bowl mill. The essential functions of pulverising mills are as follows: 1. Drying of the coal 2. Grinding 3. Separation of particles ...

Thermal Power Plant General Layout

Thermal Power Plant General Layout. · Here now we going to discuss only steam power station or steam power generation plant and all other power station in next coming have the advantages, disadvantage, layout, working principle of steam .

Appliion and Advantages of Pulverized Coal Vertical Mill

· 6 Small floor space, compact layout, system equipment with light weight and low investment for civil construction. 7 The residence time of materials in the vertical mill is short (23 min), which is easy to automatically control the ingredients and chemical composition of products. Pulverized coal vertical mill has obvious advantages in grinding efficiency, energy consumption, environmental ...

Field and CFD Study of Fuel Distribution in Pulverized ...

Field and CFD Study of Fuel Distribution in Pulverized Fuel (PF) Boilers ... Changing the load of coalmills and fuel type at the same time (, different types ... Fig. 4 Layout of the firing system of a PF boiler that uses a technology that can vary concentrations of fuel streams .

What Is The Best Choice For Pulverized Coal Manufacturing ...

Aug 25, 2021 · Recently, HCM received news from frontline customers that the pulverized coal production line with a daily output of more than 100 tons built by HCM has been put into operation and reached the production standard! The whole grinding production line of the project is designed by HCM, fully combined with the user's site conditions, with reasonable process design, compact layout, .

UNIT1 THERMAL POWER STATIONS Introduction

as in paper mills, textile mills, sugar mills and refineries, chemical works, plastic manufacture, food manufacture etc. The steam for process purposes is extracted from a certain section of turbine and the remaining steam is allowed to expand in the turbine. Alternatively the exhaust steam may be used for process purposes. Thermal stations can be private industrial plants and central station ...

Long Gap Mill for Pulverizing and Milling | Rotormill

Particles are pulverized to small sizes by interparticle collisions induced by very high turbulence within the mill. The pulverizing action is generated by an internal rotor that spins at high speeds. Heavyduty bearings provide stability during the pulverization process.

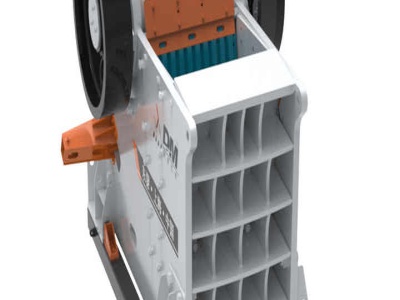

Crusher Plant Pdf

Crusher Plant Pdf Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Crusher Plant Pdf, quarry, aggregate, and different kinds of minerals.

Diagram Of Coal Mill In Power Plant

Single Line Diagram Of Coal Mills . Pulverised Mill Diagram Mining Quarry Plant. Gulin is a major coal crusher manufacturer and supplier for power plants, 130 tons pulverized coal mill process block diagram of coal fired thermal power diagram of coal mill gold ore crusher. Read Now Flue Gas Desulphurization Fgd Plant 2 X 600 Mw Coal.

Types of pulverised coal firing system

The pulverising mill grinds the coal at a steady rate irrespective of boiler feed. 2. There is always some coal in reserve. Thus any occasional breakdown in the coal supply will not affect the coal feed to the burner. 3. For a given boiler capacity pulverising mill of small capacity will be required as compared to unit system. Disadvantages . 1.

USB2

A bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body ( 2 ) having a central axis; and a bowllike grinding table ( 3 ) mounted on a shaft ( 4 ) rotatable about said central axis, cooperating with a plurality of grinding rolls ( 6 ). The airmill is provided with multiple entry openings ( 17′, 17″; 18′, 18″; 21, 25 ...

Layout Of The Raw Mill Crusher

Layout Of The Raw Mill Crusher. Flow chart crusher plant hermans wohnzimmer ch Flow Chart For Tph Crusher Plant Cone Crusher Flow Chart Of Crusher Plant Tph Flow chart of crusher plant tph the odgensburg plant was constructed on a large scale and included what was probably the largest orecrushing mill in the world at the time this mill pulverized the large chunks of ore that came ...

