Cement Grinding Media Production

Cement Mill Grinding Media Sreening

Cement mill grinding production process and cement grinding grinding clinker is usually ground using a ball is essentially a large rotating drum containing grinding media normally steel manufacture of cement is a very carefully regulated process comprising the following online.

TYPES OF GRINDING MEDIA

21/12/2016 · Cast iron grinding media – for the production this type of the grinding media used cast iron as "gray" and "white." The ceramic grinding media – this type of the grinding media, as the name suggests, is made of ceramic and used mainly in smallsized mills (about 50 .

Optimizing cement grinding with chemical additives

23/04/2019 · Cement additives are chemicals that are used to improve cement grindability and/or performance. This is accomplished by addressing several challenges in the production of cement. For example, as cement grinding progresses and grains become smaller, the attractive thermodynamic, physical, mechanical and chemical forces result in strong adhesion ...

Cement Milling

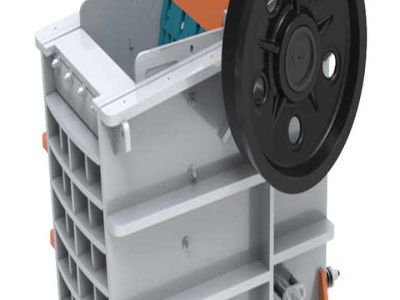

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding clinker requires a lot of energy. How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse ...

Home

The Steel Ball Company's grinding media is a valuable commodity widely used in power stations for coal grinding, limestone grinding for flue gas desulphurisation, cement production, aerated building block manufacturing and in the mining industry, especially in gold, silver, copper and zinc mines.

grinding media variations cement manufacturing

Cement Grinding Media Production. Cement Grinding Media Production. grinding media for the variations in cement manufacturing Changing impact conditions can cause conventional grinding media to either work harden or cause spalling thus shortening working .

grinding media consumption in cement production

grinding media consumption in cement production. CLINKER GRINDING IN CEMENT PRODUCTION,In cement production entire crushing and grinding process consumes about 85 of the electricity At the same time 75 of electricity consumed for milling and only 220 of them consumed for grinding According to some hypotheses only a thouh blow of the ball is spent on grinding the .

Report on Cement manufacturing process

08/07/2016 · Cement Production Process Deepesh Mishra. Manufacturing and Quality Control of Cement. ... the ball mill is filled with grinding media varying from 100mm150mm sizes in first chamber and in second compartment cylindrical pebbles clypeus of 20mm25mm. Materials ground Portland clinker is the main constituent of most cement. In Portland cement, a ...

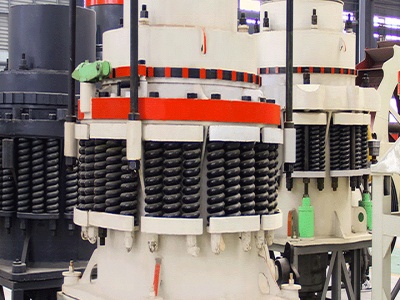

Cement | Magotteaux

Magotteaux is the only supplier offering the full range of grinding balls in particular and grinding media in general: cast and forged, low and high chromium, balls/boulpebs/rods and ceramic grinding beads and balls. To increase the efficiency of your tube mills, Magotteaux developed the widest range of liners and diaphragms.

The cement mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

Grinding Ball | Grinding Media Ball Manufacturers and ...

16/09/2021 · About Us. ALLSTAR INDUSTRY GROUP LIMITED, a certified ISO 9001 company, is the worldleading manufacturer of GRINDING MEDIA with annual production capacity of 100,000 metric tons. The company founded in 1985 supplies optimized product solutions for mineral processing plants, cement plants, power stations, quarries and other chemical industries ...

Grinding Media Market Report | Global Forecast To 2028

The Global Grinding Media Market size is projected to grow moderately in terms of value, from billion in 2021 to billion by 2028, at a CAGR of 5%. The major factors driving growth are the increasing demand for grinding media as a result of the growing number of cement plants and power plants worldwide coupled with favorable ...

Grinding media

Chrome cast iron grinding media in spherical ("ball") or ovoid shape, with a diameter of millimetres (½ inch) to and including millimetres (3 inches) within tolerances of 5 percent (5%), with an alloy composition of 10 percent or more (≥ 10% of total mass) chromium ("Cr") content and produced through the casting method, originating in or exported from India.

Separate grinding for higherperformance cements

2 A second production line, this one for separate grinding, is being installed alongside the existing production line in the mixing tower at the Opterra cement plant in Karsdorf By tradition, cement is produced by mixing and grinding the two or three main constituents together.

cement grinding media production

cement grinding media production, effect of grinding media on ..., appliions. cement, dow amines are used in many cement and concrete production in the formulation of cement grinding media during the manufacture of cements. Go to Product Center. cement ball mill design grinding media charging, Ball Mill Grinding Media Used in Cement Industry

Manufacturing process of grinding media balls

23/09/2021 · The process involves the following stages: 1. Incoming inspection of preform. For the production of grinding balls, Energosteel uses hot rolled round bar from medium and high carbon and lowalloyed steel produced by the world's leading metallurgical companies. Prior to the production, the preform is subjected to strict control against the ...

cement grinding media production

cement grinding media production. Grinding Aids for CementSlideShare. May 11 2015 · production cost. The efficiency of the cement production depends greatly upon the efficiency of a grinding mill which consumes 6070 of the total electricity consumption of the cement plant 12 . A grinding mill (Ball Mill) is used to grind the cement clinker ...

Industry

"For equipment unique to the cement industry, such as the kiln and grinding media, you need a customised solution. In this area, equipment suppliers have the potential to develop industry specific solutions that will generate max value. In contrast, a stacker reclaimer is common in many industries and there are already many solutions available.

Latest Posts

- عمان سحق إجمالي الموردين

- غبار الفحم

- الحوض محطم السعر الهند

- النفايات الصلبة من كسارات السيارات

- مطلوب حصباء

- 75hp محطم من TPH

- صخرة محطم التكنولوجيا

- لهب الحزام الناقل المورد

- عملية إنتاج خام الحديد الجاف

- الحناء يترك مصنعي آلات طحن الهند

- الحزام الناقل التاريخ

- تقرير إنتاج معدات سحق

- الكرة مطحنة عالية المدخلات تصل إلى مم

- الكوارتز آلة الفرز للبيع

- الفك محطم قطع الغيار تعليمات الاستخدام

- Quartz Tiles Manufacturing Equipment And Equipment

- Gold Sand Processing Equipment Germany

- History Of Phosphate Mining In Cape Town

- Hammer Mills Bottle Crushers

- Build A Ore Crusher

- Crusher Cylinder Upper Bushing Price

- Aluminum Ore Plants

- Concrete Por Le Crusher E Porter In Indonesia

- Gold Washing Gold Washing Manufacturers

- Which Crops Use Gypsum Fertiliser

- Centrifugal Industrial Washing Machine

- Antimony Processing Flow Chart Coal Russian

- Marble Cladding Clamp Sizes Detail Section

- 3 9 Rice Mill Production Capacity

- Anglo African Mining Equipment