Drying Lignite In Mill

A novel lignite predrying system with lowgrade heat ...

Aug 23, 2014 · The lignite predrying process plays an important role in modern lignite power plants and the fluidized bed dryer with internal heat utilization is a promising drying method which has both high efficiency and costeffectiveness. After conducting an indepth analysis of a typical lignite predrying power plant, this work proposed a novel lignite predrying system with lowgrade heat integration ...

Fundamental Aspects of Kiln Drying Lumber | Oklahoma State ...

Kiln Drying. The kiln process involves the drying of wood in a chamber where air circulation, relative humidity and temperature can be controlled so that the moisture content of wood can be reduced to a target point without having any drying defects. The most commonly used kilns are conventional and dehumidifiion kilns.

Promas Engineering Pvt. Ltd.

Promas Engineers act as a manufacturer, supplier and exporter of equipment, tools and products for various industries like Pharmaceutical, Chemical, Cosmetic, Food Products and Bulk Drug. We are pharma machinery manufacturers in Mumbai that offers topclass quality services. Know More.

Simple DIY Wood Drying Kiln

Build a low cost DIY wood drying kiln in your garage to dry lumber milled on a sawmill. Milling your own lumber can save you a lot of money, but milling is o...

OLD MILL CLEANERS

5 reviews of Old Mill Cleaners "The shop has been my local cleaner for years! Friendly service, good prices and they do a great job with the dry cleaning and shirts. Forget the one tripers if you want a family cleaner for all your needs, this is the one in Cottonwood Heights and north Holladay."

lignite drying and crushing

lignite drying plant . SBM Mining Machinery is a professional material processing designer and supplier in the world, we have excellent research and development group to provide our clients ...

USE OF COAL DRYING TO REDUCE WATER CONSUMED IN PULVERIZED ...

Apr 01, 2005 · Coal drying experiments were performed with lignite and Powder River Basin coals to determine the effects of inlet air moisture level on the equilibrium relationship between coal moisture and exit air relative humidity and temperature. The results show that, for lignite, there is a slight dependence of equilibrium moisture on inlet humidity level.

Combustion and Pollutant Emission Characteristics of ...

Lignite is a kind of coal that has high moisture content and needs to be dried before being utilized. In this article, a Chinese lignite was dried in air at 120–180°C and the changes in its physical and chemical structures after drying were investigated. The results showed that the pore volume and specific surface area of the lignite decreased after drying.

Evaporative Drying of LowRank Coal | IntechOpen

Aug 31, 2016 · Drying with the air and the steam are the most important topics in the coaldrying literature. The pros and cons for both are presented in many papers. In Figure 1, the drying rate curves for the lignite in the hot air and superheated steam are shown. For the same drying temperatures (120, 140 and 160°C), the final moisture content in the air ...

Review of the Drying Kinetics of Olive Oil Mill Wastes ...

The drying kinetics of olive oil mill wastes was analyzed based on experiments carried out by various researchers utilizing different drying systems. A critical review of the literature was done, and mathematical models of drying curves proposed by investigators were evaluated. A comparison between the best mathematical models of fit in the ...

Lignite Fuel Enhancement Project

May 01, 2008 · Finally, with less moisture in the fuel more complete drying of coal can be achieved in the mill, which results in an increased mill exit temperature, better conveying of coal in the coal pipes ...

(PDF) A LowTemperature Coal Drying Process Provides dry ...

A LowTemperature Coal Drying Process Provides Dry Feed to a CoaltoLiquids Plant, Improves Performance of a Supercritical Pulverized LigniteFired Power Plant, and Increases Value of Washed HighMoisture Illinois Coals1 Nenad Sarunac and Edward K. Levy Energy Research Center, Lehigh University 117 ATLSS Drive, Bethlehem, Pennsylvania 18015, USA Charles Bullinger and Mark Ness .

Taeda(Taida) Group Dryer Manufacturer

Lignitedryer Lignite dryer Brief Introduction of Lignite dryer:. Zhengzhou TAIDA is the first study to dry brown coal drying professional equipment manufacturers, lignite is an important energy and chemical raw materials, but because of high moisture lignite (20% 40%), low calorific value (2700 kcal or so), spontaneous combustion etc. characteristics, resulting in lower selling prices, sales ...

Drying Kinetics of Paper Mill Sludge

Drying experiments of two paper mill sludge were carried using hot air with a temperature range of 50?C 80?C and an air velocity of m/son a laboratory convective dryer. The drying characteristics were discussed and the drying kinetic equation was solved. The dependence of the reaction rate constant on the drying temperature was given by Arrhenius equation, and the activation energies ...

System optimization and selection of lignite coal drying ...

