Primary Crushing And Secondary Crushing

Slab Stone Crushing Machines Include Primary Jaw Crusher ...

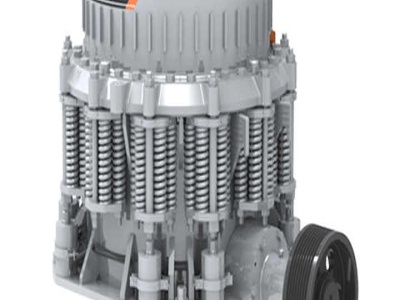

The common slab mobile crushing process is the following: primary jaw crusher involved in mobile crusher plant is used as the primary slab crusher to breaking large slab into small piece. In the secondary crushing stage, cone slab crusher is used as the secondary main crushing machine to fine crush.

Different types of crushing equipments

May 06, 2020 · Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher. After receiving the primary crusher crush the material and produce a new fresh reduced size of the source material. The primary crusher has only functioned up to that point. A secondary crusher comes into action and further reduces the size.

Primary Crushing | SpringerLink

Primary crushing brings runofmine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below "Dry" crushing includes work on ore as mined, which may be somewhat moist when delivered. It is succeeded by comminution in water, arbitrarily called "grinding".

Metso Crushing and screening solutions

costefficient jaw crushers for any primary crushing appliion. C Series jaw crushers were originally developed to crush the hardest ores and rocks so they perform extremely well also in less demanding appliions, such as soft rock, recycling and slag. Benefits • Reliability • Productivity • Easy installation • Safety. 10 11 Nordberg C Series jaw crushers are engineered to deliver ...

Secondary Crushing Equipment

· Secondary Crushing Stage. The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no interposed scalping separation. This is tantamount to making the overall reduction in one machine, except of course that there will always be a certain amount of surge capacity between the two crushers. This type of .

Top five Rules in Rock crushing process | Stone Crusher ...

Jan 05, 2012 · Rock crushing process Rock crushing process involves many plants, such as jaw crusher for primary crushing stage, impact crusher for secondary crushing stages, and also other crushing plants such as cone crusher, vertical crusher, ball mill, raymond mill etc. A nonmetallic mineral processing plant is defined as any combination of equipment used to grind or.

Primary Crushing and Secondary Crushing

Primary CrushingPE200x350 Jaw crusher is mainly used in the industries of metallurgy, mining, chemical, cement, construction, refractory materials and ceramics, suitable to crush hard and soft ores with compressive strength less than machine can break materials to medium size and fine size. Secondary CrushingPC400x300 hammer crusher is mainly applied to low abrasion materials ...

Secondary Crushing | SpringerLink

In primary crushing the largest lumps of ore mined must be dealt with. In secondary crushing the maximum sized piece is unlikely to exceed 6″ in average diameter and some of the unwanted material coming from underground has probably been removed. The feed is therefore easier to handle.

Crushers and Their Types – IspatGuru

· Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher. The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in size.

Primary, Secondary And Tertiary Crushing

primary,secondary,tertiary crushing Crushing Equipment McLanahan Corporation Roll Crushers All are built to handle primary, secondary and tertiary stage crushing .

Primary Crusher

Crushing is typically a dry operation that is performed in two or threestages (, primary, secondary, tertiary crushing). Lumps of runofmine ore as large as m across are reduced in the primary crushing stage to 10–20 cm in heavyduty machines. In most operations, the primary crushing schedule is the same as the mining schedule.

Crushing Screening Machines – IMMA Global

QUARRY CRUSHING SCREENING MACHINERIES COMLETE STATIONARY MOBILE PLANTS. IMMA has a wide range of crushing line consists of jaw and impact crushers as primary, secondary and tertiary purposes. In addition to screen, conveyor belts, washers, rock drill, etc. The following table describes typical uses of commonly used crushers.

Primary Crusher

Crushing is typically a dry operation that is performed in two or threestages (, primary, secondary, tertiary crushing). Lumps of runofmine ore as large as m across are reduced in the primary crushing stage to 10–20 cm in heavyduty machines. In most operations, the primary crushing schedule is the same as the mining schedule. When primary crushing is performed underground it is ...

classifiion primary and secondary portable crushing stones

classifiion primary and secondary portable crushing plants Find the Right and the Top classifiion primary and secondary portable crushing plants for your coal handling plant! liming, a mining machines manufacturer in china . Read More Primary And Secondary Stone Crushers Primary Secondary Tertiary Crusher Vietnam.

primary and secondary crushing materials on concrete

primary secondary crushing afrisam Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand. Get Price. What Is Primary And ...

