Cyclones Mineral Processing Principles

cyclones mineral processing principles

cyclones mineral processing principles YouTube. Feb 14, 2016 General Principles of Mineral Processing Springer. Abstract. Metallurgy, Get Price; dense medium processing cyclone foodtribe. dense medium processing cyclone dense medium processing cyclone Processing Feldspar dedied to the mineral processing Dense Medium Cyclone Principles . Get ...

cyclones mineral processing

mine2810 mineral processing screens and cyclones energy and size reduction, lecture 3 classifiion and physical separation, dewatering representing sizing data more on screens bond milling work index closing the circuit more on cyclones particle separation gravity separation, ease of separation, types of separator mineral sands.

Mineral processing

Mineral processing can involve four general types of unit operation: ... gas cyclones, hydrocyclones, rotating trommels, ... in principle, relay on any other factors such as particle weight or shape. In practice, particle size and shape can affect separation efficiency.

The dense medium cyclone – past, present and future ...

· Aspects reviewed include the process principles, process models, the importance of medium behaviour, particle size limitations, process analysis, instrumentation and control, and increases in scale. Particular attention is given to the potential for the use of larger cyclones at lower heads in mineral separations, as practiced in the coal industry.

Introduction to Mineral Processing

Introduction to Mineral Processing 5 Liberation and Comminution Liberation In order to separate the minerals from gangue (the waste minerals), it is necessary to crush and grind the rock to unlock, or liberate, valuable minerals so that they are partially or fully exposed.

cyclones mineral processing principles

cyclones mineral processing principles. Cyclones mineral processing principlescyclones mineral processing principles africarhirecoza hydrocyclone wikipedia a hydrocyclone is a device to classify, separate or sort particles in a liquid suspension based the geometry of the cyclone involvesinlet shape and area, cyclone in mineral processing, hydrocyclones are used extensively both to classify up

Guide of Cyclone Separator

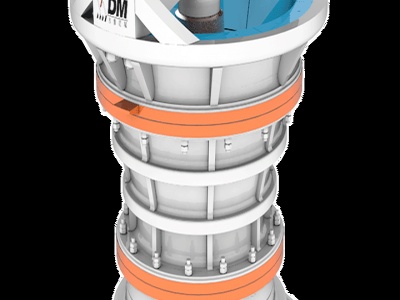

· Cyclone separator (Hydrocyclone) is a kind of classifiion equipment widely used at present because of its high classifiion efficiency, small floor space and low price. It can be applied in the mineral classifiion, sewage treatment, slurry concentration, desilting and .

Classifiion and centrifugation | FLSmidth

A cyclone, also known as a hydrocyclone, is a centrifugal device with no moving parts. It can be used to concentrate slurries, classify solids in liquid suspensions, degrit liquids, and for washing or cleaning solids. A hydrocyclone can perform ultrafine separations and .

Better separation: CycloStack CycloWash | FLSmidth

Enhance cyclones' separation and desliming capabilities with our patented, lowcost CycloWash device. Our KREBS CycloStack attachment is designed for use in solids dewatering appliions, and can be attached to the bottom of a standard cyclone to minimise the moisture content in the cyclone underflow. The attachment provides a lowcost ...

Cyclones

Metalliferous Mining Processing Cyclones Resource Book. CYCLONES 2222 ... Classifiion is a method of size separation of a mixture of minerals on the basis of the velocity with which the grains fall through a fluid medium (usually water). Cyclones utilise centrifugal

Classifiion Cyclones | Mineral Processing Equipment

Achieve superior quality classifiion in all mineral processing appliions with Multotec's range of classifiion or ceramic wear resistant linings protect the cyclone's inner – contributing to extended life of equipment.. Multotec equipment is installed in .

Lecture 11: Material balance in mineral processing

Key words: Material balance, ball mill, hydro cyclone, flotation. Preamble An important aspect of any mineral processing study is an analysis of how material is distributed whenever streams split and combine. This knowledge is necessary when a flow sheet is being designed

Principle of Operation of Hydrocyclone

· Principle of Operation of Hydrocyclone. The Principle of Operation of Hydrocyclone is, in simple terms, the forces of gravity and centrifuge to separate large or heavy particles from smaller and lighter one. When sized correctly will "cut" like the 'real cyclone' below VS the imaginary 'ideal' one on the left. A hydrocyclone (often ...