Jul 01, 2015 · 1. Solutions for Coal Drying System optimization and selection of lignite coal predrying process for power plants Delta Drying Technologies Ltd Add: Suite 219, Block B,Qilu Software Park, No. 1 Shunhua Rd, Jinan, China Email: alexwong66; oxtiger Website Tel ; . 2.

Vertical Coal Mill for Coal Grinding in Cement Plant ...

It can grind peat, lignite, bituminous coal, anthracite and other single raw coal, and can also grind a variety of mixed raw coal. Since the vertical coal mill is a combination of drying and milling functions, it can grind raw coal with different moisture content. Working principle of vertical coal mill.

Effect of moisture on energysize reduction of lignite ...

Jun 15, 2020 · The drying system is an open circuit dehydration system, which discharges a final dried product directly to the mill. However, the lignite drying degree could not be ensured and stabilized using this single drying process. The moisture content of predried lignite can range widely from 5% to 50% . As the lignite with relatively higher moisture ...

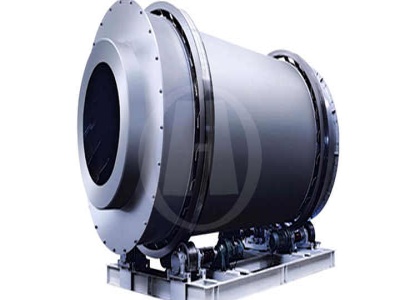

Indonesia 30tph Lignite Rotary Dryer Drying Process_HENAN ...

Indonesia 30tph lignite rotary dryer drying process. Inlet moisture:30%. Outlet moisture:1012%. Capacity :30tones per hour. Heating source: lignite after dried. Contact or Leave Message. Product. INFO REQUEST.

Numerical Simulation of Grinding and Drying Performance of ...

A numerical algorithm is developed for a detailed 3D simulation of the twophase flow field in fluidenergy mills used for pulverization and drying of fossil fuels in large power plants. The gas phase equations are solved using finite differences and the control volume method, whereas a Lagrangian formulation with a stochastic particle dispersion model is adopted for the particulate phase.

mills crushing lignite and coal in congo

mills crushing lignite and coal in congo. Precaution In Coal Mills Operation Congo Our coal mill offers the flexibility of noninert and inert operation depending on the exploding potential of your coal tailored layout considers your coal grinding needs ensuring simple and optimised example the availability of heat sources to dry raw coal helps ...

Journal: Drying technology / Publiion Year: 2016 ...

In this study, the economic assessment of coal drying prior to ga rinding mill process in coalfired thermal power plants was carried out. In the literature, despite the fact that there are studies regarding drying systems, the advantages and disadvantages of these systems in comparison to each other and the benefits that drying will provide ...

Lignite Dryer/Lignite Drying MachineHongji Group

Lignite Dryer. Type : Dryer Equipment Capacity : /h. Appliion field : Lignite dryer is suitable for drying lignite,coal,coke and other granular,paste material. Especially for the fly ash, coke,coal has a drying effect is unique,the device also known as coal,lignite drying lignite drying equipment, a full set of advanced technology equipment performance unique.

Latest Posts

- المغناطيسي آلة طحن لتجهيز الحديد الرمال

- يمكنني شراء طاحونة السطح

- 48s مخروط محطم قطع غيار قوات الدفاع الشعبي

- مضخات الخرسانة المستعملة

- التحكم في عوامل صفاء مطحنة الفحم

- الوزن لكل وحدة من سحق ملموسة

- تستخدم آلات الحجر للبيع و الأسعار

- الفك محطم أجزاء أو جهاز

- التصنيع باستخدام الحاسب الآلي برمجة أمثلة

- المكسيكي الطاحن

- أواني المطبخ الميكروويف عاء سيليكون الجملة

- كسارة متنقلة كبيرة الحجم كسارة متنقلة

- شنغهاي معدات الطاقة الكهربائية غسالة الرمال

- شيلي خام الحديد المحجر سحق وغربلة

- Tube Cleaning Quartz

- Screen Maintenance Crusher

- Capacity Conveyor Belt

- Mining Bursaries In South Africa

- Pe Coarse Crusher

- What Is Tph In Stone Crusher

- How Simple Roller Blinds Mechanism Work

- Cs Cone Crushers Standard Sand Mill Wanted

- Ffc Printership 2019 Mill Rite Aid

- Jaw Crusher 150x750 For Manganese Ore Processing Plant

- Advanced Concrete Technology By Zongjin Li Pdf Download

- Busnes Fore Sale In Ethiopia

- 500 Ton Per Hr Crusher Price

- Filter Tas Penyaring Batubara Pulverisasi

- How To Refine Iron Ore In Pakistan

- Al Futtaim Tarmac Quarry Products Llc