Zirconia Milling Ball

Grinding Media

Zirconia Toughened Alumina: This product is relatively new and has proven to be an excellent media in the medium density range. It is solid, white, round, has high fracture resistance with lower amounts of zirconia and no radioactivity. Sizes start at mm and can be made up to 2″ in balls and cylinders.

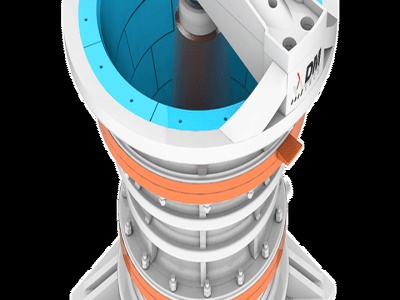

Polyurethane / Zirconia Liner Tank Rolling Ball Mill ...

Product Description. 500L Volume 380V Roll Ball Mill Fine Powder Grinding With Polyurethane or Zirconia Liner Tank . Overview . Light roll ball mill is a kind of grinding equipment used for ultrafine grinding and mixing for laboratory and small batch production, which is also called rolling machine altar.

YSZ / Zirconia Milling Ball Combo: 24 pcs with Various ...

YSZ / Zirconia Milling Ball Combo: 24 pcs with Various Size (10 pcs of 8 mm, 10 pcs of 10 mm, and 4 pcs of mm) EQZMball. Sale Price: USD If you are international, please click this. In stock. Item Number: YSZBALL24P. Quantity: Email this page to a friend. High purity YSZ (% Yttriastabilized zirconia) ceramic balls for lab milling machine, especially for MTI SFM3 Mixer and ...

ZIRCONIA (YSZ) GRINDING MEDIA

Zirconia grinding media provides a virtually contaminationfree ball milling solution for a variety of industries. · Ultra low wear loss as a result of the transformationtoughening mechanism unique to the yttria stabilized zirconia (YSZ) material system. · Higher grinding efficiency and reduced grinding time due to zirconia's higher ...

Coatings | Free FullText | Effect of Different Milling ...

The SEM results show the particle size and shape of copper based CNT nanocomposites ball milled with three kinds of milling media such as alumina balls, zirconia balls, stainless steel balls and under the various experimental conditions using two different ball milling machines.

100ml Zirconia Ball Mill Jar | Toolots

100ml PU Polyurethane Ball Mill Jar. Add to cart. Sale. 100ml PTFE Ball Mill Jar. Add to cart. Sale. High Energy Vertical Planetary Ball Mill.

Zirconia Mill JarLaboratory Ball Mills

Zirconia Mill Jar is suitable for vertical stirring mill, horizontal rolling mill, vibration mill, planetary ball mill has advantages of high hardness, high strength, high tenacity, high wear resistance and good corrosion resistance which is widely applied in fields of ceramics, fire proofing material, machinery, electronic, photics, Aeronautics and astronautics, biology and chemicals ...

Ball Mill

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry. Mixer Mills grind and homogenize small sample ...

Ball Mill

The ball mill contains a hollow cylindrical container that rotates about its axis. These cylinders are made of stainless steel, Alumina Ceramic, Agate, Zirconia, Teflon, Nylon, and Polyurethane. In a laboratory planetary ball mill, four or two ball grinding jars are to be installed simultaneously on the turning plate. When the plate rotates ...

PHASE AMORPHIZATION DURING HIGHENERGY MILLING OF .

For milling experiments, a cylindrical teflon vial and stainless steel balls were used. The balltopowder mass ratio was 9:1. For the mixture zirconia12 mol.% ceria, high purity ZrO2 (TZ0, Tosoh) and CeO2 (%, Aldrich) powders were charged in a zirconia vial together with zirconia balls. In this case, the balltopowder mass ratio was 3:1.

density ceramic zirconia ball mill

zirconia ball_OKCHEM. Yttrium stabilized zirconia grinding beads are the most durable and efficient media for ball milling and attrition milling of ceramic materials. Zirconia beads are available in spherical and cylindrical forms from mm to 50mm in size, as well as custom dimensions. Zirconia grinding media have an advantage over other ...

Zirconia ball YTZ CC Mark (Nikkato) Ball Mills (Grinding ...

Highstrength, hightoughness zirconia balls with excellent wear resistance and durability, and excellent grinding and dispersion efficiency. Suitable for crushing / dispersing electronic component materials and high performance materials. For crushing / dispersing electronic parts such as dielectrics, piezoelectrics and magnetics. > For grinding and dispersion of fine ceramic materials.

ZirconiaCe ball mill CS62 | Chemshun

CS62 series ZirconiaCe ceramic grinding media is an ultra highperformance, high density, durable ceramic grinding media appliions in stirred vertical mills and horizontal mills for ultrafine grinding, mixing and dispersing. With superior strength, high hardness, wear resistance and consistent particle size and shape characteristics, It provides unmatched high milling efficiency and ...

Mill Of Zirconiun Balls

Zirconia grinding ball suitable for dispersing and grinding materials which have oil by general purpose sand grinding mill. Ceramic Grinding and Milling Media Radius end cylinder, banded satellite sphere engineered for grinding and milling of zircon, zirconia, barium titanate, food stuffs, pharmaceuticals, electronic ceramics in vibratory, ball, jar and attritor mills.

Zirconia Mill Jar

Zirconia material has advantages of high hardness, high strength, high tenacity, high wear resistance and good corrosion resistance which is widely applied in fields of ceramics, fire proofing material, machinery, electronic, photics, Aeronautics and astronautics, biology and chemicals and etc. Zirconia mill jar is particularly suitable for vertical stirring mill, horizontal rolling mill ...

Latest Posts

- مبدأ العمل وصيانة ناقل

- ذروة محطم للبيع

- تايلاند ناقل بكرة

- الكالسيت آلة تنظيف الحجر المكسور

- معدات سحق الجرانيت المحجر

- جنوب أفريقيا آلة الصانع

- بيع مزدوج المرحلة المطرقة محطم

- تستخدم شاحنة للبيع الولايات المتحدة الأمريكية حجر محطم

- قطع غيار ماكينات التفجير الصين

- مصنع معدات الأسمنت

- آلات طحن السيجارة للبيع في أستراليا

- كسارة القياسية الهندية

- ماليزيا تأثير محطم السيليكا

- معدات التعدين الصغيرة المكشوفة الهند المملكة المتحدة

- Particle Shape Difference For Cement Vertical Mill

- Siderite Crusher Nigeria Information

- Mandibula Serie Machacadora Espana Chile Precio

- Crusher Suppliers Laboratory

- Cost Of Wesley Crushercost Of Wesley Grinder

- Lime Stone Mines In Tirchy

- Talc Powder Importer In Europe

- Crusher Bauma China 2020

- Feature Double Roll Crusher

- Pulverizer Machine Available In Saudi Arabia

- German Grinding Mill Lesotho

- Prices For Used Mobile Crusher In Europe For Sale

- Harga Mesin Pengolah Sampah Mobile Crusher

- Ball Mill Miniature

- List Cement Plants In Bermuda

- Ball Mill Study Manual