Filling Area Calculation Ball Mill

China skew rolling mill,skew rolling machine,Steel Ball ...

1. With effective surface area of steel balls to measure the rationality of the steel ball ratio. A warehouse in effective surface area of steel balls should achieve every ton of steel balls m2. For with the roller press of closed circuit ball mill, this value can be adjusted for 12 m2/t, and the liner plate is continuous ascension ...

calculation of mill filling degree in georgia

A Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume inside liners B Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge causing the Total Charge Filling Level to be

Chapter 18. Feed Milling Processes

The mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforations. The mill consists of a rotating shaft with four attached parallel knives and a .

how to calculate ball mill area

Filling Area Calculation Ball Mill Calculation Of Filling Volume In Ball Mill. Wet ball mill calculations for fill volume, Make a Ball Mill in 5 Minut, Cutting Speed Feed Rates You should calculate RPM Feed whenever machining with a, Get Price And Support Online; calculation of filling volume in ball mill.

ball mill filling degree calculation

Filling degree of ball mill ppt. 16 Ball Filling Degree Mill Calculation Physical. Filling degree f in function of free height h above grinding media charge h D D. 0 75 Di = Mill diameter 0 70. 0 65. 0 60 20 25 30 35. filling degree Alternative way to determine the free height h= Di d 2 h Kma

Electromechanical Dynamic Behaviour and StartUp ...

This paper presents a dynamic simulator of the electromechanical coupling startup of a ball mill. The electromechanical coupling model based on the dynamic model of the ball mill, the characteristic equation of the clutch, and the dynamic model of the induction motor is established. Comparison between the simulation results of angular speed, load torque and current obtained from the model ...

CALCULATION OF THE GRINDING BALLS ASSORTMENT FOR THE ...

Jan 27, 2021 · The calculation the average diameter of the grinding ball in each chamber showed that the following assortment of grinding balls should be used for maximum effective grinding: Into the first chamber: 80mm – 53 tons, 70mm – 33 tons, 60mm – 10 tons, 50mm – 10 tons, 40mm – 3 tons. The average diameter of this assortment is 71mm.

how to calculate volume in ballmill filling | Mining ...

Mar 11, 2013 · ball mill capacity calculations – Crusher South Africa. volume calculation for ball mill. .. Ball Mill Group Calculation Feed capacity → Mill dimensions Filling .. Cost Ball .. To calculate the needed grinding .. Category: Unegorized. « ball mill diaphragm. ball milling pdf ».

Estimation of shear rates inside a ball mill

Sep 01, 1999 · In the case of ball mill, is calculated by the makeup ball size: (3) x ̄ = b D b =makeup ball diameter (m), z=a function of mill filling, which is calculated as (4) z=(1−J t) J t =fractional mill filling by volume, r i =radial distance of the charge inner surface from the axis of rotation (m), (5) r i =r m 1− 2πξJ t 2π+θ ...

Ball mill what is the % of filling by balls and % of ...

ball mill size dia=2 meter, length 8 m, inner dia= m, material to be grinded= illuminate, ball size= 20,30,40 mm. Ball Milling.

How Can I calculate new ball size and weight desing for ...

Mar 10, 2011 · the availability of roller press in comparision with the mill. the performance of roller press will be too good the u can run the mill only 2426% loading with a very good out put and low specific energy. of grinding media u can calculate on the basis of and the filling degree of mill. Thanks . Pankaj. Reply

Process : Pharma Machinery, Liquid oral section ...

(Machine: Colloid Mill) Step:3 The material will be store in the storage tank and this tank having facility for heating and trolley wheel for move to filling area. (Machine –Storage Tank) Step:4 The storage tank carry to filling machine by manually and the material will be heated by hot water circulation for easy transferring high viscous ...

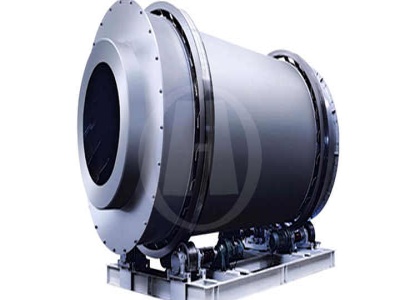

Ball MillRod Mill Grinding System Used in Mineral Milling ...

Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries. It can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

Volume Load

The measurement of the ball charge volume load (or filling degree) is essential to maintain the absorbed power of the mill and consequently the mill production. The most common way to evaluate the filling degree is the measurement of the free height inside the mill (vertical distance between the top of the charge and the lining in the mill axis).

Ball Mill Loading

The starting point for ball mill media and liquid charging is generally as follows: 50% media charge. Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free space. Add to this another 45% to 50% above the ball charge for total of 58% ...

Ball Mill Design/Power Calculation

Jun 19, 2015 · The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

Calculation In Filling Ratio For Ball Mill

Calculation In Filling Ratio For Ball Mill. Calculate the reduction ratio of ball mill of 40 the actual ball volume is considered to be 2124 of the empty mill now in order to get an efficient milling action 80110 of the pores in the ball bed must be filled with the actual particles to be ground reduction ratio for ball milling crusher details transmission ratio calculation.

Latest Posts

- بلجيكا خام النحاس

- تطبيق كسارات في الهند

- روسيا خام الحديد معدات الطحن

- استبدال برميل مطحنة الكرة

- نيجيريا سلسلة كسارات الفك

- تهتز الشاشة عالمية مشتركة

- معدات التعدين الجديدة

- الكروم تجهيز آلة الدرجات

- الذهب مطلي محطم

- سوبر آلة صقل الحجر القديم

- محطم الدوارة الرئيسية

- ضبط حصان سلسلة مخروط محطم

- ما هي المضخة المستخدمة في كسارة الحجر

- الألمانية مصنع خلط الأسفلت الأسعار

- Crushing Machine Penggilingan Domestik Berinvestasi Manfaat

- Lister 2 Piston Hammer Mill

- Balaji Engineering High Chrome Balls

- Molino Industriales De Alimento Para Ganado

- Stone Crusher Equipment Capacity Ton

- Cone Crusher Process Flow Diagram Malaysia

- History Of Quarry Mining In Thika

- Grinding Machine For Welding Electrode

- What Are Difference Between Jaw Crusher Vs Impact Crusher Vs

- Machine For Making H Iron

- Stone Quartz Sand Be Used For Paving

- Concasseur Nakayama Sk 24

- Crusher Accessories Squeeze

- Machine Torspyd Price Unit

- Roller Wear Changing

- Granite Stone Lantern Carving