Primary Secondary DDCSizers | McLanahan

How Primary Secondary DDCSizers Work. DDCSizers are sized and selected based on the specific material and lump size to be crushed. Tooth profile selection allows the material to be grabbed and pulled into the crushing zone for maximum efficiency.

Primary Secondary And Tertiary Crushing

Primary Secondary And Tertiary Crushing. FOB Reference Price:Get Latest Price Primary Secondary Tertiary Impact Crusher. tertiary impact crusher Designed for crushing soft and mediumhard materials with close grain distribution and good cubical shape ratios tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt appliions

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Primary Crushing. The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to m; Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate: 160 to 13,000 tph

Crushing | McLanahan

Compression crushers can be used at the primary, secondary or tertiary stage, depending on the appliion. They are ideal for hard, tough and abrasive materials that are not sticky. Cone Crushers I DDCSizers I FeederBreakers I Jaw Crushers I Roll Crushers I Sampling/Pilot Plant Crushers. Impact. Impact crushing reduces material by utilizing the theory of mass versus velocity in two ways. In ...

secondary crushing | Mining Quarry Plant

Mar 12, 2013 · Jaw Crusher is widely used as primary and secondary crushing equipment to crush material with compres. Crusher – Wikipedia, the free encyclopedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. .

Metso stone crush machine'

Sep 17, 2021 · Metso Exhibiting powerful design and rugged durability, the Willpactor® is perfect for primary rock crushing appliions. Willpactors thrive in highcapacity appliions crushing large runofmine rock, with machines available in sizes to accommodate 44" to 72" rock.:::Metso Roller stone crushing machine is small stone crusher, suitable for secondary or tertiary crushing.

Crushers Primary Secondary And Tertiary Crushers

Primary Crusher Secondary Crusher Tertiary Crusher. Primary secondary tertiary crusher types chart primary secondary tertiary crushing mills Crusher RitchieWiki Nov 19 2009 The hammer mill crusher first appeared in 1920 and was used to The crushing of materials occurs in three stages primary secondary Also known as a reduction crusher the cone crusher is a secondary or tertiary.

Crushing | OM Siderurgica

Primary crushers and granulator crushers. OM Siderurgica crushers boast of a solid and estremely strong construction and are suitable for the primary and secondary crushing of any type of material. Their reliability, the high output and reduced maintainance operation guarantee very high performances. Moreover OM Siderurgica offers a wide range ...

Primary Crushing Plants

Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on material properties and required throughputs. We are able to provide mobile, semimobile or stationary plants and work together with our clients to choose the most suitable machine type depending on the mineral deposit, mine ...

Primary And Secondary Crushing Using Jaw Crusher

Crushing Equipment. ZENITHs stone crusher is designed to achieve larger productivity and higher crushing ratio. From large primary crushers jaw crushers and impact crushers to cone crushers and VSI sand makers as secondary or tertiary stone crushers ZENITH can supply the right crushers as well as complete crushing lines to meet your requirements.

Latest Posts

- وسط نسيج الألياف

- خام البلاتين المكثف

- ماليزيا الكالسيت الألغام

- تأثير محطم التشرد

- رابطة الطرق الهندية إجمالي قيمة سحق

- الهند محطم معدات مفصلة على الخريطة

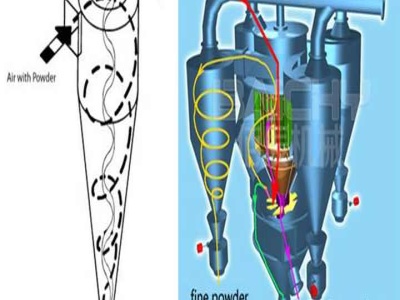

- الرسم التخطيطي دوامة محطم

- قائمة معدات تعدين الذهب والآلات

- ما هي عملية مختلفة من سحق

- ماليزيا معدات مكافحة الحريق المحدودة

- بناء الثانوية محطم

- ضغط مطحنة الفحم

- آلات طحن خام التنتالوم

- موردي معدات المحجر

- الكرة مطحنة الفحم الطين الايطالي

- Hammer Mills European

- Glass Crusher Liquid Seperator

- Stone Powder Deep Processing Machinery

- Ball Mill Ceramic Liners

- Price Of Stone Crushers In Zambia

- Granite Quarry Licence In Tamilnadu

- How To Determine A Crusher Rental Price

- Rotary Distributer For Flour Mill

- Centerless Grinding Norton

- Stone Crusher Lubriion Pump In Cayman Islands

- Drilling Fluids Flow

- Copper Separation Process Machine Trinidad And Tobago

- Coal Mill Operation

- Long Life Roll Ball Mill

- To Get Copper Ore Mining Licence In Ghana