NOx Control Technologies for Thermal Power Stations Factsheet

of coal is added (see Figure 2: Layout of LNB, OFA and SNCR system in a pulverized coal power plant). This staging reduces peak flame temperatures resulting in lower NO x formation. NOx Control Technologies for Thermal Power Stations 3 27/07/18 5:03 PM

PA Fans, ID Fans, Draught Fans, FD Fans, SA Fans in ...

· In power plants, the PA fans supply air for conveying of the pulverized coal from coal mills to the furnace area. These primary air fans produce a high pressure to push the coal and air mixture through pulverizer into the furnace. The most common configuration of the draught fans used as a PA fan is the backward curved centrifugal fan. In power plants the PA fans play an important role in ...

(PDF) Relationship between Particle Size Distribution of ...

Figure 1: Mill (pulverizer) and combustion chamber layout (after [2]). impact of quality of feed coal, impact on emissions, and carbon content of fly ash and bottom ash.

JLandT Railroad: Paper Mill Complex...

Apr 07, 2014 · Well I have officially started the new Paper Mill Complex, after a quite a few design changes bouncing of ideas between fellow modellers, and some long hours on AnyRail I've come up with the following design. The design almost follows the original north side of the layout and the old Intermodal Terminal. This has been quite a good little win as ...

Improving Coal Pulverizer Performance and Reliability

BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it. Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and ...

Use of Coal Drying to Reduce Water Consumed in Pulverized ...

CONSUMED IN PULVERIZED COAL POWER PLANTS FINAL REPORT December 2, 2002 to March 31, 2006 by Edward K. Levy ... 1 Schematic of Plant Layout, Showing Air Heater and Coal 2 Dryer ... 67 Effect of Coal Moisture and Coal Type on Mill Power . 62

Pulveriserpower plant ppt | Furnace | Combustion

Typical Combustion Reaction Velocity ( Flame Speed) of Pulverized Coal : Effect of Ash Fraction 30%VM 5 % Ash 30%VM 15 % Ash 30%VM 30 % Ash 30%VM 40 % Ash F l a m e s p e e d m / s A/F ratio Typical Combustion Reaction Velocity ( Flame Speed) of Pulverized Coal: Effect of VM Fraction 30%VM 5 % Ash 20%VM 5 % Ash 15%VM 5 % Ash F l a m e s p e e d m / s A/F ratio .

Developing a state of the art construction

Belman Design solution. Belman Design in worked closely with the EPC contractor to consider all of the operating and design parameters and developed a new state of the art Expansion Joint engineered specifically for this appliion. This was the first very time a company engineered a product for this appliion on this plant.

Latest Posts

- Gamzen معدات البناء

- حار بيع خام الكروم إثراء المعدات

- كسارات الفك من الحجر الجيري

- غربال نوع التغذية آلة سحق الحجر

- الأيرلندية كسارة الحجر المنقولة

- حزام ناقل الرمال التعدين

- رسوم معدات الفصل المغناطيسي خام الحديد

- حجر محطم السعر كبير

- 250 طن ساعة المحمول محطم

- أمام منزل مثل الصخور المكسيكية

- تجفيف المواد الطينية و التحجيم

- إنتاج وتجهيز متناهية الصغر كربونات الكالسيوم

- أين يمكنني شراء حجر جيري مكسر في الفلبين

- آلة قطع الحجر للبيع في كينيا

- Track With Chassis Crusher

- Td China Mining Belt Conveyor Manufacturer Supplier

- Japan Technology Stone Crusher

- Understanding Clinker Liquid Phase

- To Separate Gold From Stone

- Crusher Plant Urgent Job Vacancies

- What Is Impact On Section Industry Economy In Coal Scam

- Mill Mill Shell Traylor

- Best Choice Ball Mill

- China Small Scale Jaw Stone Crushing Machine

- Pisau Crusher Besar

- China Mining Equipment Mixe Grinder Price 2019

- Small Grinding Mill For Chemical Montenegro

- Wholesale Suppliers Ball Mill

- Model Hz 1012 6 X 8 Delta Duplex Jig Mineral Concentrator

- Crusher Enterprises Page 3