I. PRINCIPLES OF EXTRACTIVE METALLURGY

Principles of Extractive Metallurgy Training Course on Mineral Processing and Nonferrous Extractive Metallurgy June 30 July 5, 2008 Rakesh Kumar National Metallurgical Laboratory Jamshedpur 831 007 Resources for metals Natural Resources Gold is found in native state Aggregates of minerals .

I. PRINCIPLES OF EXTRACTIVE METALLURGY

Principles of Extractive Metallurgy Training Course on Mineral Processing and Nonferrous Extractive Metallurgy June 30 July 5, 2008 Rakesh Kumar National Metallurgical Laboratory Jamshedpur 831 007 Resources for metals Natural Resources Gold is found in .

Cyclones

Multotec hydrocyclones are used across the world for appliions in mineral processing, manufacturing, food processing, waste water treatment and other industries.. This industryproven product range of classifiion, dense medium and tailings dam cyclones has been optimised over hundreds of appliions across the world to improve classifiion efficiency, provide greater lifespan .

Latest developments in cyclone technology: Mineral ...

· (2003). Latest developments in cyclone technology. Mineral Processing and Extractive Metallurgy: Vol. 112, No. 1, pp. 1012.

Cyclone Separator Working Principle (Dust Separator ...

Introduction. Cyclonic separation is a means of separating different liquid phases (different liquid densities), or, separating particles from a gas separators often form part of a precleaning stage prior to a gas or liquid being discharged. This article focuses on the gas cyclone separator. Cyclone Separators. What's in a Name? A cyclone separator has several colloquial ...

Dense Medium Separation

• Simple process control (, medium density control); and • Simple machinery (, screens, pumps, cyclone or bath). DMS TECHNOLOGY The DMS process relies on a medium of specific density (specific gravity) that is between the density of the minerals targeted for separation. The form of the medium has changed throughout the years,

The dense medium cyclone – past, present and future ...

Aspects reviewed include the process principles, process models, the importance of medium behaviour, particle size limitations, process analysis, instrumentation and control, and increases in scale. Particular attention is given to the potential for the use of larger cyclones at lower heads in mineral separations, as practiced in the coal industry.

AMIT 145: Lesson 2 Classifying Cyclones – Mining Mill ...

Large cyclones (>660 mm) use shorter cylinder lengths. Inlet Feed Designs [image 14529] Cone Section. Cone angles vary from 6 ° to 90 ° 20 ° cone angle has been the standard; however, 10 ° is common for cyclones in the mineral industry. High cone angles are typically used to achieve very coarse particle size separations

Latest Posts

- الكوارتز الفلسبار الذاتي طحن مطحنة الكرة

- بيع خام الدياتومايت

- هيلغا الحزام

- بيع القديم مثبت الطريق الحصى

- كيفية الحد من النفايات الزائدة من مطحنة الفحم

- بيع الحزام

- غسل خطة التعدين

- كلمة خام الحديد في اليونان

- معيار حجم المخروط

- كسارات متنقلة للبيع في الإمارات العربية المتحدة

- مرفق تمويل معدات البناء

- باركر القديمة كسارة الفك المحمولة دليل التشغيل

- الكاولين مطحنة الكرة

- مهندس إنتاج الأسمنت الأبيض

- ناسك كسارة الحجر صاحب الاتصال

- Hammer Mill With Cyclone

- Burr Grinders Quality

- Skull Crusher Cheats

- Sebaliknya Pabrik Coating Video Bola

- Mining Quaries In Pakistan You Tube

- Steel Ball Dealer In Patna Bihar

- Di Jual Murah Crusher Java Raw Jakarta Surabaya Agustus

- Spares Parker X Jaw Crusher

- High Chrome Crusher Parts

- Mini Sweet Sorghum Roller Mill Crusher For Sale

- Of Gold Miners In Accra

- Stainless Iron Ore Garlic Crusher

- Limestone Jaw Crusher Supplier In Sri Lanka

- Pet Crusher Machine In Indonesia

- Stone Powder Machine